Heating structure and heating method of boiler based on partitioned flue and multistage air preheating

A technology for separating the flue and air preheating, which is applied to steam boilers, combustion methods, lighting and heating equipment, etc., can solve the problems that the heat released by the flue gas cannot be effectively used, the temperature utilization space is limited, and there is no consideration for restrictions, etc., to achieve reduction The effect of reheating and extracting steam, reducing coal consumption and increasing air temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

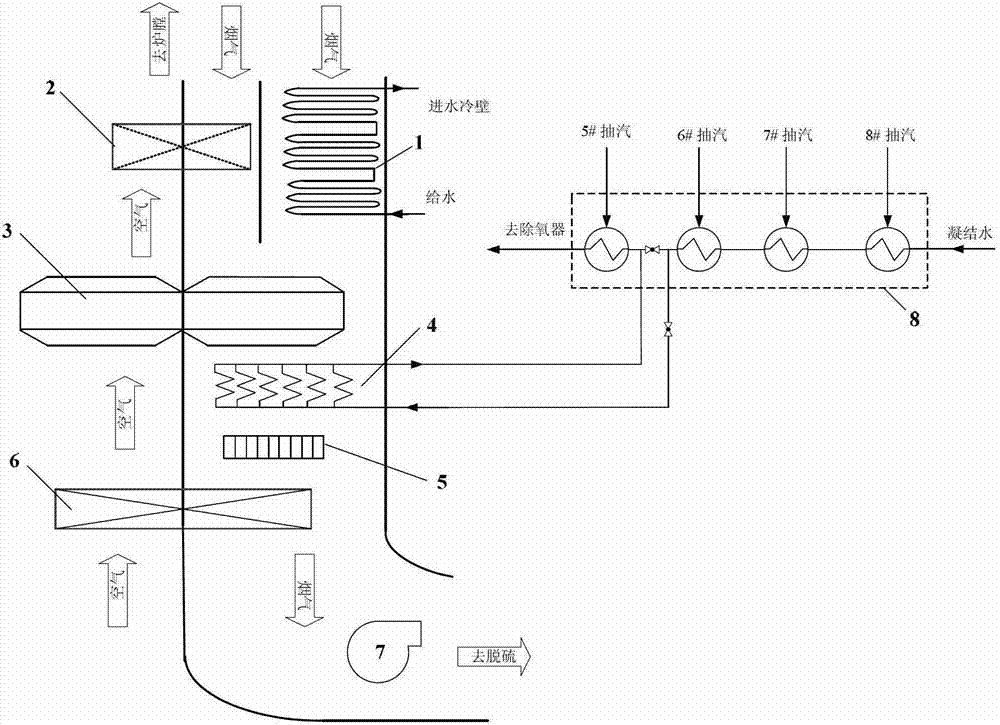

[0021] The present invention provides a boiler heating structure and heating method based on separated flue and multi-stage air preheating, which will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0022] figure 1 It is a schematic diagram of the structure of the present invention. In the front section of the flue at the tail of the boiler, a partition plate is used to divide the flue into two paths. Economizer 1 and high-temperature air preheater 2 are respectively arranged on both sides of the partition plate. The main air preheater 3, flue gas-condensed water heat exchanger 4, dust collector 5, front air preheater 6, and blower 7 are arranged in sequence in the tunnel.

[0023] This system uses the waste heat of the flue gas to heat the hot air entering the furnace and part of the low-pressure condensed water. The principle is as follows; the tail flue is divided into two parts: the separated flue and the main flue. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com