Estimation method of equivalent thermal conductivity of unidirectional fiber toughened composites based on gap defect identification

A technology of toughening composite materials and equivalent thermal conductivity, applied in the field of engineering thermophysics, can solve the problems of ETC prediction deviation, heat transfer deviation, difficult to reflect, etc., and achieve the effect of improving the prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with the accompanying drawings.

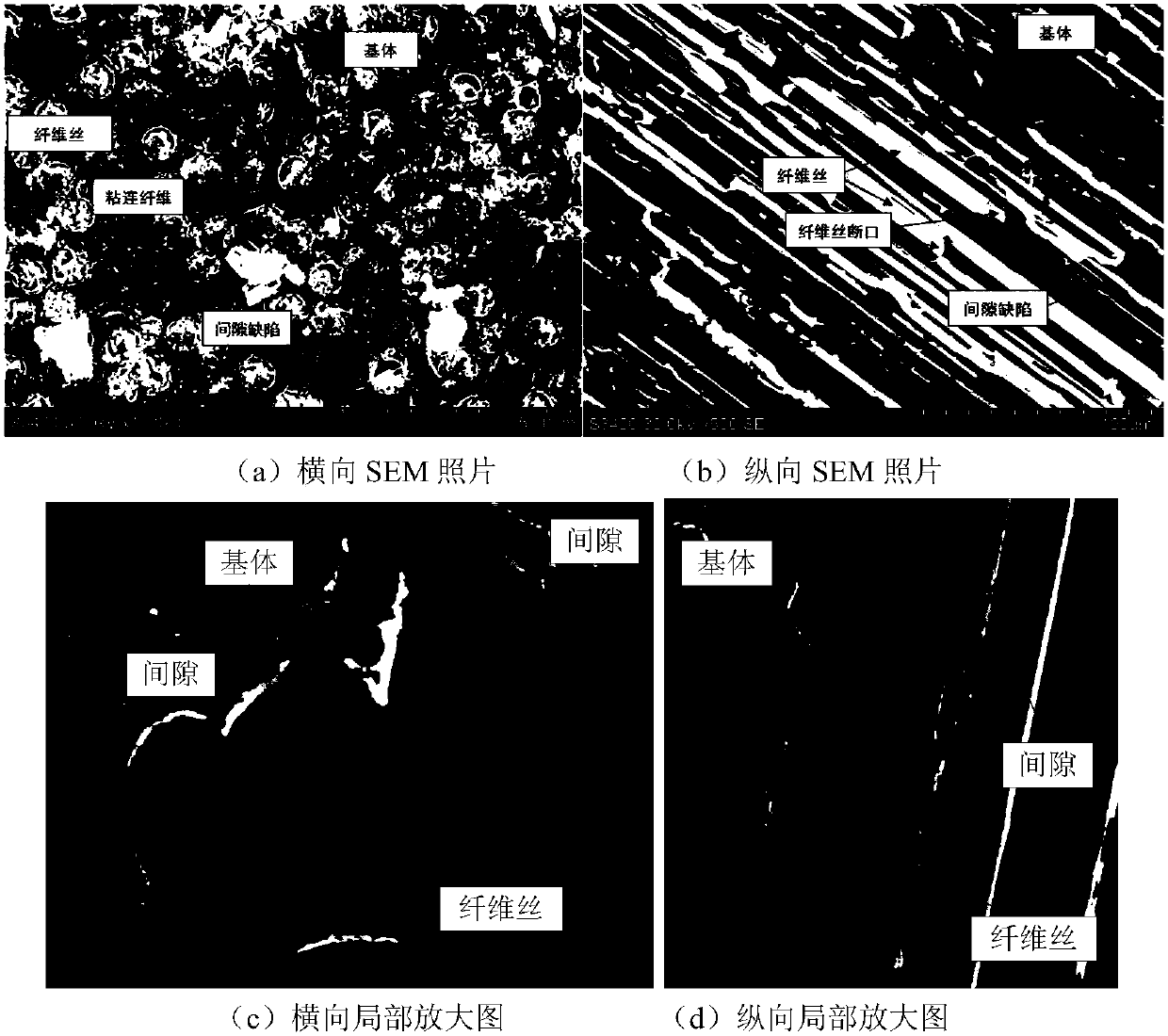

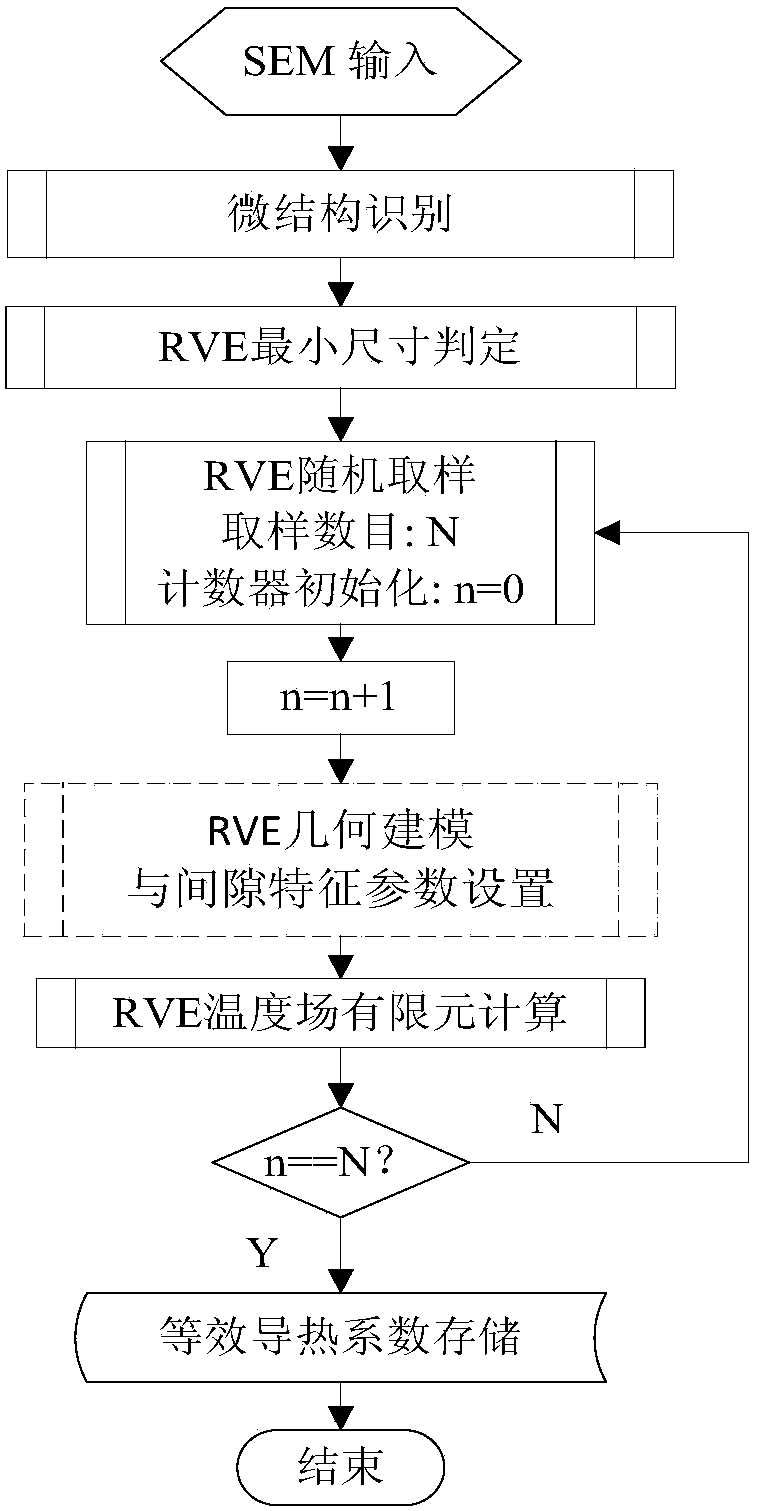

[0058] Such as figure 1 A method for estimating the equivalent thermal conductivity of unidirectional fiber-reinforced composites based on the identification of gap defects is shown.

[0059] the following to figure 1 The SEM photo of the microstructure of the carbon fiber epoxy resin-based unidirectional fiber toughened composite material with a fiber volume ratio of 50% is taken as an example to introduce the embodiment of the present invention.

[0060] in figure 1 (a) is a photo of the transverse cross-section of the material. In the figure, the bright-colored, circular or elliptical area represents the cross-section of the fiber, and the relatively darker surrounding area is the resin matrix. It can be seen from the photos that the matrix is generally dense, the fibers are randomly arranged in the matrix, and the positions are scattered, and some fibers appea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com