Hollow Fiber Membrane Module for Platelet Suspension Cleaning

A fiber membrane and platelet technology, applied in the field of hollow fiber membrane modules, can solve the problems of complex operation, low platelet recovery rate, long processing time, etc., and achieve the effect of low total protein content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0186] After mixing and dissolving a mixture consisting of 15 parts of Yudel (registered trademark) polysulfone (P3500; Solbey Company), 8 parts of PVP (K90; ISP Company), 75 parts of DMAC and 2 parts of water at 90°C, the temperature was kept at 50°C. The mixture at ℃ was used as the membrane stock solution. In addition, a mixture obtained by adding 30 parts of PVP (K30; ISP company) to a mixed solution consisting of 80 parts of DMAC and 20 parts of water and mixing and dissolving it was used as a core liquid.

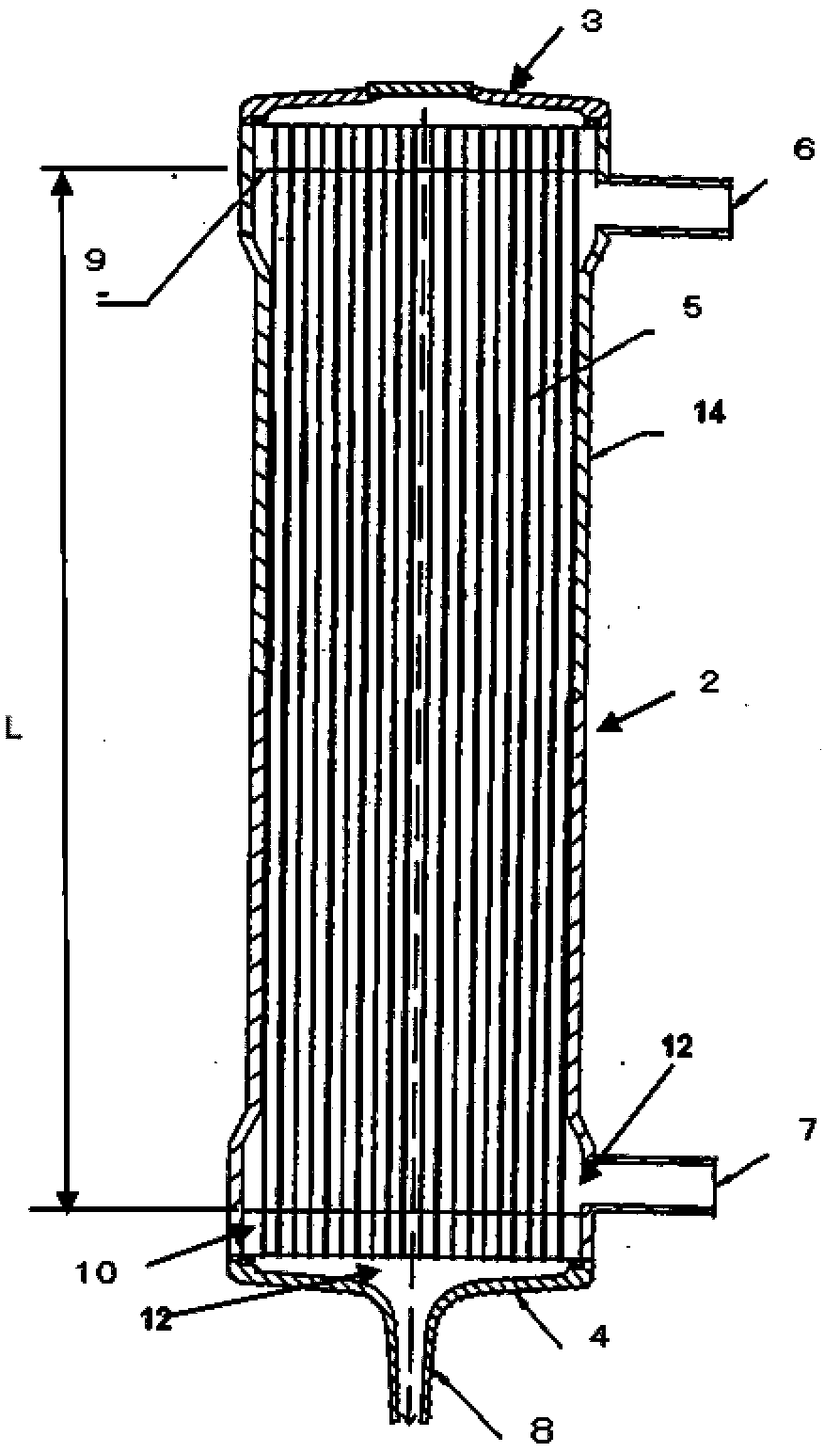

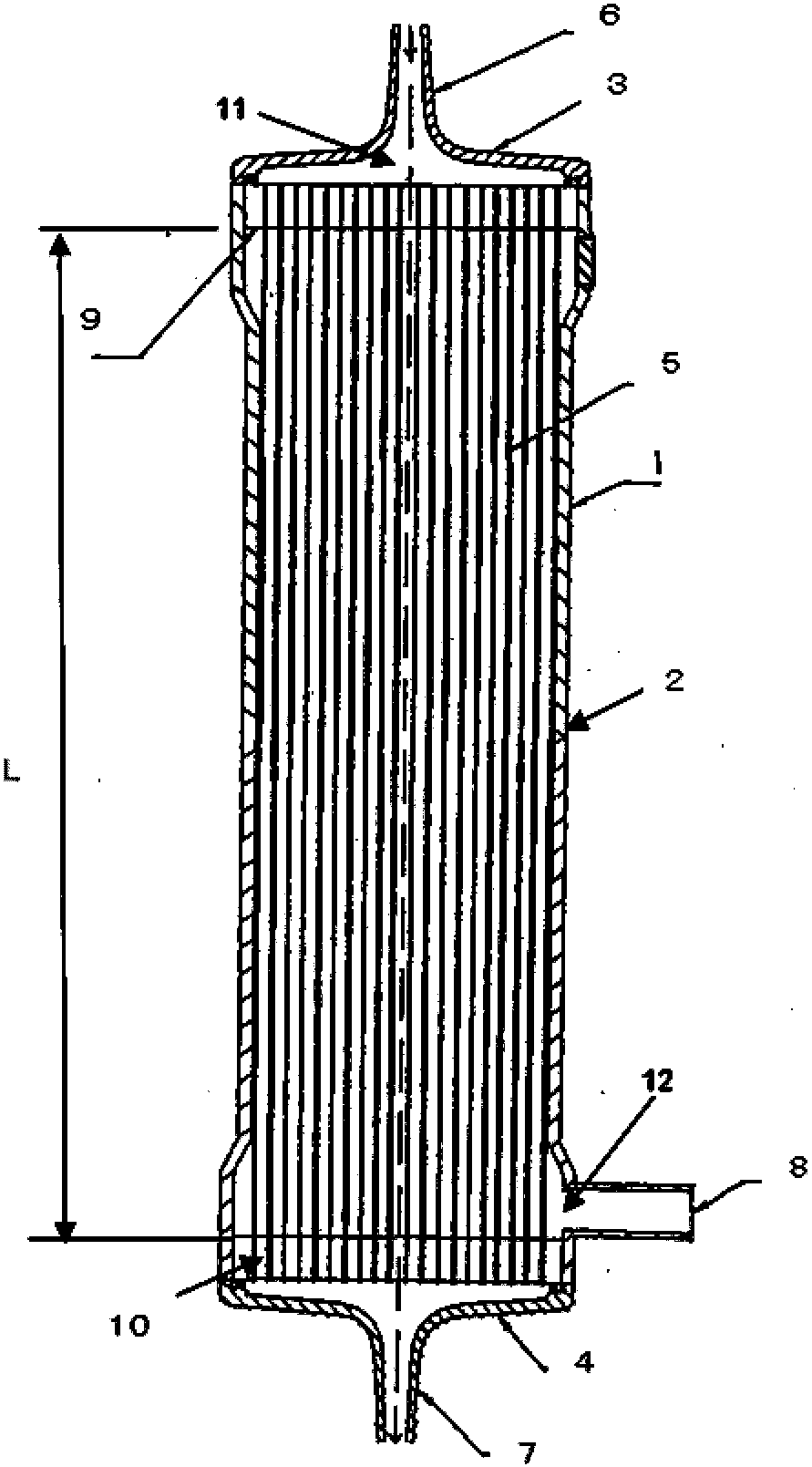

[0187] Using a hole-type double-cylindrical nozzle with an outer diameter of 1.0mm / inner diameter of 0.7mm, the film-forming stock solution is sprayed from the outer cylinder at the same time, and the core solution