Fully-automatic rice steaming machine capable of improving rice steaming quality

A fully automatic, rice steaming machine technology, applied in the field of kitchen utensils, can solve the problems of low degree of automation and poor quality of steamed rice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

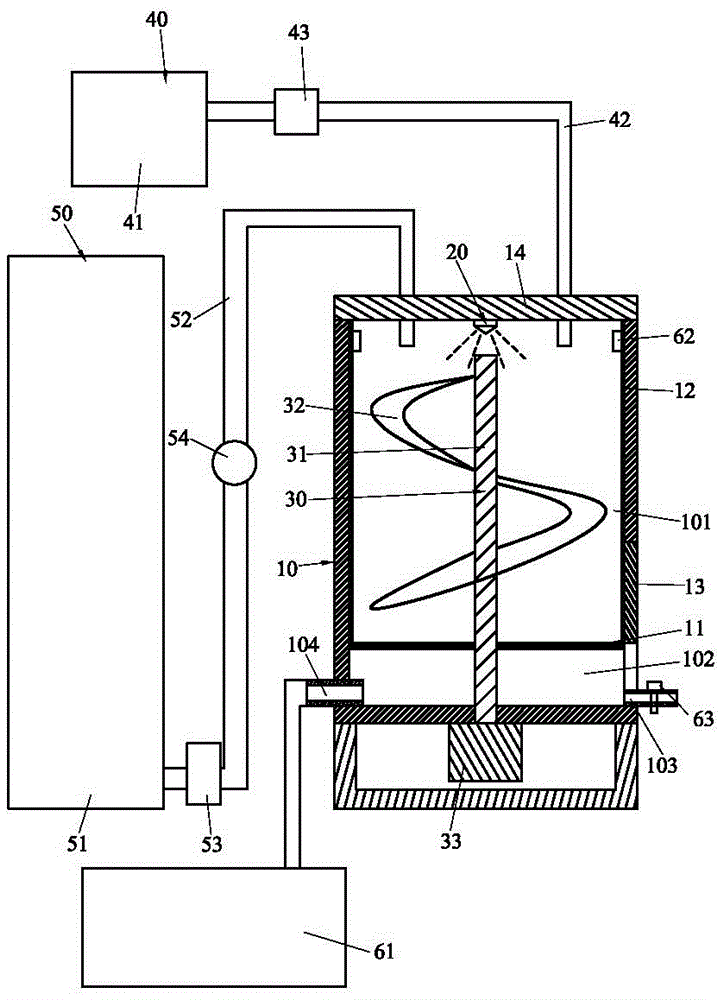

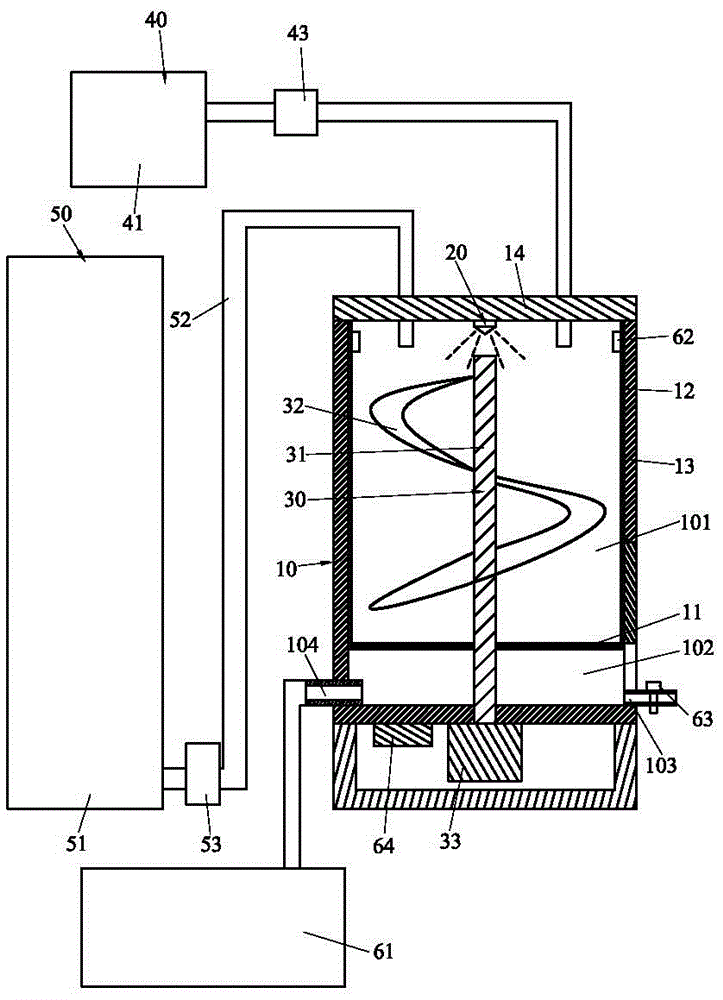

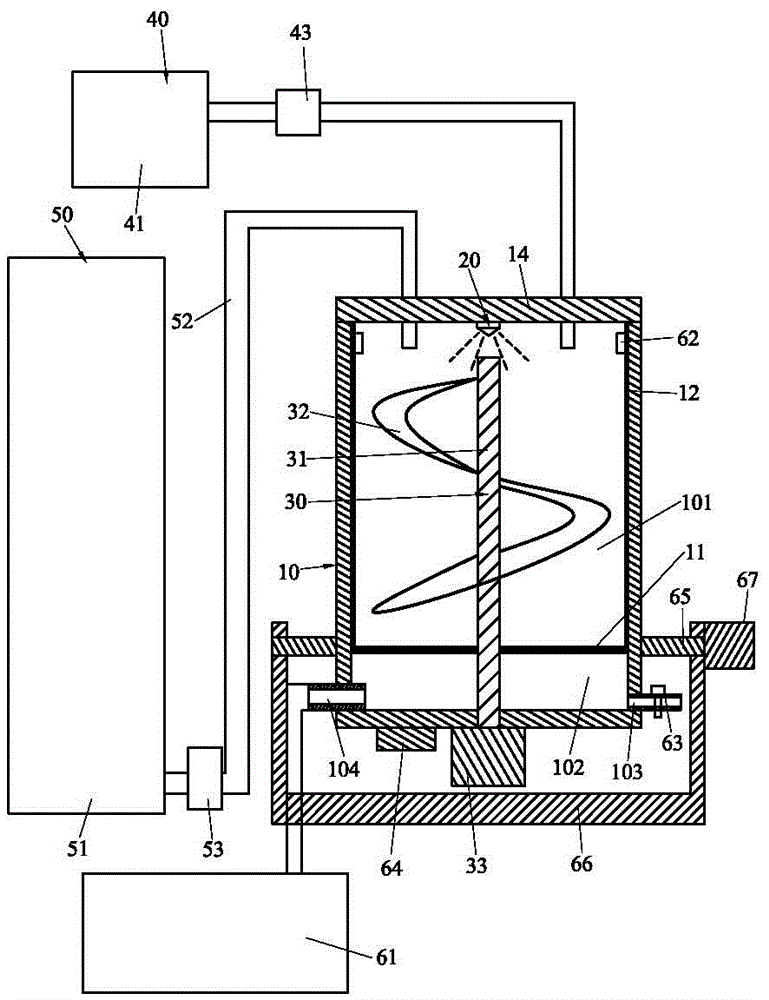

[0037] Please refer to figure 1 As shown, it shows the specific structure of the first preferred embodiment of the present invention, including a bucket body 10 , a spraying device 20 , an agitating device 30 , a water injection device 40 and a rice injection device 50 .

[0038] The barrel body 10 is provided with a screen 11, which separates the inside of the barrel body 10 to form a rice steaming chamber 101 and a steam chamber 102, the steam chamber 102 is located directly below the rice steaming chamber 101, and the barrel body 10 A drain port 103 and a steam port 104 are arranged on the top, and the drain port 103 and the steam port 104 are connected to the steam chamber 102; the steam port 104 is connected to the steam generating device 61, and the steam generating device 61 can use various methods such as burning wood, coal, gas, electricity, etc. Any way, unlimited fuel. In this embodiment, the barrel body 10 is made of stainless steel, and the inner wall of the rice...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com