Production technology of dried soybean gluten

A production process and technology for drying bean tendons, which are applied in cheese substitutes, dairy products, applications, etc., can solve the problems of poor elasticity and poor taste of the inner layer of bean tendons and bean tendons, and achieve good elasticity, uniform elasticity distribution, and good elasticity. effect of taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

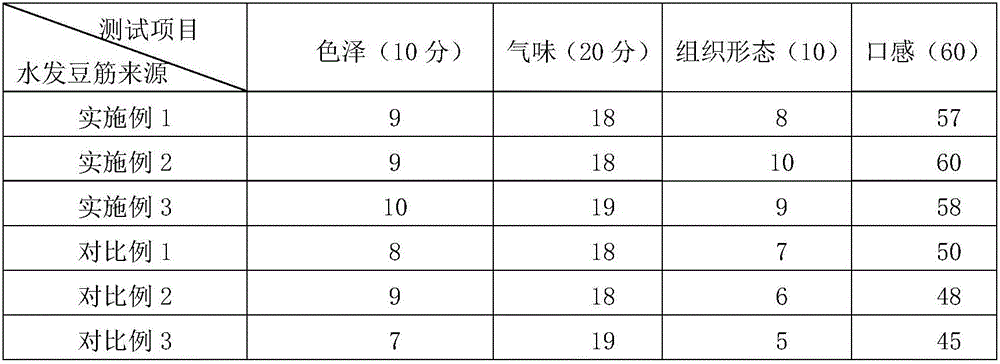

Examples

Embodiment 1

[0031] The dry bean curd production technology of the present embodiment comprises the following steps:

[0032] S1) Raw material screening: remove impurities in soybean raw materials to ensure high quality of soybean raw materials;

[0033] S2) Raw material soaking: Soak the screened soybeans in water, specifically, pour the soybeans and water into the soybean soaking tank in a weight ratio of 1:4 for uniform soaking, and the soaking time is 7 hours;

[0034] S3) Refining: Use special suction equipment to suck the soaked soybeans into the automatic refiner and grind them into a clear paste or slurry, and inject the ground soybean milk containing bean dregs into the special soybean milk tank for steam heating and heat preservation to 90°C;

[0035] S4) Filtration: the heated soymilk is separated from pulp and residue through a special soymilk filter;

[0036] S5) Boiling: Pour the separated soymilk without bean dregs into a special container, send it to the production worksho...

Embodiment 2

[0049] The difference from Example 1 is that in this example: S2) the soaking time of the raw materials is 10 hours; S7) the drying temperature of the bottom layer is 60° C., and the drying time is 4 hours; S9) the drying time of the second layer is The drying temperature is 70°C, and the drying time is 4 hours; S11) the drying temperature of the three-layer drying is 70°C, and the drying time is 5 hours; S13) the drying temperature of the four-layer drying is 75°C, and the drying The drying time is 3 hours; S14) The molding drying temperature is 65° C., and the drying time is 5 hours.

Embodiment 3

[0051] The difference from Example 1 and Example 2 is that in this example: S2) The soaking time of the raw materials is 8 hours; S7) The drying temperature of the bottom layer is 50 ° C, and the drying time is 5 hours; S9) The second layer The drying temperature for drying is 65°C, and the drying time is 5 hours; S11) the drying temperature for three-layer drying is 68°C, and the drying time is 5.5 hours; S13) the drying temperature for four-layer drying is 72 °C, the drying time is 3.5 hours; S14) The drying temperature for molding is 63 °C, and the drying time is 5.5 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com