A compressor reliability detection method and device

A detection method and compressor technology, which is applied in the field of compressors, can solve problems such as poor reliability detection schemes, and achieve the effects of rapid judgment response, accurate judgment, and detailed data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

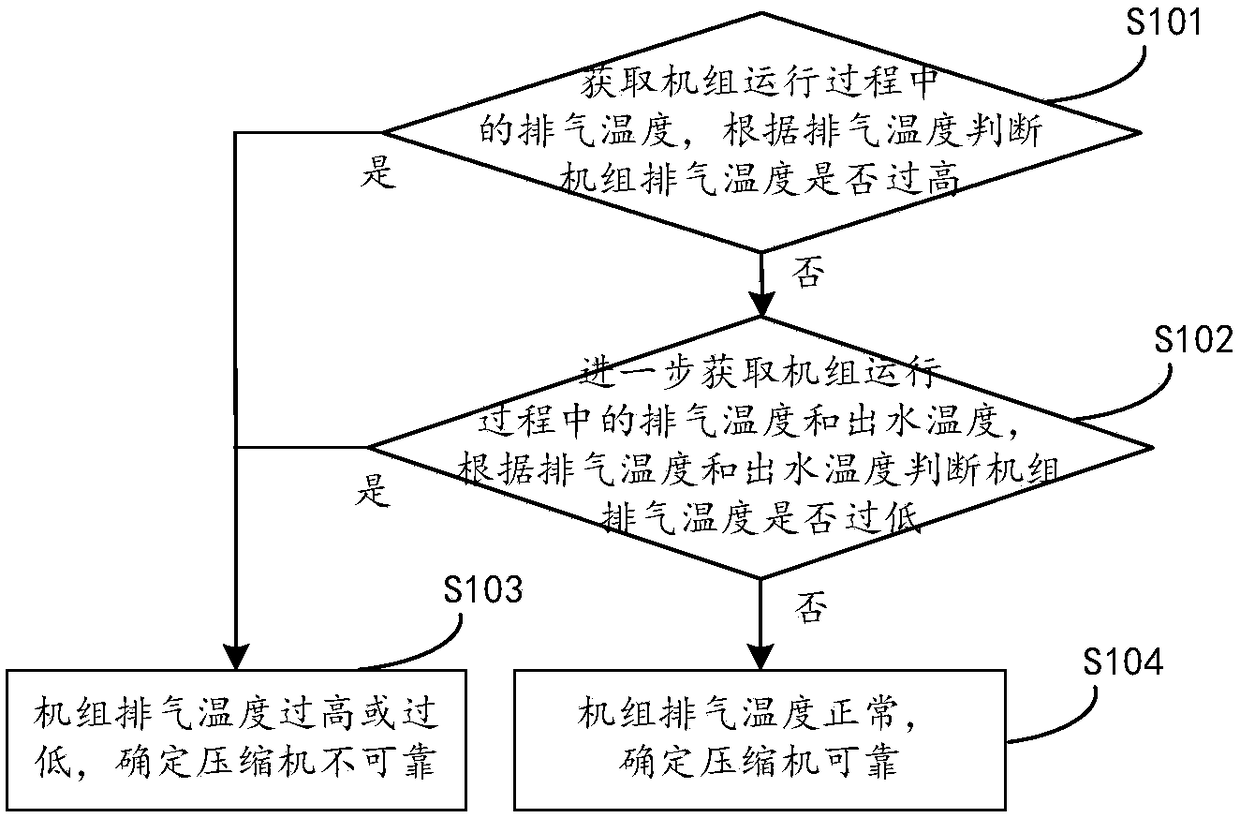

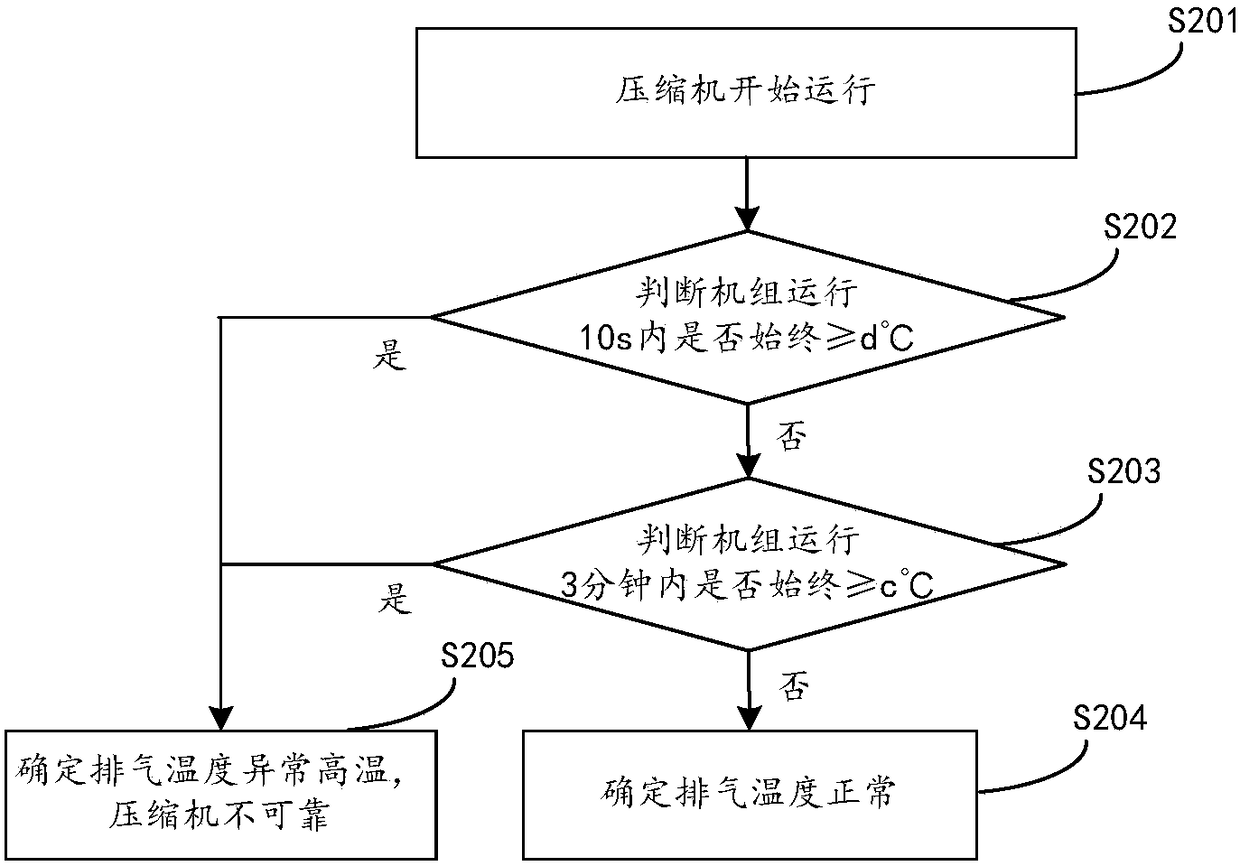

[0026] figure 1 is a flowchart of a method for detecting reliability of a compressor according to an embodiment of the present invention, such as figure 1 As shown, the method includes the following steps (step S101-step S104):

[0027] Step S101 , acquire the exhaust temperature of the unit during operation; judge whether the exhaust temperature of the unit is too high according to the exhaust temperature; if yes, execute step S103 ; if not, execute step S102 .

