Driven sealing floating ball blow-down valve

A blowdown valve and floating ball technology, applied in the direction of safety valve, balance valve, valve device, etc., can solve the problems that mechanical blowdown valve can no longer be used, and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

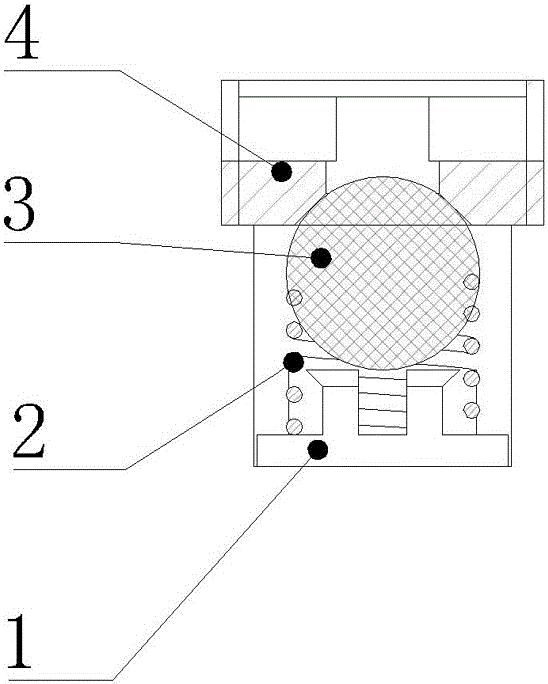

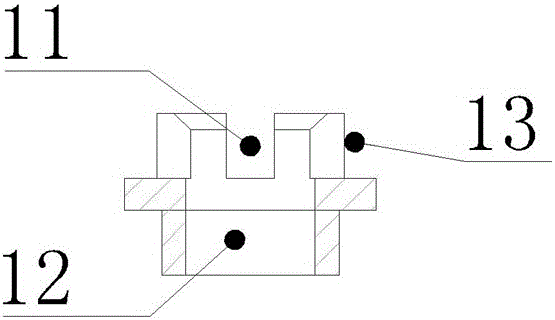

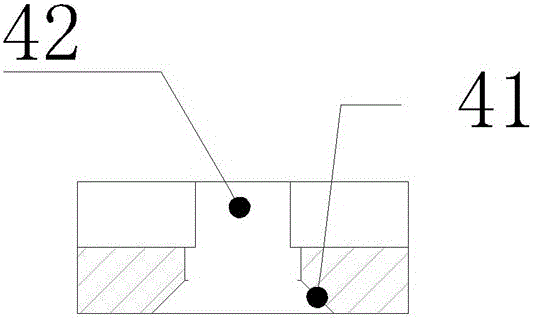

[0012] Such as Figure 1 to Figure 3 As shown, in the present invention, the present invention includes a sewage guide sleeve 1, a spring 2, a sealing float 3, and a sewage cover 4. The sewage guide sleeve 1 is provided with a spring mounting surface 13, and the spring 2 is arranged on the spring. On the installation surface 13, the sealing float 3 is arranged between the sewage guide sleeve 1 and the sewage cover 4, and the sewage guide sleeve 1 is also provided with a sewage guide sleeve guide hole 11 and a sewage guide sleeve drain hole 12. The drain cover 4 is provided with a drain cover sealing surface 41 and a drain cover drain hole 42.

[0013] Principle: When working, when compressed air enters the filter through the filter inlet on the multi-function filter tube head, it is processed by the air-water separation device first, and a large amount of liquid water falls on the slope at the bottom of the tube body and flows into the slope. The bottom of the sewage outlet; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com