Locking device and application thereof

A locking device and locking seat technology, applied in the connection of rods, connecting components, stone processing tools, etc., can solve the problems of easy damage to the saw blade body, low accuracy, poor flatness of the plate, etc., to improve stability and reliability. Accuracy, ensure stable operation, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present case will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

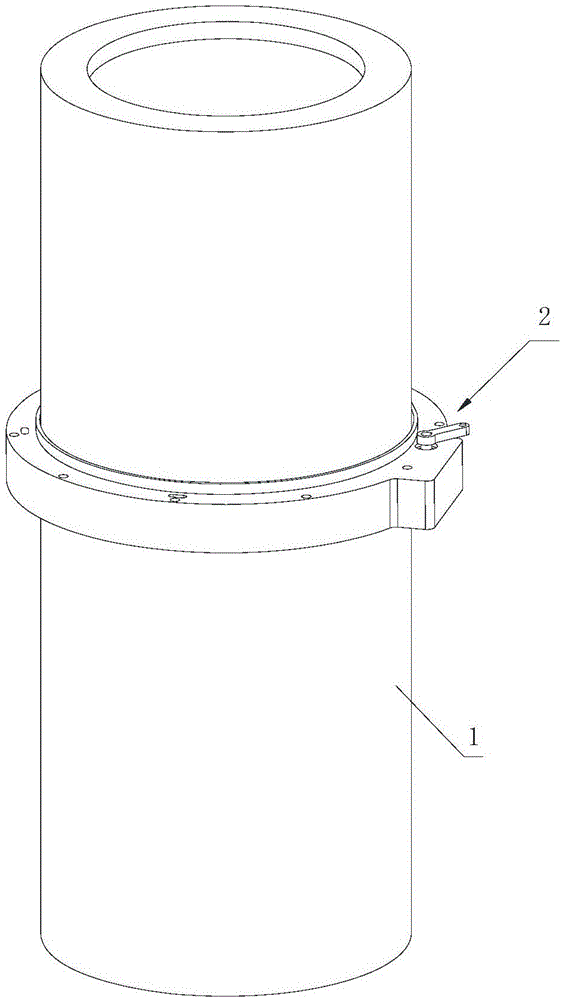

[0045] This case concerns a locking device, suitably installed at the corresponding movable part of the relevant equipment, such as figure 1 A schematic diagram is given, which is installed on the lifting column 1.

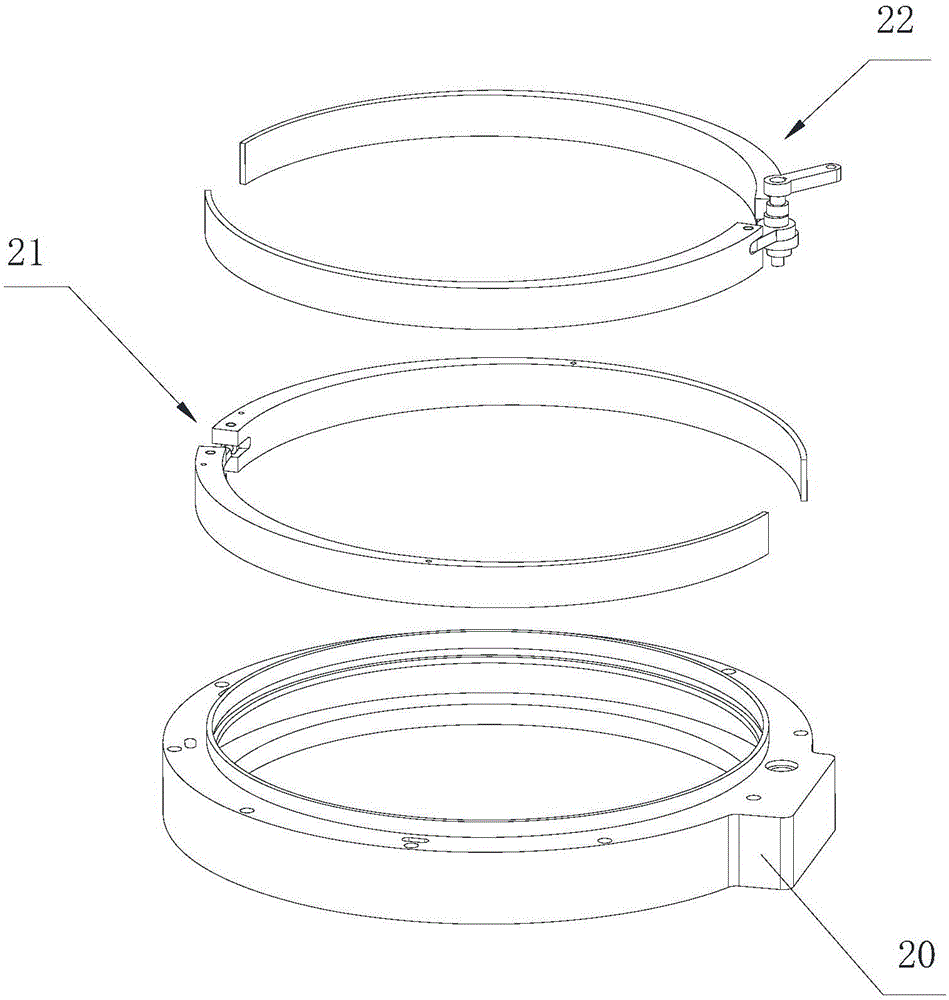

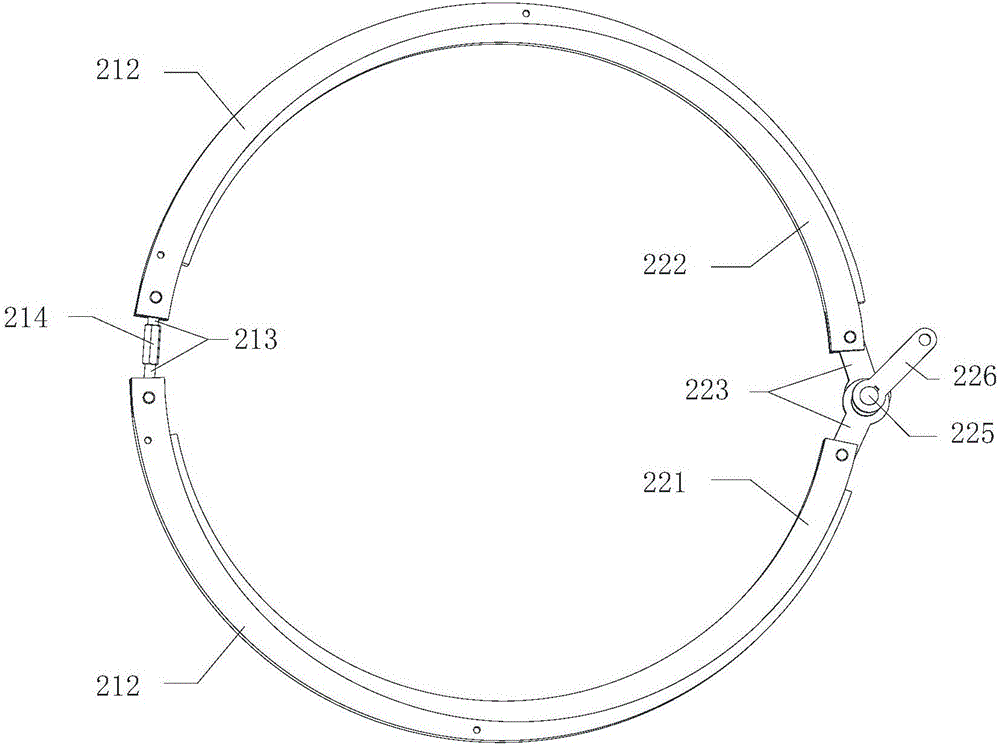

[0046] Such as Figure 2-11 As shown, the locking device 2 includes a locking seat 20 , an outer locking brake 21 and an inner locking brake 22 . The outer holding brake 21 is assembled in the locking seat 20, and the inner holding brake 22 is assembled in the inner side of the outer holding brake 21, and the two are matched and arranged. Specifically, the relevant parts have fixed parts and movable parts that are properly assembled with each other, such as a crossbeam as a fixed part, and a lifting column 1 that runs through the crossbeam as a movable part for lifting activities, and the locking seat 20 is fixedly installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com