A compressed air rotary device for a frame twisting machine

A technology of compressed air and rotary devices, applied in mechanical equipment, engine components, engine seals, etc., can solve problems such as reduced service life of equipment, air leakage, shortened service life of copper-based graphite seal rings and rubber O-rings, etc. , to achieve the effect of reducing energy loss, reducing manufacturing costs and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

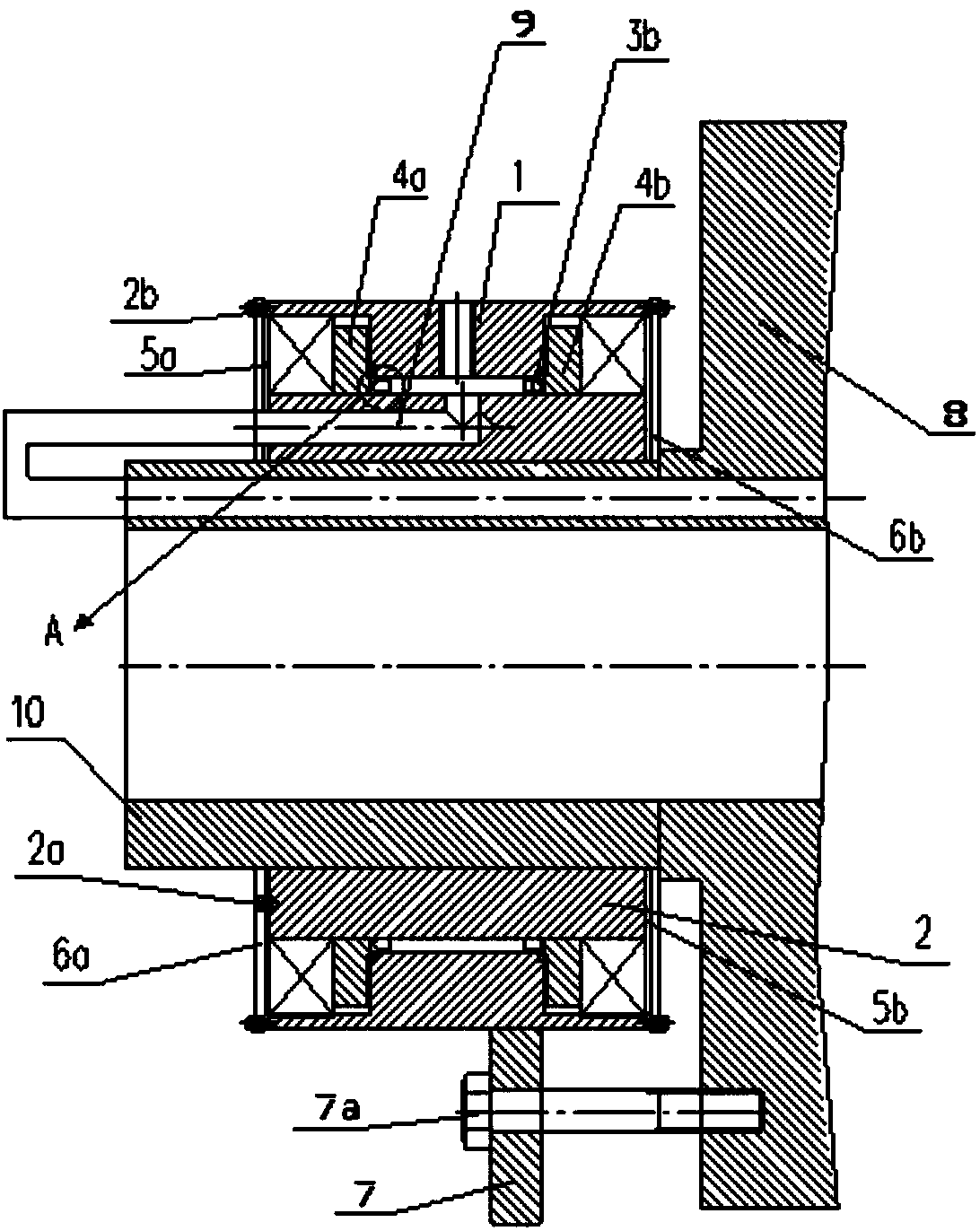

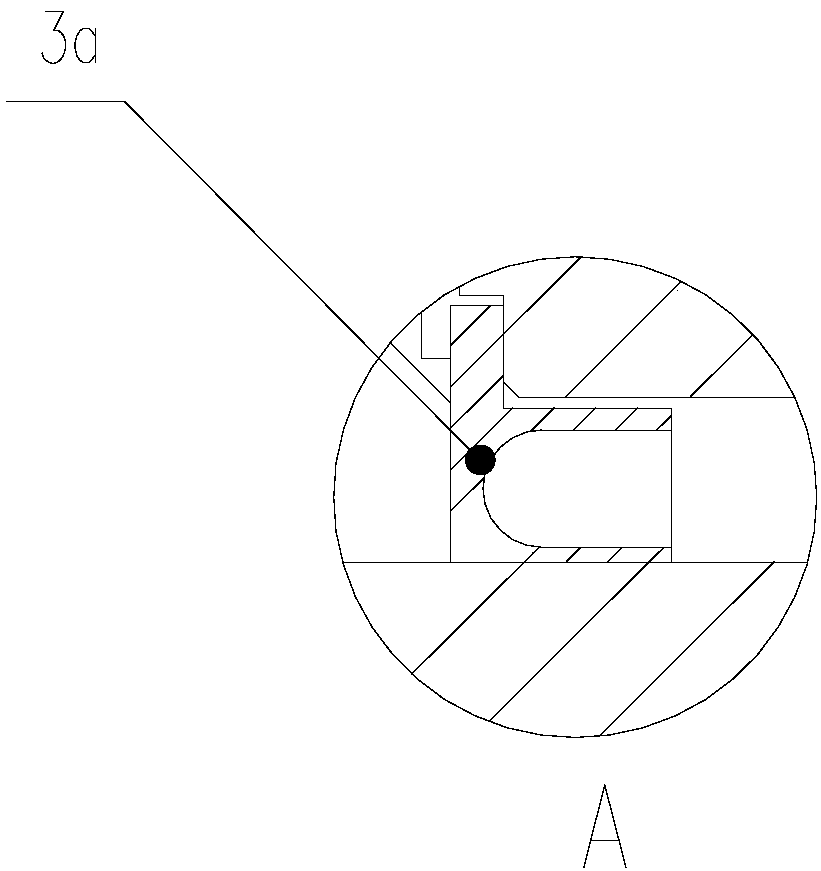

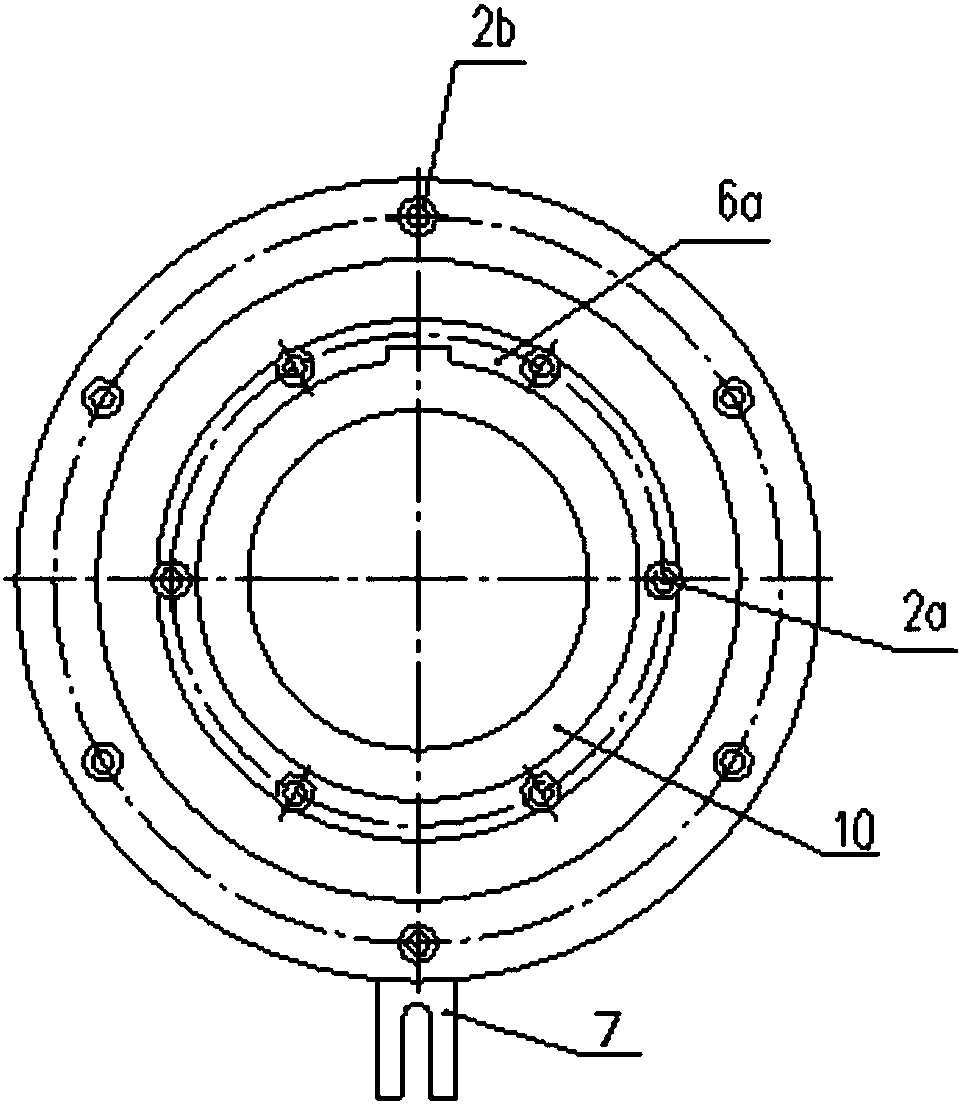

[0019] Such as Figures 1 to 3 As shown, the compressed air rotary device of the frame twisting machine is installed on the main shaft 10 of the frame twisting machine, including a rotary outer ring 1, a rotary inner ring 2, a U-shaped universal plug seal 3, a sealing ring 4, and an inner ring The end cover pressure plate 5, the outer ring end cover pressure plate 6 and the support seat 7, the inner part of the rotary inner ring 2 is provided with a keyway, which is connected with the main shaft 10 of the frame winch machine through a flat key and rotates together, and the lower part of the rotary outer ring 1 is provided with a support seat 7, The support seat 7 is fixedly connected with the baffle plate 8 through the third bolt 7a, the rotary outer ring 1 and the rotary inner ring 2 are provided with an air passage 9, and the rotary outer ring 1 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com