is sprayed from the inner cylinder, making it pass through the length set at 30°C After the dry part of 70mm was formed, it was immersed in a 90°C coagulation bath containing a mixed solution consisting of 85 parts of water and 15 parts of DMAC to solidify ...

Embodiment 2

[0193] A hollow fiber membrane module was produced in the same manner as in Example 1, except that the inner diameter of the cylindrical member was 44 mm, the volume of the top cover was 6.4 mL, and the number of inserted hollow fiber membranes was 5243.

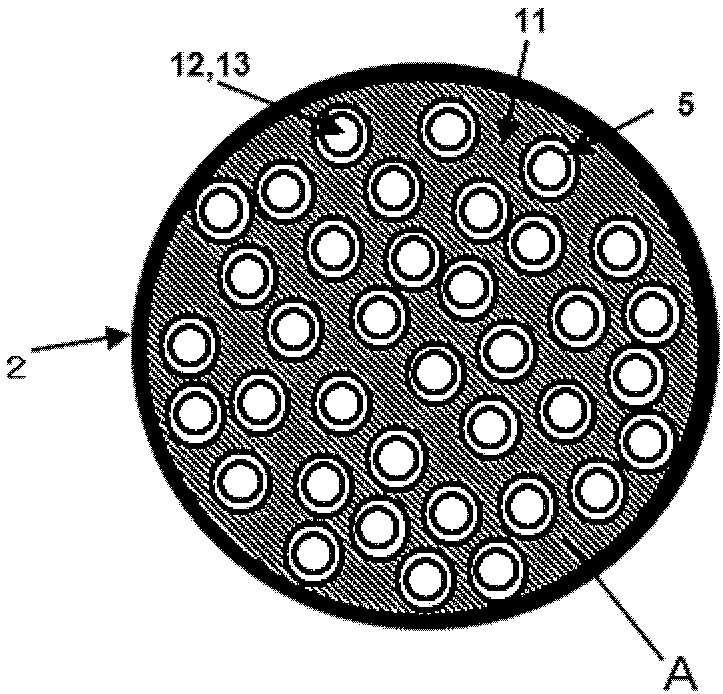

[0194] The effective length (L) of the hollow fiber membrane is 255mm, and the cross-sectional area (A) of the hollow part of the hollow fiber membrane (the cross-sectional area of the inflow side space perpendicular to the length direction of the shell) is 0.00037m 2 . Therefore, the value of the ratio (L / A) of the effective length (L) of the hollow fiber membrane to the cross-sectional area (A) of the hollow portion of the hollow fiber membrane (L / A) is 689m -1 . The volume of the inflow-side space of the hollow fiber membrane module was 118 mL. The water permeability of the hollow fiber membrane module is 95mL / Pa / hr. The porosity of the surface of the hollow fiber membrane in the inflow side space is 17.3%, and the p...

Embodiment 3

[0197] A hollow fiber membrane module was produced in the same manner as in Example 1, except that the inner diameter of the cylindrical member was 40 mm, the volume of the top cover was 5.3 mL, and the number of inserted hollow fiber membranes was 4494.

[0198] The effective length (L) of the hollow fiber membrane is 255mm, and the cross-sectional area (A) of the hollow part of the hollow fiber membrane (the cross-sectional area of the inflow side space perpendicular to the length direction of the shell) is 0.00032m 2 . Therefore, the value of the ratio (L / A) of the effective length (L) of the hollow fiber membrane to the cross-sectional area (A) of the hollow portion of the hollow fiber membrane (L / A) is 796m -1 . The volume of the inflow-side space of the hollow fiber membrane module was 101 mL. The water permeability of the hollow fiber membrane module is 82mL / Pa / hr. The porosity of the surface of the hollow fiber membrane in the inflow side space was 17.3%, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com