Mn-Cu-Al thermosensitive damping alloy material and preparation method thereof

A damping alloy, mn-cu-al technology, applied in the field of materials, can solve the problem that damping has not attracted more attention from people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

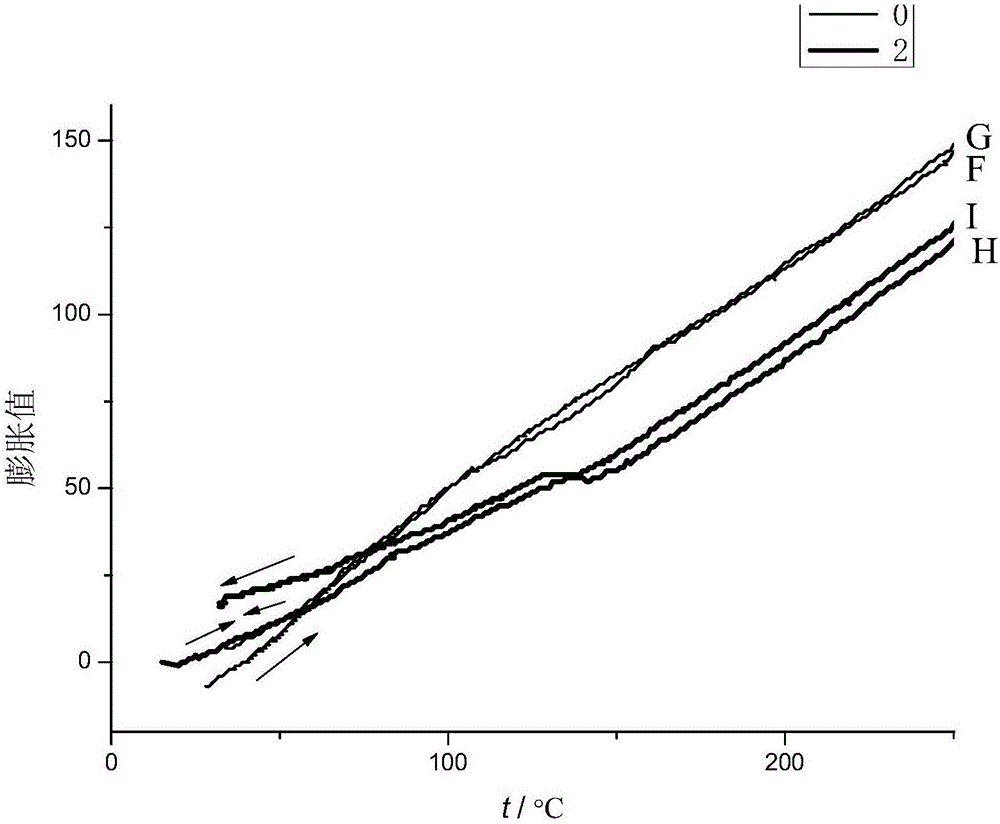

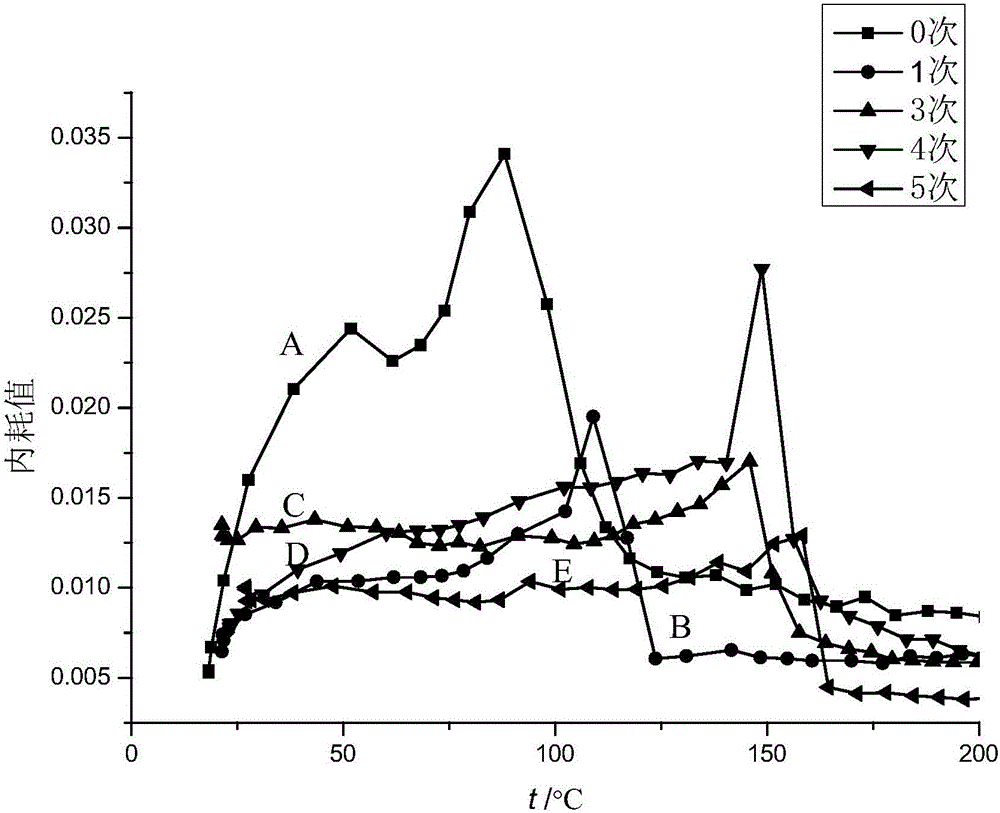

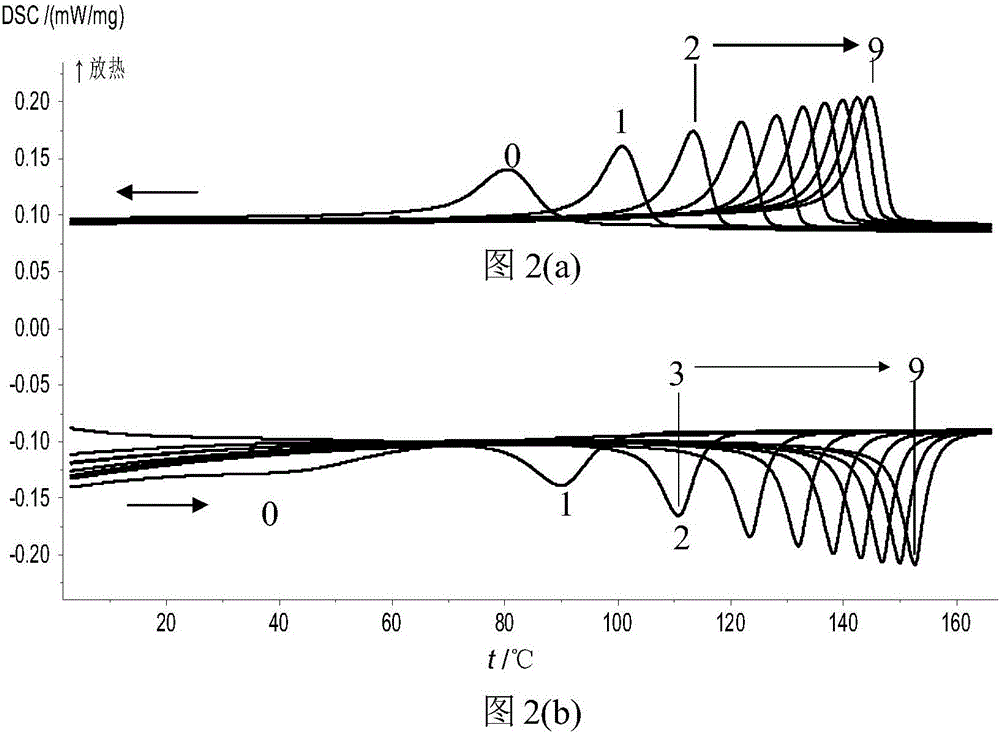

[0024] In order to more clearly illustrate the embodiments of the present invention or the technical solutions in the prior art, the specific implementation manners of the present invention will be described below with reference to the accompanying drawings. Obviously, the accompanying drawings in the following description are only some embodiments of the present invention, and those skilled in the art can obtain other accompanying drawings based on these drawings and obtain other implementations.

[0025] The present invention is described in detail below taking Mn-Cu-Al atomic percentage as 82.2:15.8:2 as an example:

[0026] In the preparation process, first, according to the atomic percentage of Mn-Cu-Al (82.2:15.8:2), it is converted into the corresponding mass percentage, and the corresponding electrolytic Mn sheet (purity>99.9%), pure Cu block (purity>99.9%) and pure Al block (purity>99.9%).

[0027] Afterwards, using a vacuum non-consumable electric arc furnace, usin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap