Method for checking whether motor support is installed firmly or not

A technology for motor bases and bases, applied in electromechanical devices, manufacturing motor generators, measuring devices, etc., can solve the problems of consuming a lot of manpower and material resources, economic losses, and prolonging the construction period, avoiding complex work, prolonging service life, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

[0022] A method for checking whether the motor base is firmly installed, characterized in that the steps are as follows:

[0023] Step 1, the installation of the sensor,

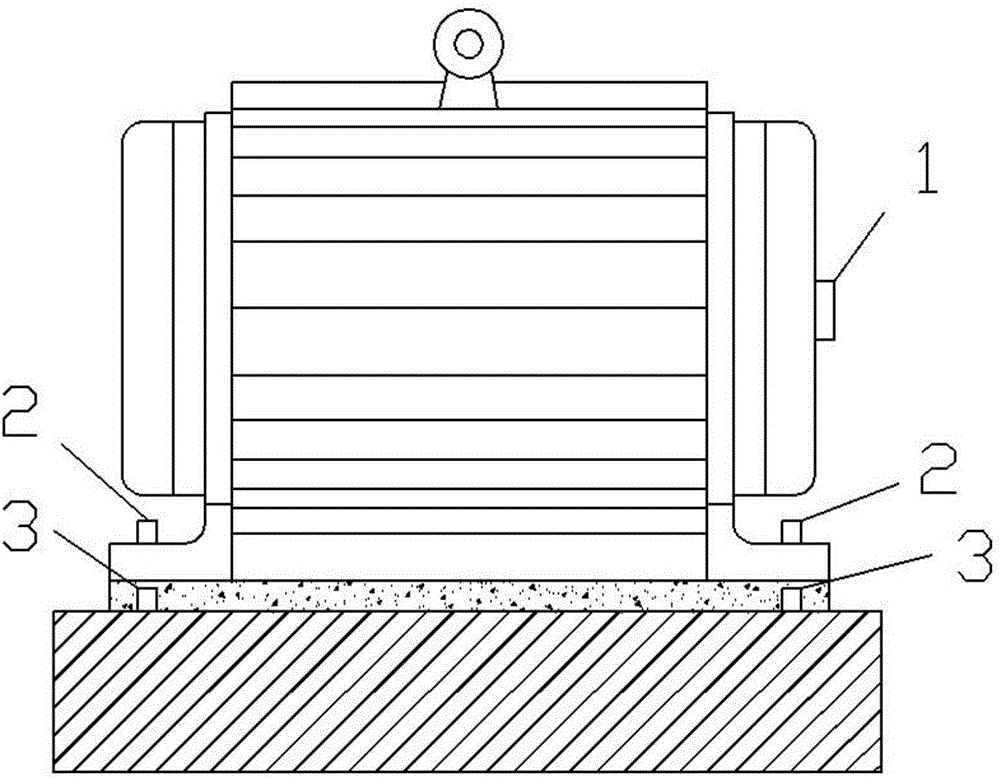

[0024] Install the base sensor 2 on the motor base, install the base sensor 3 on the base below the base, and install the phase detection sensor 1 on the surface of one end of the exposed journal of the motor. The phase detection sensor 1 is a laser sensor. A reflective strip is pasted on the rotor to reflect the light beam of the phase sensor 1, and the base sensor 2 and the base sensor 3 are both vibration sensors;

[0025] Step two, start th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com