Die-cast lamp shell leak detection clamping tool

A technology for clamping tooling and lamp housings. It is applied in the direction of detecting the appearance of fluid at the leak point and using liquid/vacuum degree for liquid tightness measurement. It can solve the problems of low work efficiency, easy damage to the sealing ring, time-consuming and laborious , to avoid the disassembly and assembly of the sealing ring, and it is not easy to be damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

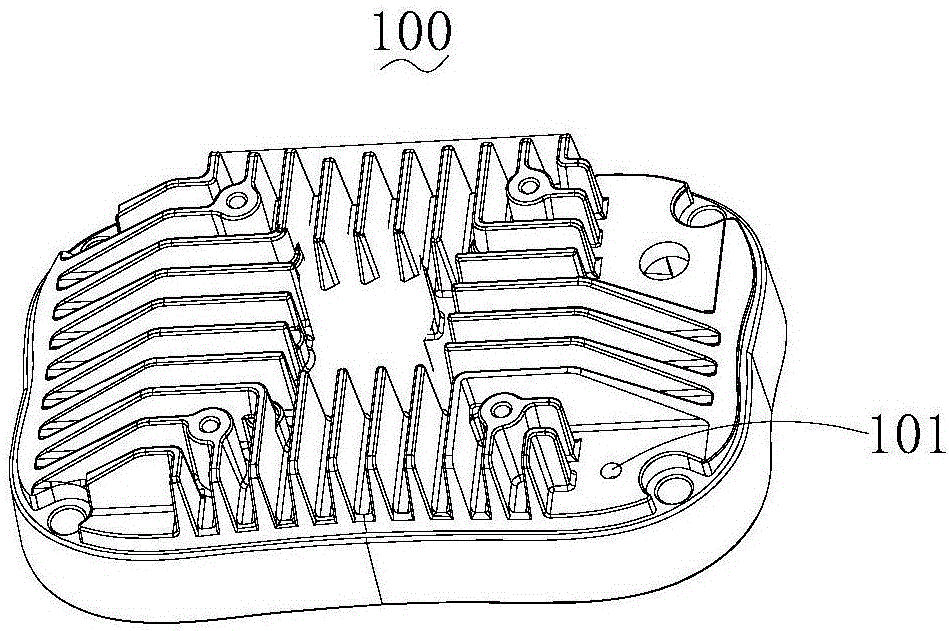

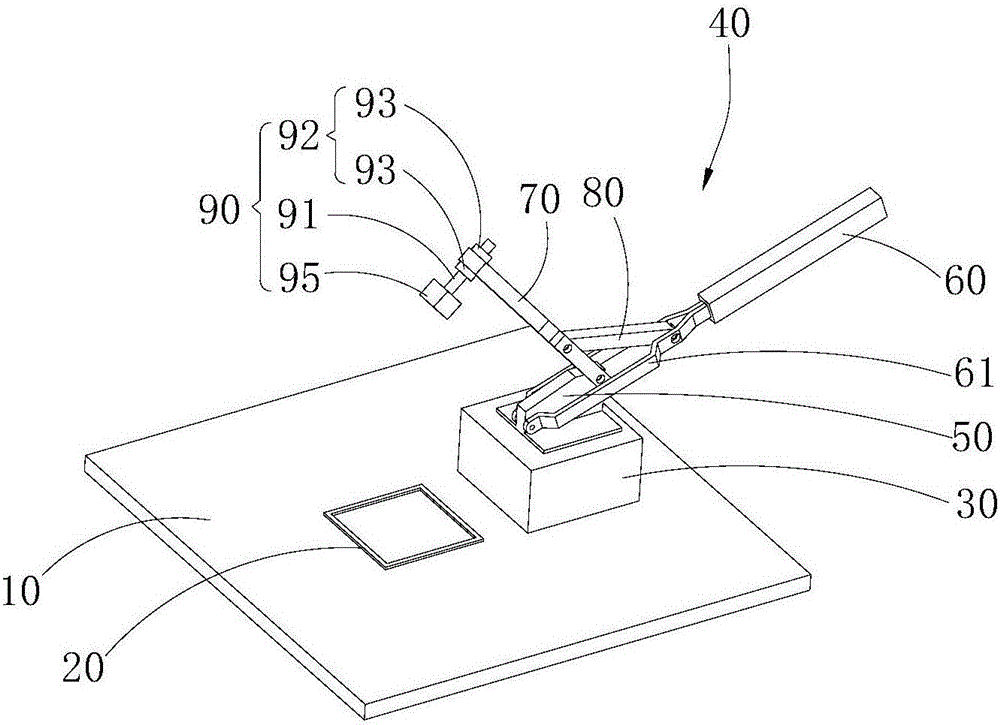

[0027] Such as figure 2 As shown, this embodiment discloses a die-cast lamp housing leak detection and clamping tool for clamping the die-cast lamp housing. The die-cast lamp housing leak detection and clamping tool includes a workpiece table 10, a sealing ring 20, and a workpiece table 10. The quick clamping table 30 and the quick clamping device 40 on the upper part of the workpiece table 10 are provided with an annular groove, a sealing ring 20 is installed in the annular groove, the quick clamping table 30 is located on one side of the sealing ring 20, and the quick clamping device 40 is installed in The quick clamping table 30 is used to press the die-cast lamp housing on the sealing ring 20 to seal the inner cavity of the die-cast lamp housing. (Pay attention to the size ratio of 20, it is best to add a picture, 100 according to the corresponding figure 2 Put in)

