Fuel coal decarburization and waste heat utilization power generation system integrating supercritical carbon dioxide and heat pump

A power generation system and power generation sub-system technology, which is applied in the direction of machines/engines, chemical instruments and methods, steam engine devices, etc., can solve problems such as large heat consumption, impact on the safety of low-pressure cylinders, and reduction of effective work output of the system to achieve reduction The effect of regenerative steam extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

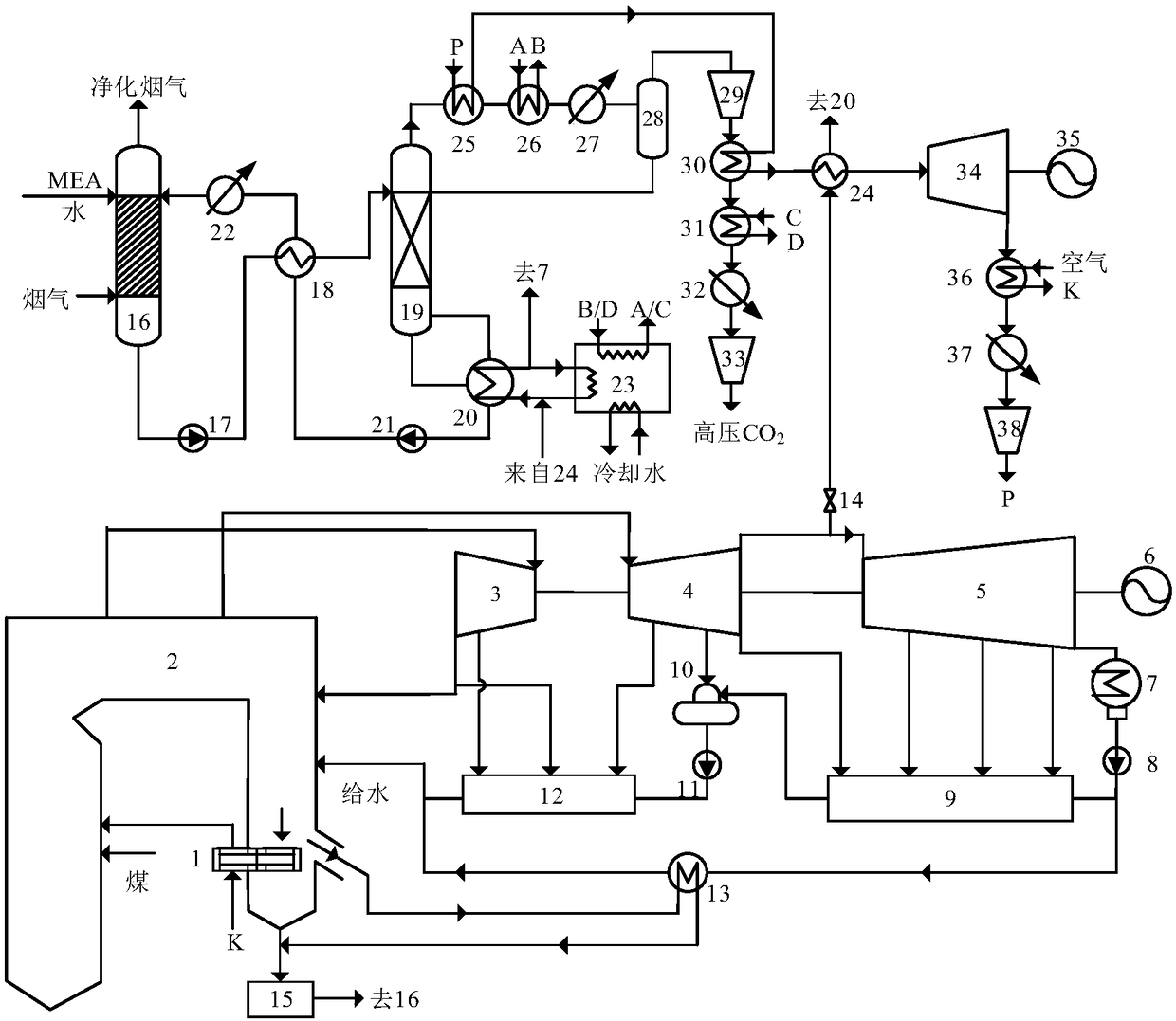

[0014] The present invention provides integrated supercritical CO 2 Coal-fired decarbonization and waste heat utilization power generation system with heat pump, the present invention will be further described below in conjunction with the accompanying drawings.

[0015] Such as figure 1 As shown, the system includes coal-fired power generation sub-system, decarbonization sub-system and CO 2 Cyclic power generation subsystem; in the figure, the main steam at the outlet of boiler 2 is connected to the steam inlets of high-pressure cylinder 3 and medium-pressure cylinder 4, and high-pressure cylinder 3, medium-pressure cylinder 4, low-pressure cylinder 5, and 1# generator 6 are connected in series in sequence; The exhaust steam of cylinder 5 is connected to the inlet of condenser 7, and condenser 7, condensate pump 8, low-pressure heater group 9, deaerator 10, feed water pump 11, and high-pressure heater group 12 are connected in series in sequence; low-pressure heater group 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com