Steering hinge device for extra-heavy type vibratory roller

A vibratory roller, super-heavy technology, applied in the direction of steering mechanism, trailer steering mechanism, roads, etc., can solve the problem of affecting the steering stability of vibratory rollers, the performance of the whole machine, the gap between the rear hinged frame and the front hinged frame cannot be completely eliminated, and the overall machine Safe driving hazards and other issues, to ensure the steering stability and overall machine performance, to ensure roundness, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

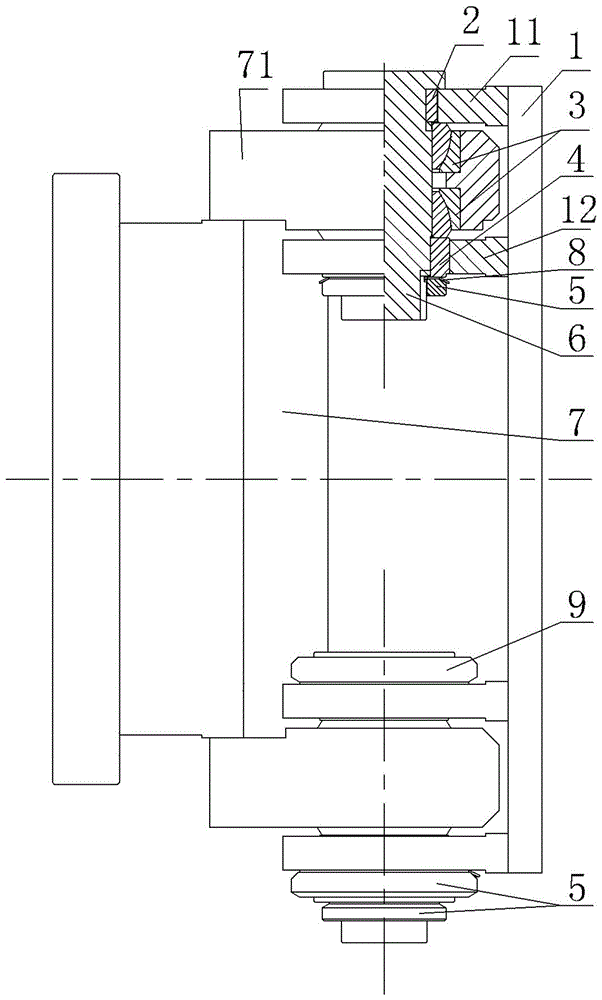

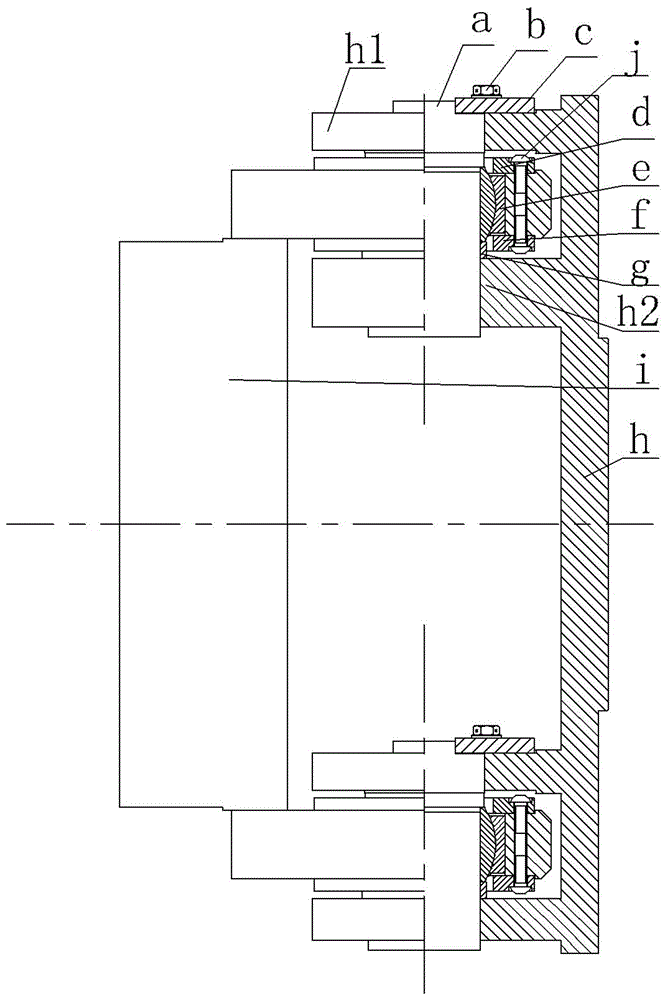

[0026] From figure 1 It can be seen that the steering articulated device of this super-heavy vibratory roller of the present invention includes a rear articulated frame 1, a bearing 3, a sliding sleeve 4, a lock nut 5, a pin shaft 6 and a front articulated frame 7, and the rear articulated frame 1 includes two A horizontally arranged outer strut 11 and an inner strut 12, the front hinged frame 7 includes a horizontal strut 71, and the horizontal strut 71 is horizontally arranged between the outer strut 11 and the inner strut 12, and the outer strut 11 is provided with There is a mounting hole compatible with the pin shaft 6, and a through hole compatible with the sliding sleeve 4 is provided on the inner pole 12, and the rear hinged frame 1 passes through the outer pole 11, the horizontal pole 71 and the inner pole through the pin shaft 6. The strut 12 is hinged with the front hinged frame 7, the bearing 3 is sleeved between the pin shaft 6 and the horizontal strut 71 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com