[0028] The quick clamping device 40 includes a support 50, a handle 60, an elastic power rod 61, an actuator...

Embodiment 2

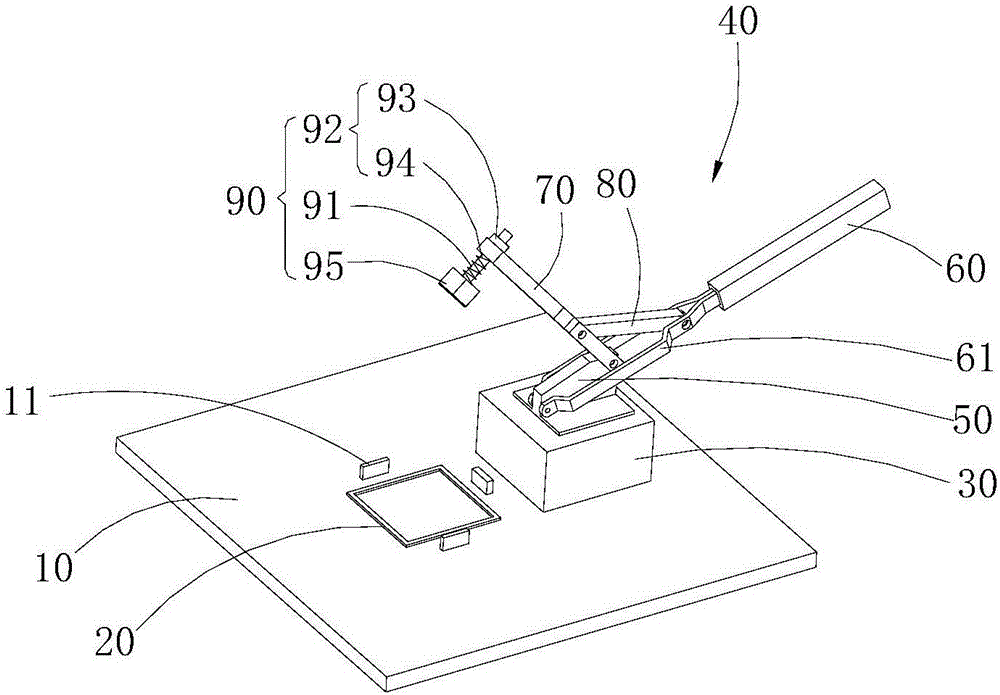

[0037] Such as image 3 As shown, the difference between this embodiment and the first embodiment is that the corresponding sealing ring 20 on the workpiece table 10 is provided with a die-cast lamp housing limit structure, which is used to make the die-cast lamp housing press correctly on the sealing ring 20 to ensure The sealing ring can seal the inner cavity of the die-cast lamp housing.

[0038] In this embodiment, the die-cast lamp housing limit structure is a limit block 11 provided around the sealing ring 20. Of course, the limit structure of the die-cast lamp housing is not limited to this. In other embodiments, the limit structure of the die-cast lamp housing can also be a limit groove matched with the die-cast lamp housing, and the limit groove is provided with a ring for installing the sealing ring 20 Groove.

[0039] In this embodiment, the fixing structure 92 is a buffer spring 94 and a fastening nut 93. The buffer spring 94 is sleeved on the round rod 91 and is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com