Novel heating system

A heating system and a new type of technology, applied in the field of heating, can solve the problems of complex structure and inability to automatically adjust the temperature, and achieve the effects of increasing the operating cycle, simple and practical structure, and accurate adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

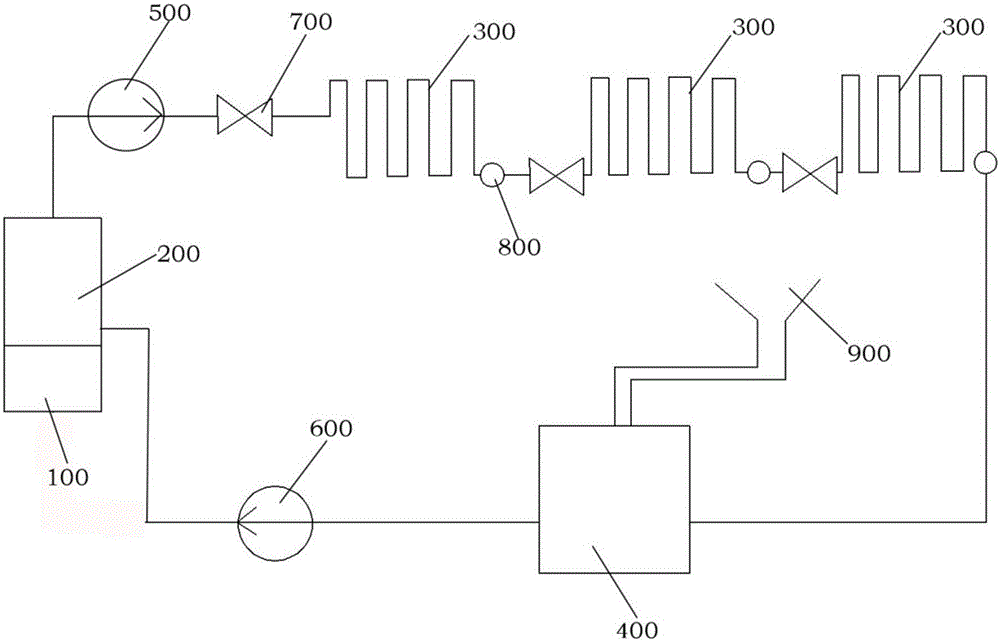

[0023] Such as figure 1A new type of heating system shown includes a combustion chamber 100, a heating chamber 200, a plurality of radiators 300, a water storage tank 400, an inlet water pump 500 and a return water pump 600; the combustion chamber 100 is arranged at the bottom of the heating chamber 200, through The giant magnetic fuel injection pump burns fuel to heat the water in the heating chamber 200, and the hot water generated is driven by the water inlet pump 500 into multiple radiators 300 connected in series, and the low-temperature water after passing through the radiators 300 enters the water storage tank 400. Then return the bottom of the heating chamber 200 by the return pump 600; the inlet pipe of each radiator 300 is provided with a flow control valve 700, and the outlet pipe of each radiator 300 is provided with a temperature sensor 800, and the controller according to each The temperature feedback value of each outlet pipe is used to adjust the opening degree...

Embodiment 2

[0031] Such as figure 1 A new type of heating system shown includes a combustion chamber 100, a heating chamber 200, a plurality of radiators 300, a water storage tank 400, an inlet water pump 500 and a return water pump 600; the combustion chamber 100 is arranged at the bottom of the heating chamber 200, through The giant magnetic fuel injection pump burns fuel to heat the water in the heating chamber 200, and the hot water generated is driven by the water inlet pump 500 into multiple radiators 300 connected in series, and the low-temperature water after passing through the radiators 300 enters the water storage tank 400. Then return the bottom of the heating chamber 200 by the return pump 600; the inlet pipe of each radiator 300 is provided with a flow control valve 700, and the outlet pipe of each radiator 300 is provided with a temperature sensor 800, and the controller according to each The temperature feedback value of each outlet pipe is used to adjust the opening degre...

Embodiment 3

[0039] Such as figure 1 A new type of heating system shown includes a combustion chamber 100, a heating chamber 200, a plurality of radiators 300, a water storage tank 400, an inlet water pump 500 and a return water pump 600; the combustion chamber 100 is arranged at the bottom of the heating chamber 200, through The giant magnetic fuel injection pump burns fuel to heat the water in the heating chamber 200, and the hot water generated is driven by the water inlet pump 500 into multiple radiators 300 connected in series, and the low-temperature water after passing through the radiators 300 enters the water storage tank 400. Then return the bottom of the heating chamber 200 by the return pump 600; the inlet pipe of each radiator 300 is provided with a flow control valve 700, and the outlet pipe of each radiator 300 is provided with a temperature sensor 800, and the controller according to each The temperature feedback value of each outlet pipe is used to adjust the opening degre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com