fuel cell system

A technology of fuel cell system and fuel cell stack, which is applied in the direction of fuel cell, fuel cell additive, fuel cell heat exchange, etc., to achieve the effect of improving efficiency, low cost, and efficient fuel conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

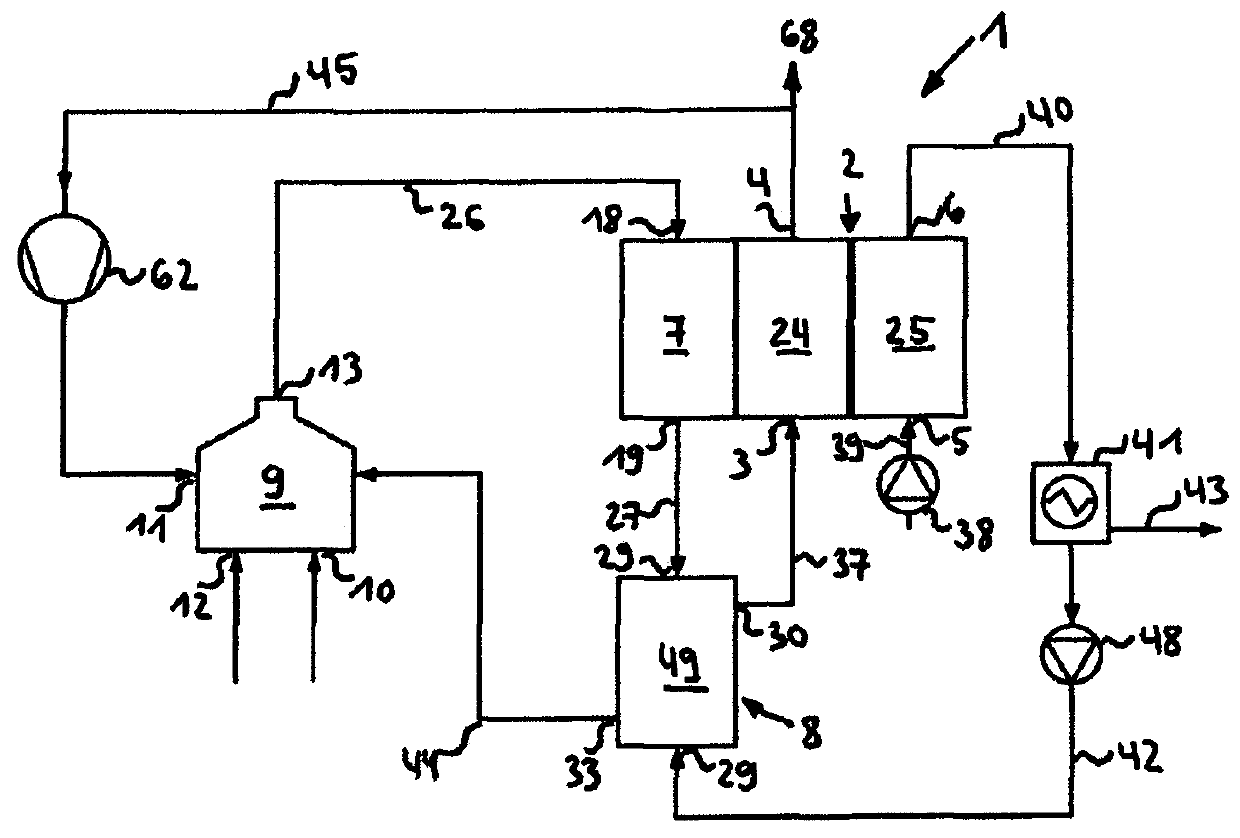

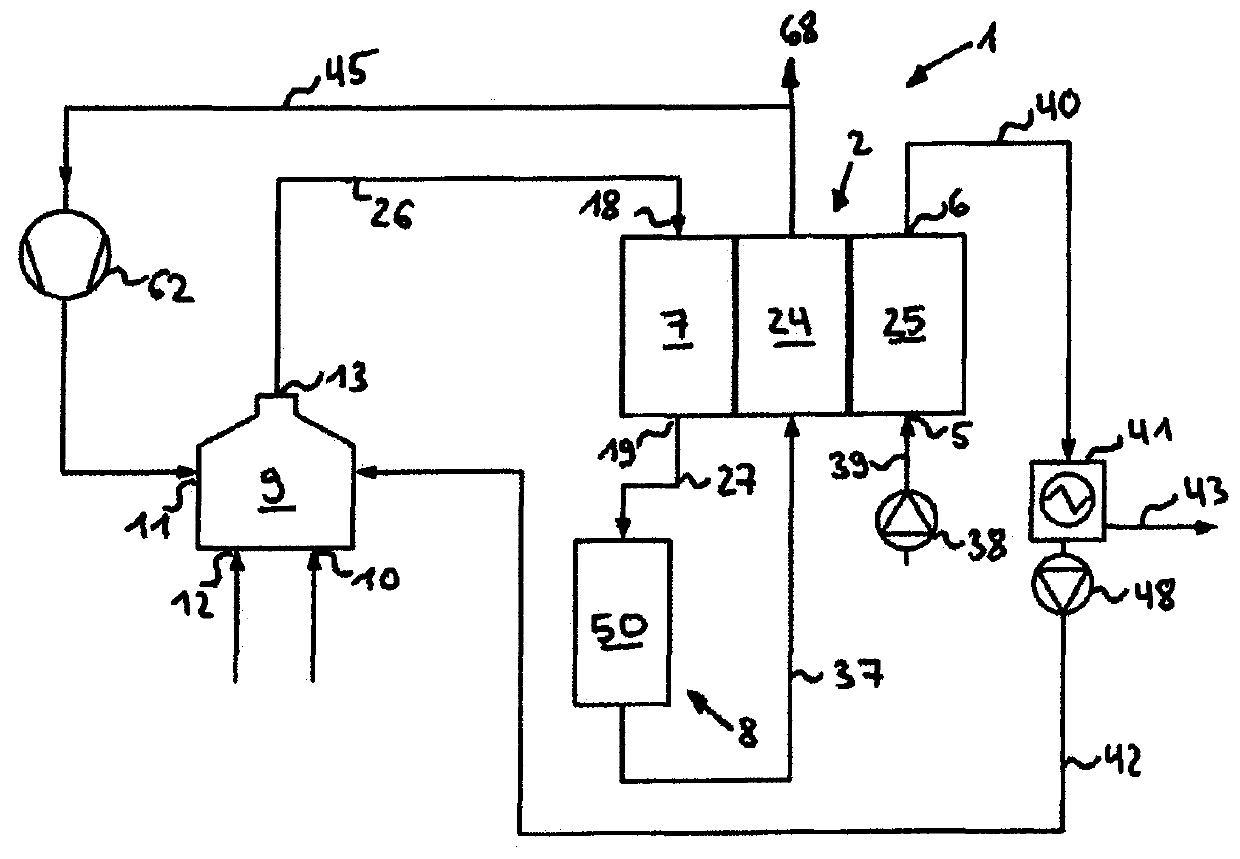

[0101] The fuel cell system 1 comprises, according to a first embodiment, a fuel cell or a fuel cell stack 2 having an anode 24 with an anode inlet 3 and an anode outlet 4 and a cathode 25 with a cathode inlet 5 and a cathode outlet 6 ( figure 1 ).

