Sintering Ring Refrigerator Exhaust Gas Waste Heat Recovery and Utilization System

A sintered ring cooler and waste heat recovery technology, applied in waste heat treatment, steam generation method using heat carrier, climate sustainability, etc., can solve problems such as deterioration of the operating environment of the ring cooler, unfavorable use of waste heat, and energy waste. Achieve the effects of ensuring safe and stable operation, reducing the amount of regenerative steam extraction, and improving operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

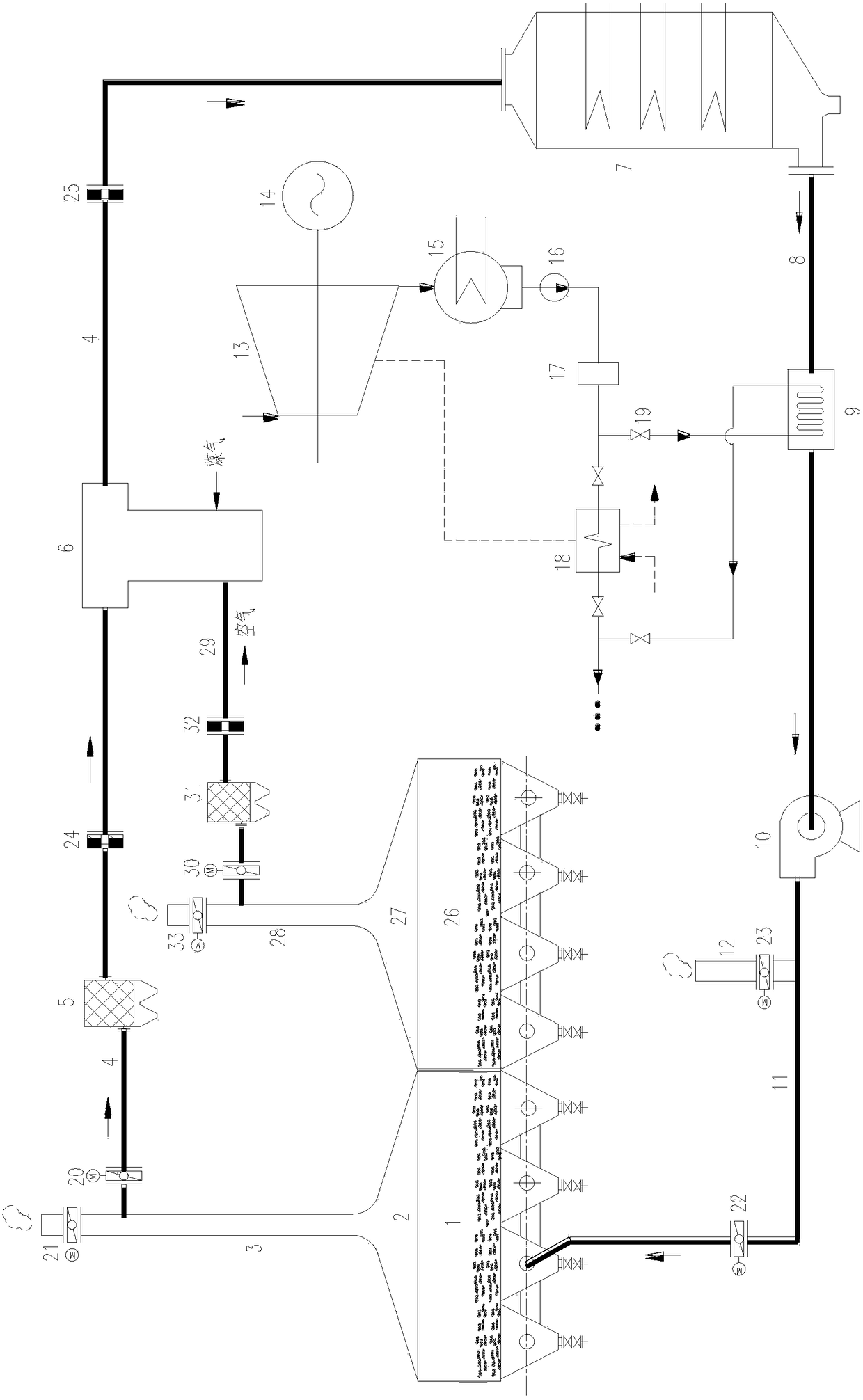

[0028] Such as figure 1 As shown, the exhaust gas waste heat recovery and utilization system of the sintering ring cooler in this embodiment includes a conventional flue gas circulation system;

[0029] The flue gas circulation system includes a conventional waste heat recovery section 1 of the annular cooler, a smoke collection hood 2 arranged above the conventional waste heat recovery section 1 of the annular cooler, a high-temperature chimney 3 arranged on the smoke collection hood 2 and a waste heat recovery Waste heat boiler 7; the high-temperature chimney 3 and the flue gas inlet of the waste heat boiler 7 are connected through a conventional air intake pipe 4, the flue gas outlet of the waste heat boiler 7 is connected with a smoke exhaust pipe 8, and the conventional waste heat of the annular cooler The air return port of the recovery section 1 is connected with a return air duct 11, and the exhaust duct 8 communicates with the return air duct 11; the exhaust duct 8 of...

Embodiment 2

[0052] On the basis of the above embodiments, the conventional air intake duct 4 is provided with a first dust remover 5, the first dust remover 5 and the afterburning furnace 6 are sequentially arranged along the flow direction of the flue gas, and the low temperature chimney 28 communicates with the air inlet of the post-combustion furnace 6 through a low-temperature air intake pipe 29, and a second dust collector 31 is arranged on the low-temperature air intake pipe 29.

[0053] Dust collectors are arranged on the low-temperature air intake pipeline 29 and the conventional air intake pipeline 4 to remove the particulate matter carried out in the flue gas, which can reduce the deposition of particulate matter in the pipeline and avoid pipeline blockage due to excessive particulate matter deposition. At the same time, the particulate matter When running in the pipeline, the pipeline will also be worn, and the removal of particulate matter can reduce the wear on the pipeline an...

Embodiment 3

[0055] On the basis of the above embodiments, the inlet and outlet of the flue gas-condensed water heat exchanger 9 and the inlet and outlet of the low-pressure heater group 18 are respectively provided with control valves 19 .

[0056] The exhaust gas waste heat recovery and utilization system of the sintering ring refrigerator in this embodiment can realize the adjustment of the ratio of the heat provided by the low pressure heater group 18 and the flue gas-condensed water heat exchanger 9 to the generator set by adjusting the opening degree of the control valve 19 The switching operation of the low-pressure heater group 18 and the flue gas-condensed water heat exchanger 9 is realized through the switch of the valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com