Variable model

A model and ever-changing technology, applied in the direction of sewing tools, etc., can solve business disputes, waiting or re-appointment, etc., to achieve the effect of flexible and convenient pickup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

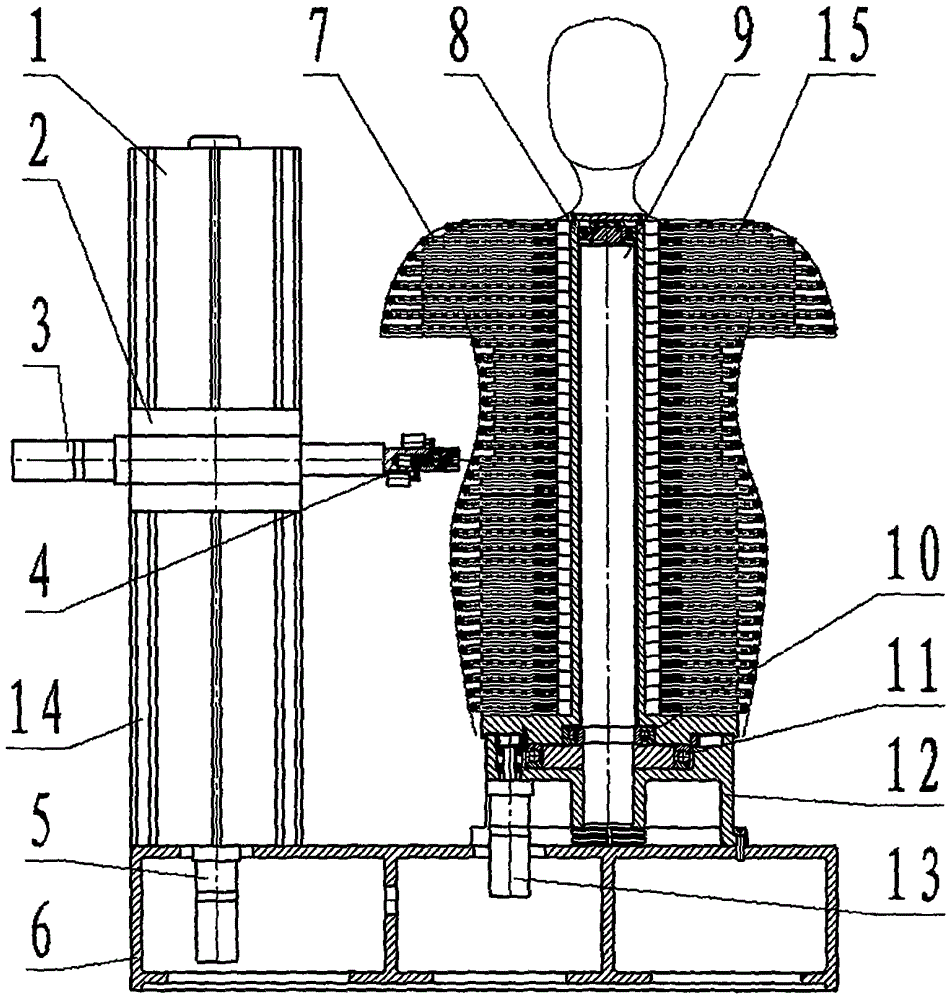

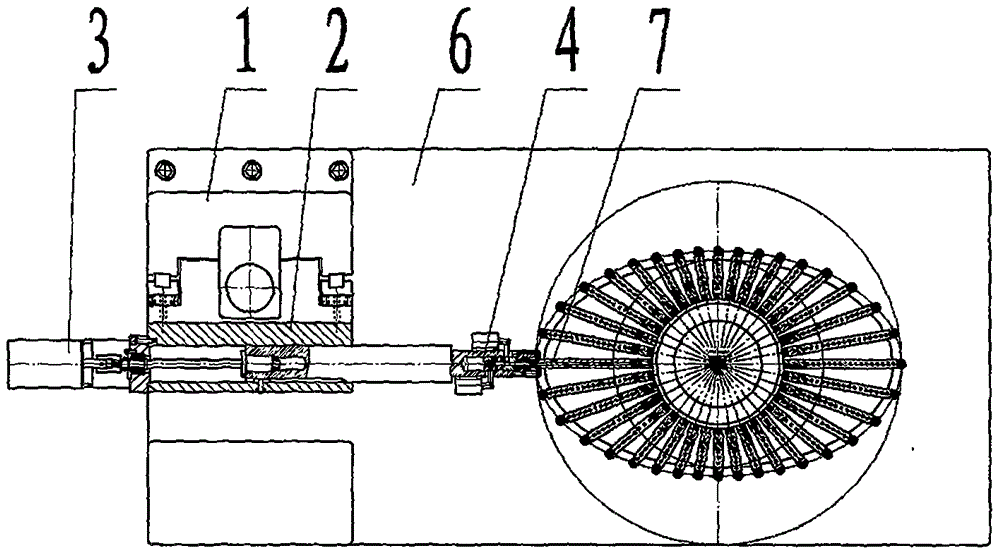

[0007] Referring to the accompanying drawings, the present invention provides a tailor-made variety model for the garment production industry, including a column 1, a skateboard 2, a lateral movement motor 3, a grasping manipulator 4, a vertical movement motor 5, a base 6, and a telescoping ball head Rod 7, supporting sleeve 8, vertical shaft 9, radial ball bearing 10, thrust ball bearing 11, slewing bracket 12, slewing motion motor 13, linear guide pair 14, supporting plate 15.

[0008] The column 1 is installed on the base 6, the column 1 is provided with a linear guide rail pair 14, the slide plate 2 is connected to the slider of the linear guide rail pair 14, and the vertical motion motor 5 drives the slide plate 2 to move up and down through a screw drive. , the grabbing manipulator 4 can complete the movement of grabbing the ball head telescopic rod 7 through the control of the cylinder, and the grabbing manipulator 4 is connected with the lateral movement motor 3 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com