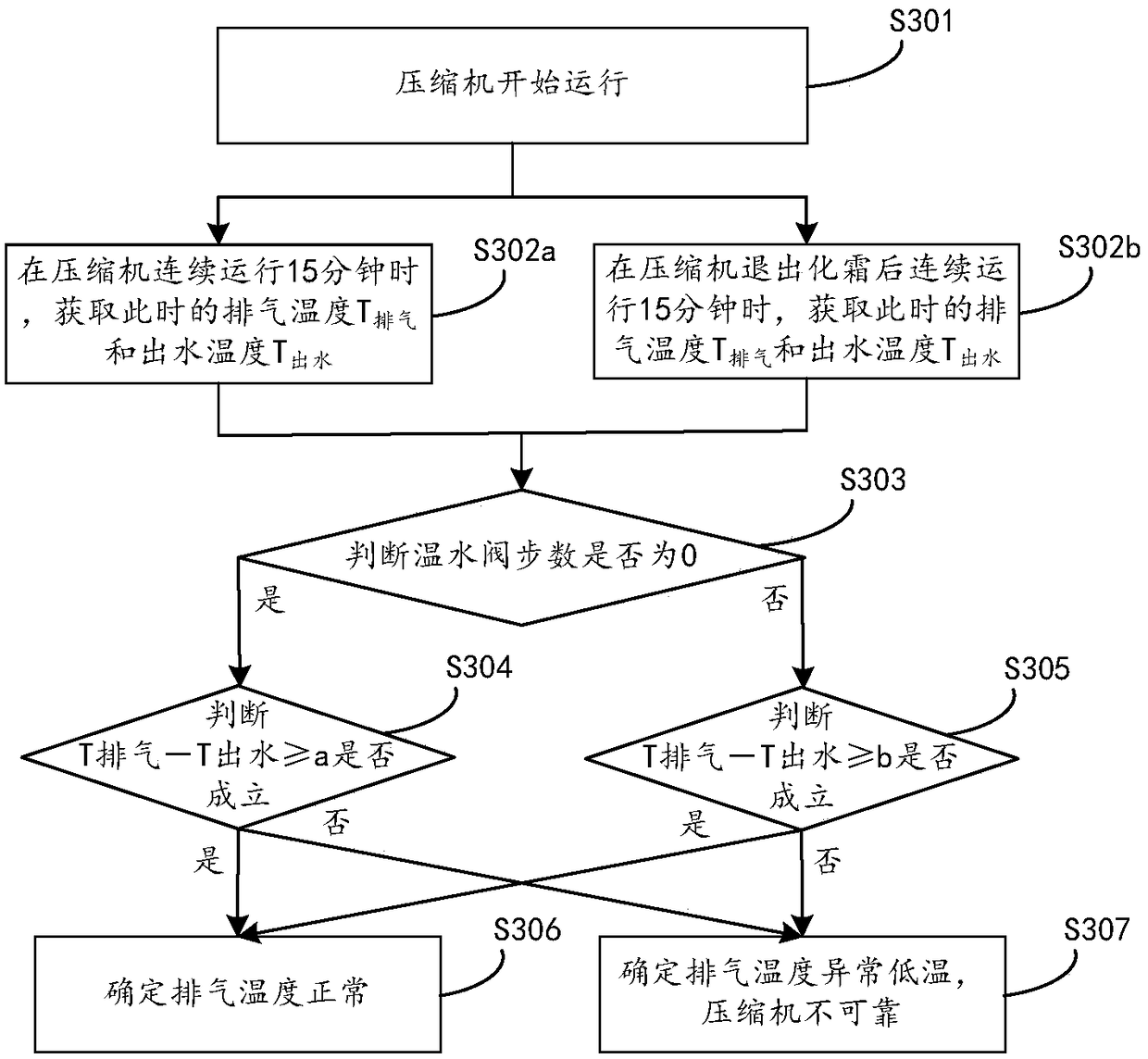

[0028] Step S102, further obtain the exhaust temperature and outlet water temperature during the operation of the unit; judge whether the exhaust temperature of the unit is too low according to the exhaust temperature and outlet water temperature; if yes, execute step S103; if not, execute step S104.

[0029] Step S103, the exhaust temperature of the unit is too high or too low, and it is determined that the compressor is unreliable.

[0030] Step S104, the discharge temperature of the unit is normal, and it is det...

Embodiment 2

[0061] corresponds to figure 1 In the compressor reliability detection method introduced, this embodiment provides a compressor reliability detection device, such as Figure 5 The structural block diagram of the compressor reliability detection device shown, the device includes:

[0062] The over-temperature detection module 10 is used to obtain the exhaust temperature during the operation of the unit; judge whether the exhaust temperature of the unit is too high according to the exhaust temperature; if so, determine that the compressor is unreliable;

[0063] The over-low temperature detection module 20 is used to further obtain the exhaust gas temperature and the outlet water temperature during the operation of the unit when the detection result of the above-mentioned over-temperature over-temperature detection module 10 is negative; Check whether the air temperature is too low; if yes, determine that the compressor is unreliable; if not, determine that the compressor is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com