[0102] Furthermore, there is a reformer unit 7 thermally coupled to the fuel cell stack 2 for providing reformate or anode fluid, said reformer unit being connected upstream of the anode inlet 3 and present between the reformer unit 7 and the anode A treatment device (Aufbereitungseinrichtung) 8 is provided between the inlets 3 for removing untreated fuel and pollutants from the reformate.

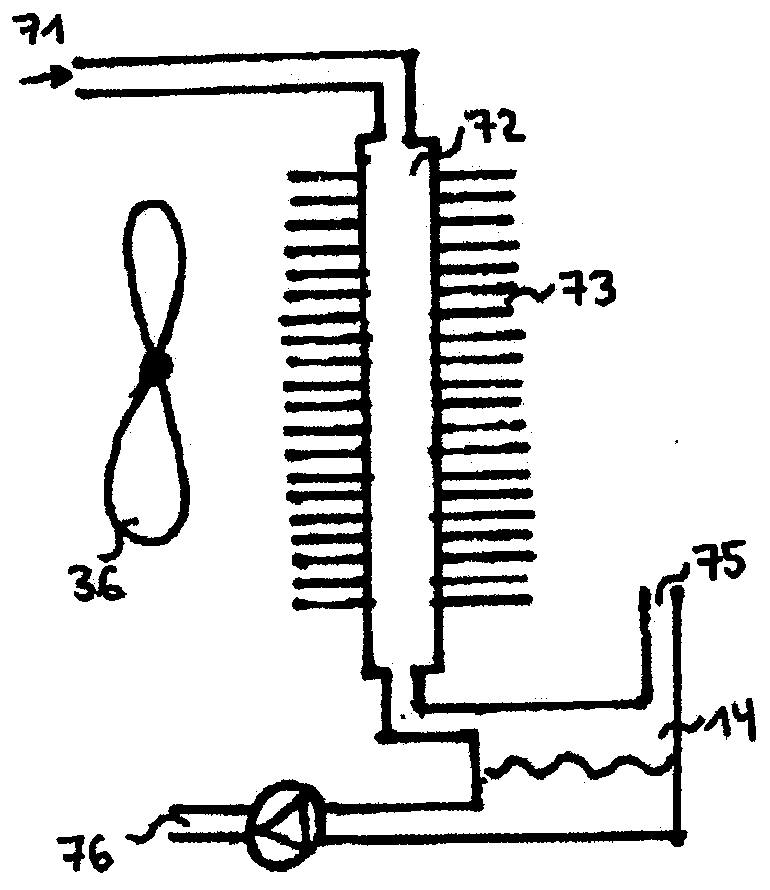

[0103] Furthermore, the fuel cell system 1 has a humidification unit 9 . The humidification unit 9 is constructed according to the humidification unit described in WO 2010 / 066900 and comprises: a humidification chamber configured to contain a fuel-containing liquid; an inlet 10 into the humidification chamber for delivering the fuel-containi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com