Comprehensive recovery and utilization system of exhaust gas and waste heat of sintering ring cooler

A sintering ring cooler and ring cooler technology, which is applied in the energy saving field of the steel industry, can solve the problems such as the deterioration of the operating environment of the ring cooler, the deformation of the ring cooler frame, and the waste of energy, so as to achieve scientific energy use and improve effective utilization. efficiency, and the effect of increasing power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

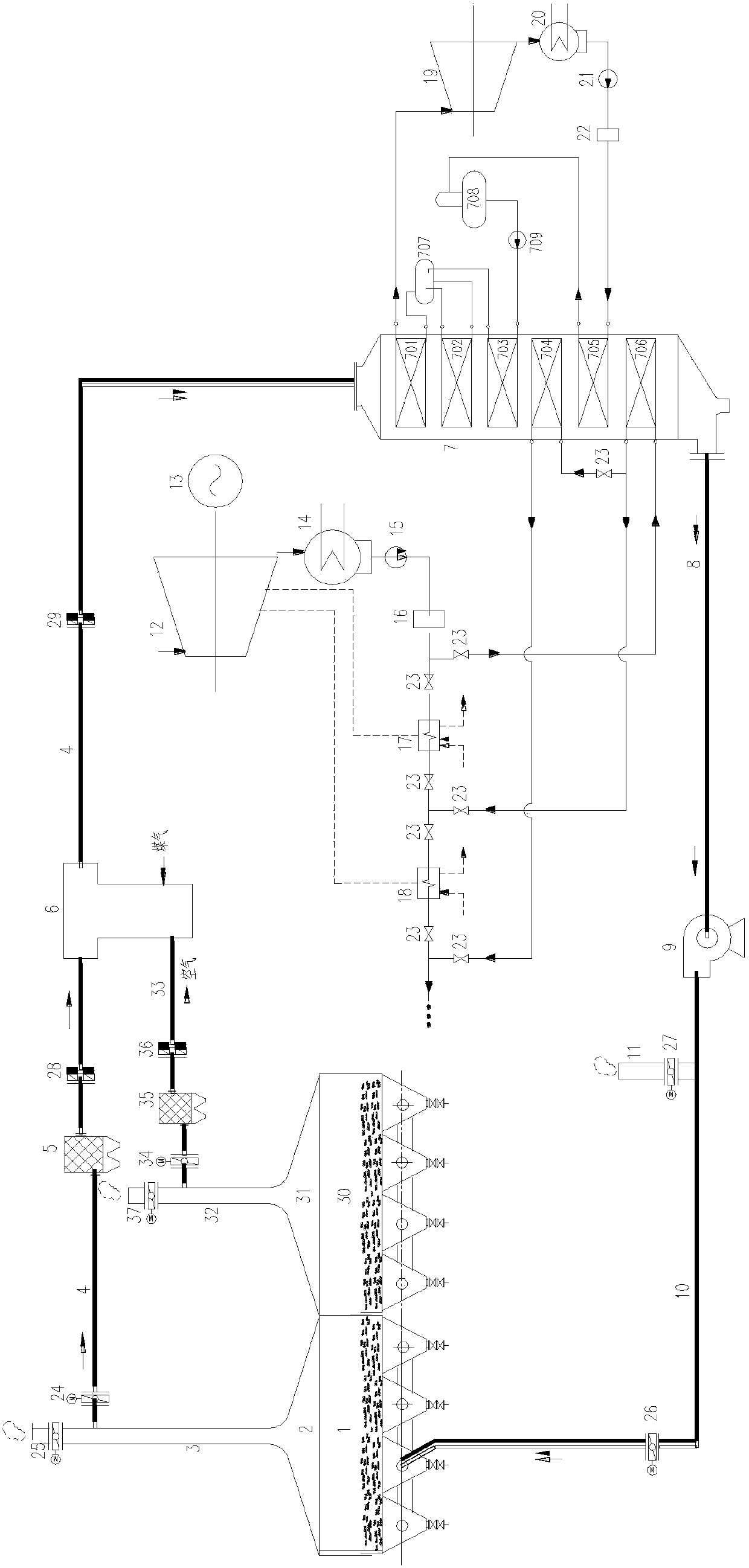

[0027] Such as figure 1 As shown, the exhaust gas waste heat comprehensive recovery and utilization system of the sintering ring cooler includes a flue gas circulation system; The high-temperature chimney 3 above, the conventional air intake pipe 4 and the waste heat boiler 7 communicating with the high-temperature chimney 3; wherein, the flue gas inlet and the flue gas outlet of the waste heat boiler 7 are respectively connected to the conventional air intake pipe 4 and the ring cooler. The air duct 10 is connected, and the flue of the waste heat boiler 7 is sequentially provided with a superheater 701, an evaporator 702, a high-pressure section economizer 703, a second condensate heater 704, and a low-pressure section economizer 705. and the first condensate heater 706, a steam drum 707 is arranged outside the flue of the waste heat boiler 7; a deoxidizer is arranged in sequence along the water flow direction between the water outlet of the low-pressure section economizer 70...

Embodiment 2

[0040] On the basis of the above-mentioned embodiments, a high-temperature dust collector 5 and a post-combustion furnace 6 are sequentially arranged on the conventional air intake duct 4 along the direction of flue gas flow.

[0041] The high-temperature dust collector 5 is used to remove the particles brought in from the annular cooler in the conventional air intake pipe 4; the post-combustion furnace 6 is located between the dust collector and the waste heat boiler 7 to adjust the parameters of the flue gas entering the waste heat boiler 7;

[0042] In this embodiment, through the setting of the post-combustion furnace 6, the flue gas condition at the inlet of the waste heat boiler 7 is stabilized, the steam parameters at the outlet of the waste heat boiler 7 are stabilized, and the safe and stable operation of the steam turbine 19 of the waste heat utilization unit is guaranteed.

[0043] This embodiment stabilizes the flue gas conditions of the exhaust gas waste heat recov...

Embodiment 3

[0045] On the basis of the above-mentioned embodiments, the low-temperature unconventional waste heat recovery section 30 of the annular cooler in this embodiment is provided with a gas collection hood 31, and the gas collection hood 31 is provided with a low-temperature chimney 32; the low-temperature chimney 32 passes through The low-temperature air intake pipe 33 communicates with the air inlet of the supplementary combustion furnace 6 , and the gas inlet of the supplementary combustion furnace 6 communicates with the gas pipeline; the low-temperature air intake duct 33 is provided with a low-temperature dust collector 35 .

[0046] The outlet of the low-temperature chimney 32 is provided with a fifth smoke valve 37 , and the inlet of the low-temperature air intake pipe 33 is provided with a sixth smoke valve 34 .

[0047] The exhaust gas waste heat comprehensive recovery and utilization system of the sintering ring cooler of the present invention collects the flue gas (the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com