Reeding frame

A technology of movable rods and fixed seats, which is applied in the field of reed racks, can solve the problems of large space, affecting the passability and cleanliness of the site, and achieve the effect of convenient use, simple structure and clean site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

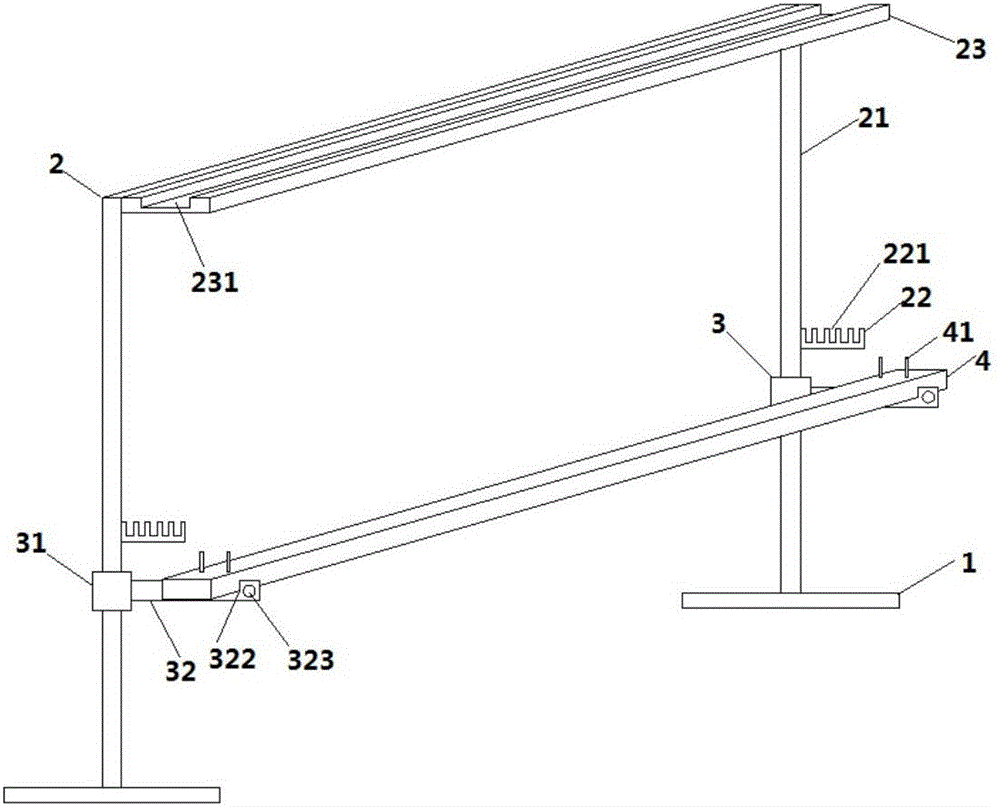

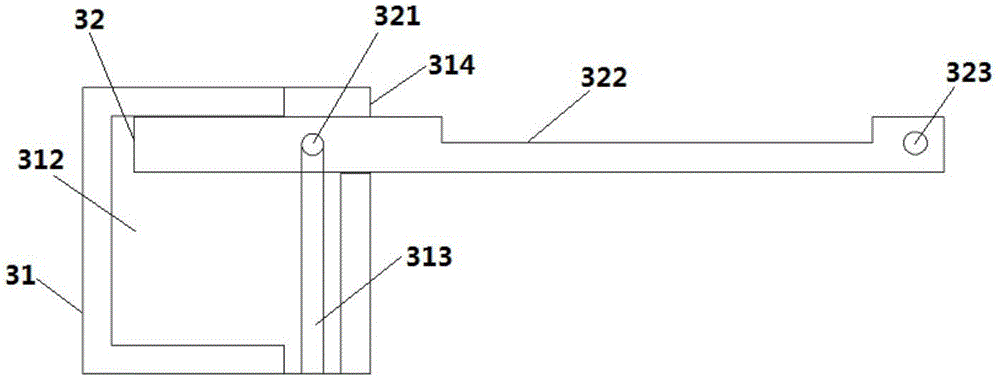

[0014] A reed rack, such as figure 1 As shown, it includes a leg 1 and a bracket 2. The uprights 21 on both sides of the bracket 2 are provided with a pole 22 perpendicular to the bracket 2, and the pole 22 is provided with a limiting groove 221 for clamping the heddle. The column 21 below the pole 22 is provided with a support bar 3 in the same direction as the pole 22, and a horizontal plate 4 is horizontally mounted on the support bar 3, and the horizontal plate 4 is provided with a limit pile 41, and the support bar 3 is fixed The seat 31 and the movable rod 32 are formed, the fixed seat 31 is fixed on the column 21, and the fixed seat 31 is provided with a slot 311 that runs through the fixed seat 31 in the vertical direction, and the fixed seat 31 is provided with the slot 311 Connected flat cavity 312, the two side walls of the slot 311 are provided with vertical grooves 313, the bottom of the groove 313 is in a through state, the movable rod 32 is a strip rod, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com