Air cooling type tube bundle of heat exchanger

A heat exchanger, air-cooled technology, applied in the direction of heat exchange equipment, heat exchanger type, indirect heat exchanger, etc., can solve the problems of heavy welding workload, heavy labor workload, long construction period, etc., to reduce manufacturing and The effect of using maintenance cost, less work difficulty, and less material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

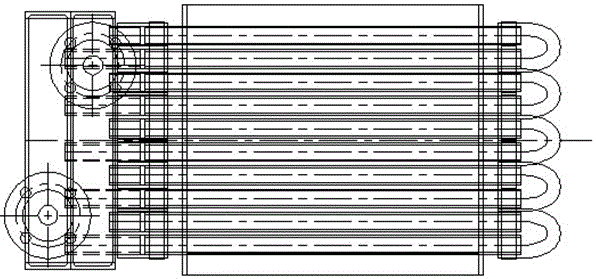

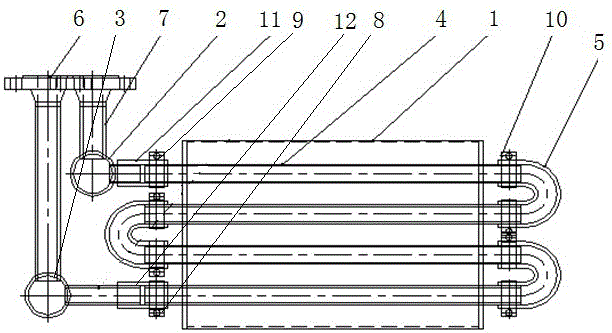

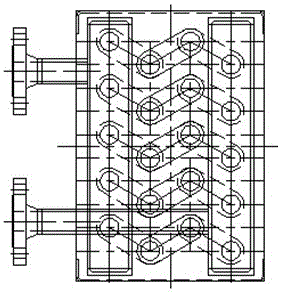

[0015] The present invention will be described below in conjunction with the accompanying drawings.

[0016] As shown in the accompanying drawings, an air-cooled heat exchanger tube bundle includes a supporting steel plate 1, an inlet header 2, an outlet header 3, a finned tube 4, a U-shaped tube 5, a flange 6 and a connecting tube 7, and its characteristics The outlet fixing clip 8, the inlet fixing clip 9, the fixing clip 10, the first straight pipe connection soft sleeve 11 and the second straight pipe connection soft sleeve 12 are provided, and the U-shaped pipe adopts a U-shaped soft sleeve, which is relatively Adjacent finned tubes are supported and connected by supporting steel plates, and the adjacent finned tubes 4 are connected end-to-end through U-shaped hoses 5, and the U-shaped hoses are connected through the fixing clip 10 and the fixing bolts and nuts on the fixing clip 10. It is fixedly connected with the finned tube, the inlet of the finned tube 4 at the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com