Motor of dry grinding machine

A machine-motor, dry-grinding technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems that the coffee cannot be completely ground, affect the use effect, and the motor vibrates greatly, so as to improve the continuous running time and improve the grinding effect. , the effect of noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

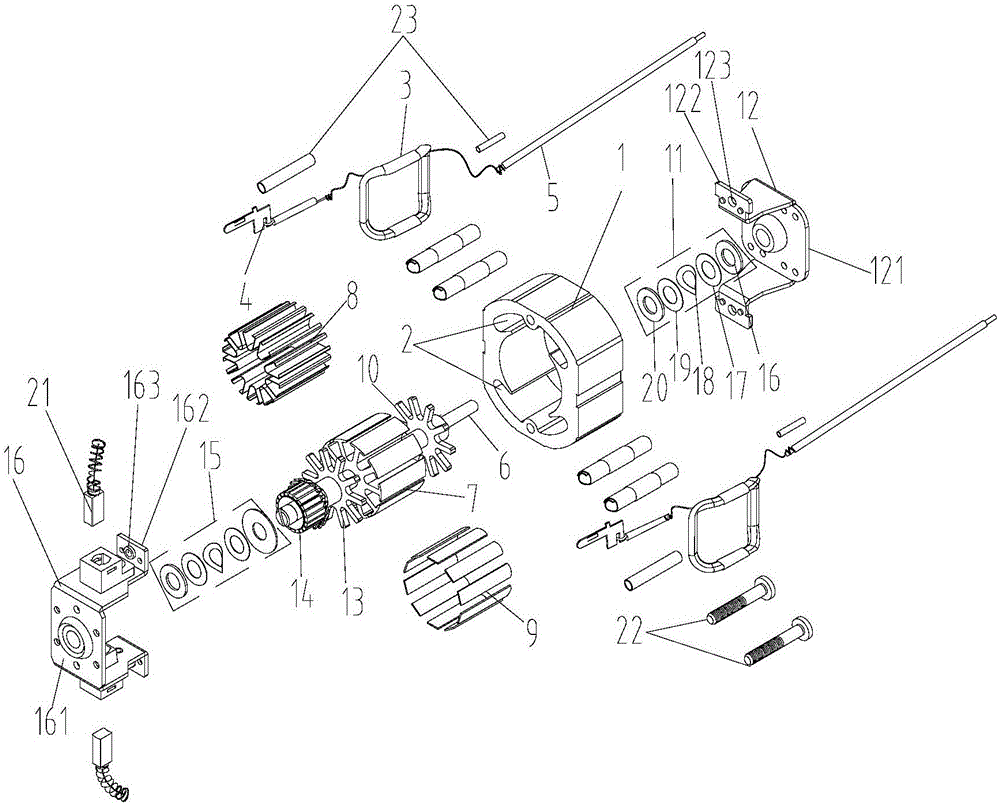

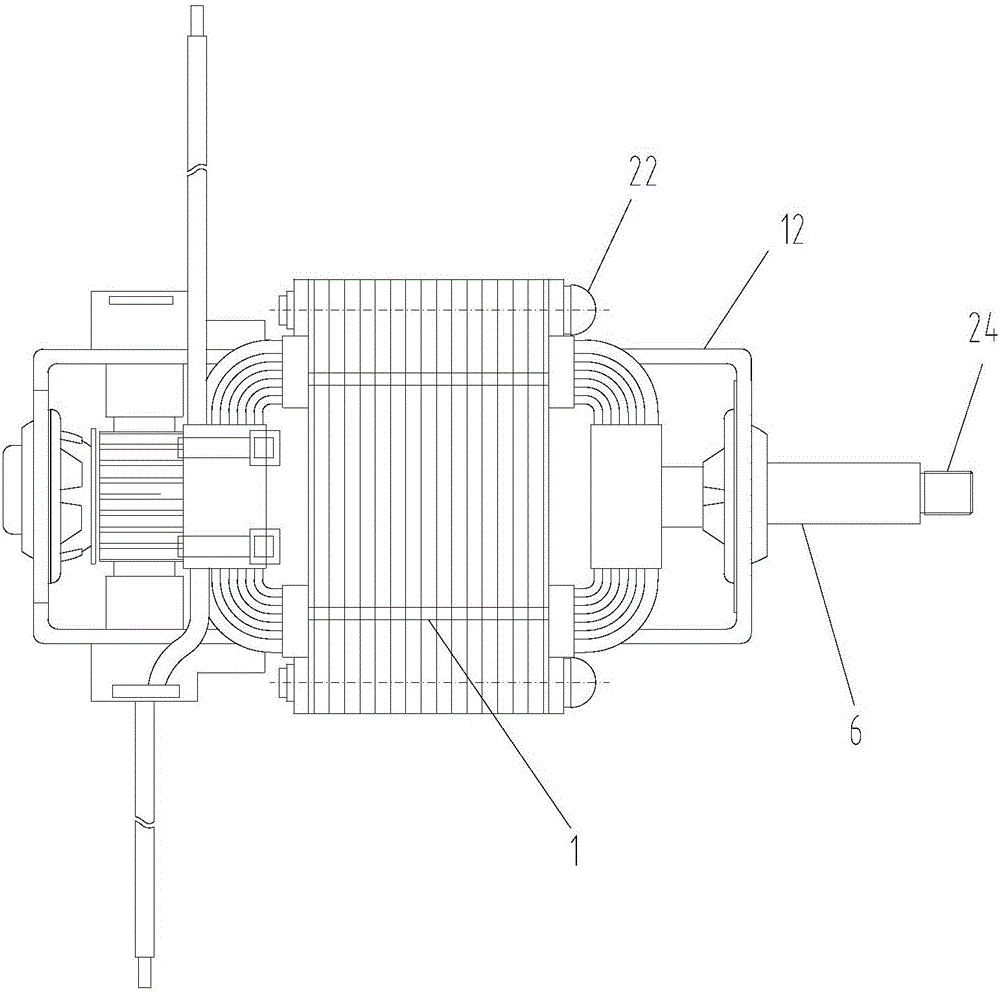

[0013] Example. Dry mill motor, constituted as figure 1 and 2 As shown, including the stator core 1, a pair of grooves 2 are respectively provided on the inner wall of both sides of the stator core 1, and a stator enameled wire 3 is provided in each pair of grooves 2, and a male terminal 4 is connected to one end of the stator enameled wire 3, and a male terminal 4 is provided at the other end. There are lead wires 5; the stator core 1 is provided with a rotor core 7 with a rotor shaft 6, and the rotor core 7 is provided with slot wedges 9 through insulating paper 8, and the front side of the rotor core 7 is sequentially provided with Front end plate 10, front meson group 11 and front bracket 12, rear end plate 13, commutator 14, rear meson group 15 and rear bracket 16, front meson group 11 and re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com