Method for handling and modernizing ropes in an elevator and arrangement for dismantling ropes of an elevator

A rope and elevator technology, applied in transportation and packaging, elevators in buildings, lifting equipment in mines, etc., can solve problems such as loss of traction wheel friction, unbalanced elevator system, etc., and achieve energy saving and elevator performance. The effect of reducing power consumption and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

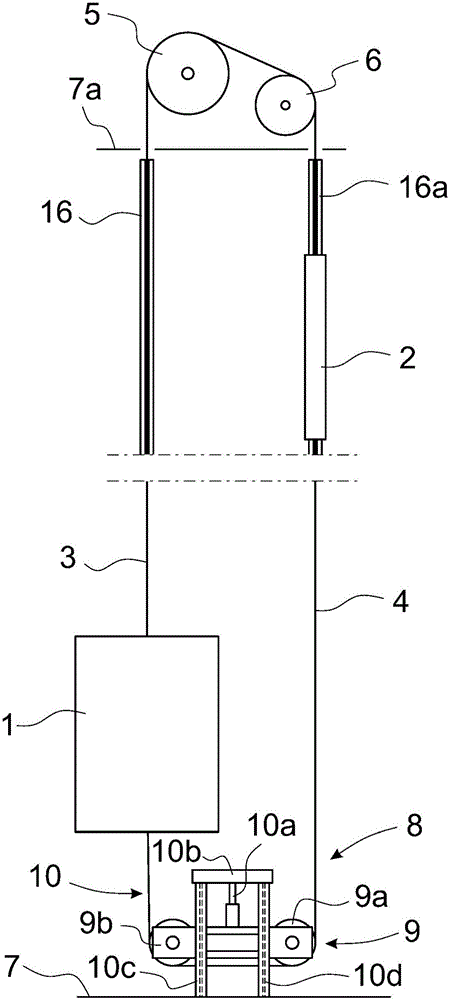

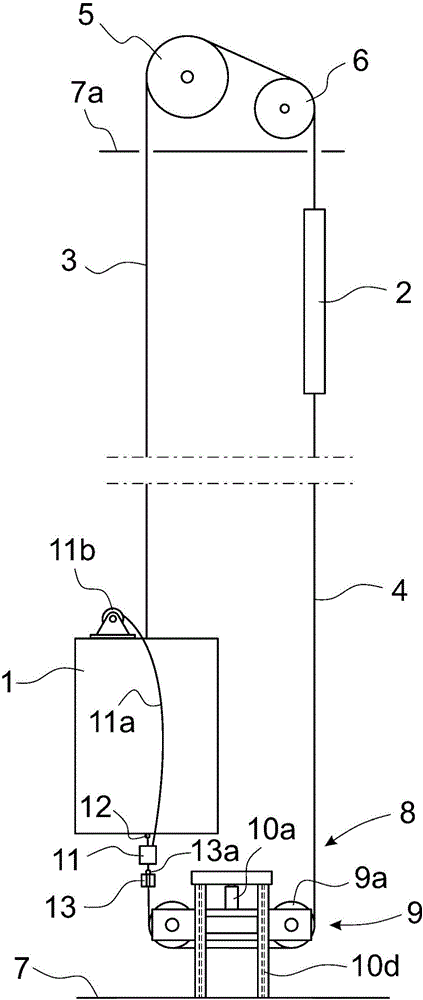

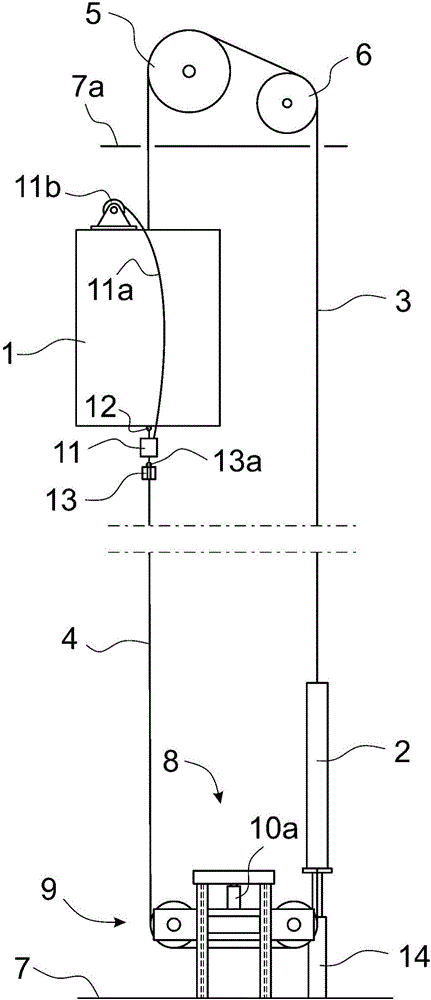

[0020] figure 1 A typical elevator roping arrangement used in high-rise buildings is presented in simplified and diagrammatic side view. For clarity only, the upper and lower ends of the elevator installation in the elevator shaft are presented. A typical elevator installation comprises an elevator car 1 and a counterweight 2 traveling up and down guided by its guide rails 16, 16a. For clarity, figure 1 with 10 Only the elevator car guide rail 16 and counterweight guide rail 16a on the side of the car and counterweight are shown in figure 1 In , only the guide rails 16, 16a at the upper part of the elevator shaft are shown. The elevator car 1 and the counterweight 2 are connected together by a bundle of parallel hoisting ropes 3, the first ends of which are fastened to the elevator car 1, or directly into the car 1 Or in the frame-like sling that supports the car 1. For clarity, figure 1 The sling is not shown in this nor in the other drawings. The hoisting ropes 3 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com