Air energy storage efficient energy recovery mechanism

An air energy storage and air compressor technology, applied in the field of energy storage, can solve the problems of low conversion rate, low recovery and utilization rate of excess electric energy, waste of electric energy, etc., and achieve high recovery and reuse rate, which is conducive to normal use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

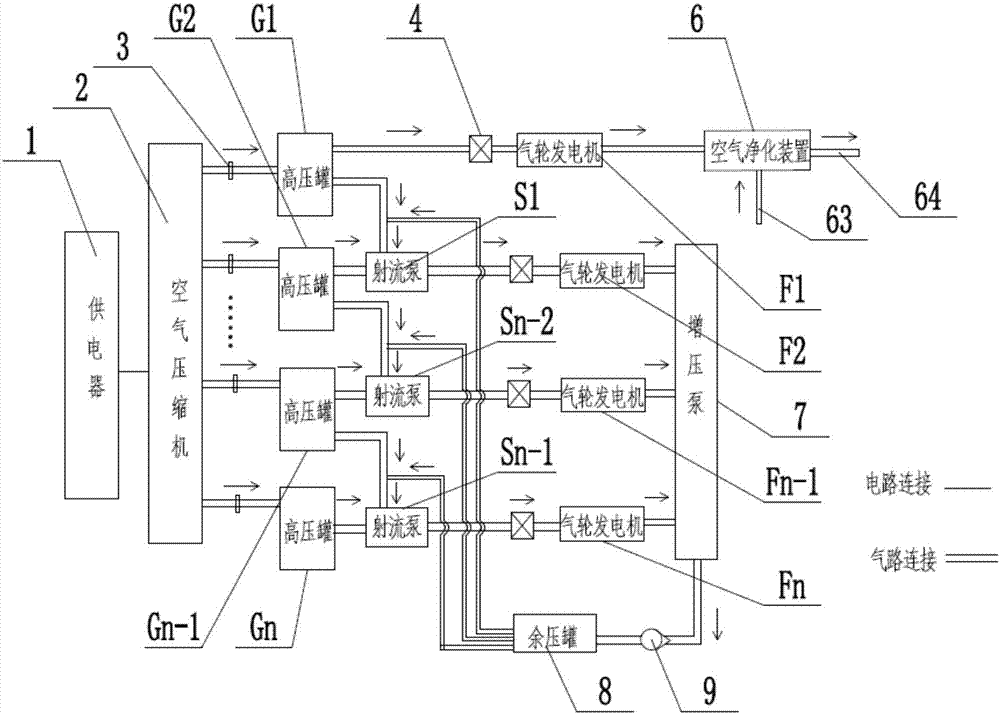

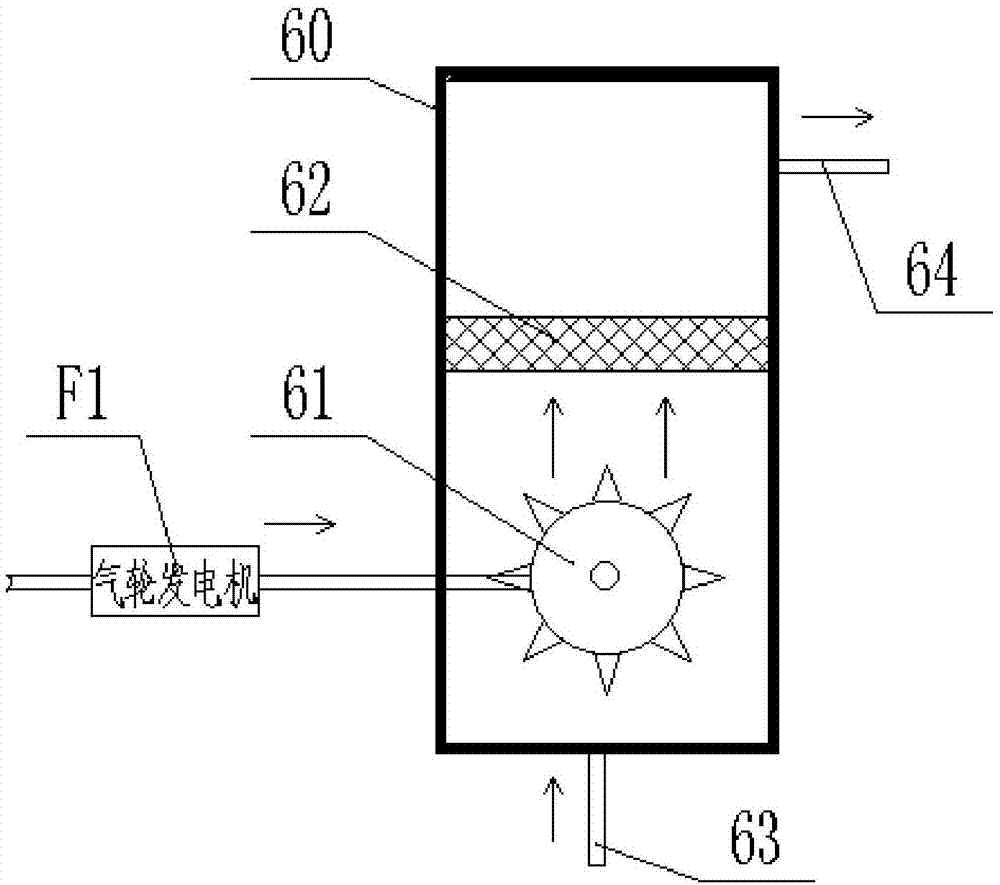

[0019] Such as figure 1 , 2 As shown, an air energy storage and high-efficiency energy recovery mechanism includes a power supply 1 that can provide green electric energy periodically, an air compressor 2, n high-pressure tanks (G1, G2...Gn-1, Gn), n-1 A jet pump (S1...Sn-2, Sn-1), n turbine generators (F1, F2...Fn-1, Fn), an air purification device 6, a booster pump 7 and a residual pressure tank 8, Where n is a positive integer greater than 1.

[0020] The output terminal of the power supply 1 is connected to the input terminal circuit of the air compressor 2. The power supply 1 increases the electric energy for the air compressor 2 and drives it to work. When the air compressor 2 works, the low-pressure gas will be Convert into high-pressure gas, this gas can specifically be air, there are n output ends on the described air compressor 2, and each outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com