A device and pulping process for fast and efficient preparation of clay puree

A clay and high-efficiency technology, which is applied in the field of rapid and efficient preparation of clay raw pulp and pulping technology, can solve the problems of complicated pulping process, high equipment maintenance rate, and small range of materials, so as to reduce the number of workers used and improve the pulping process. The effect of simple process and wide range of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

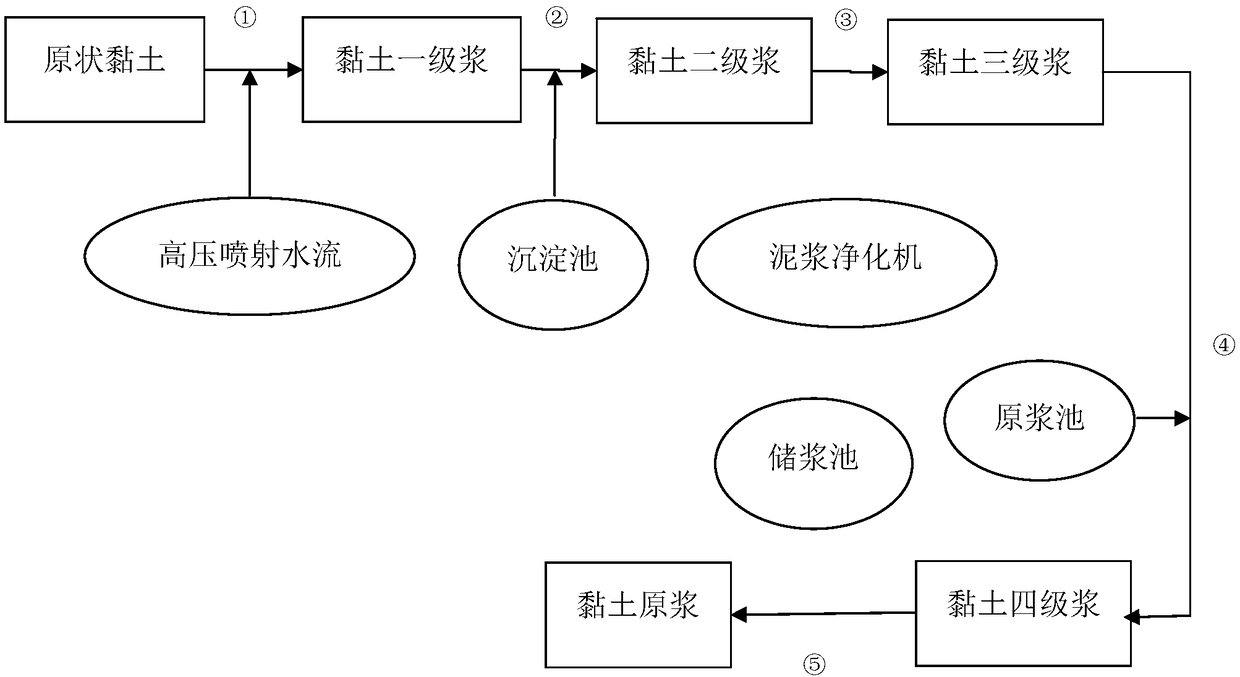

[0032] In order to clearly illustrate the solutions in the present invention, preferred embodiments are given below and detailed descriptions are given in conjunction with the accompanying drawings.

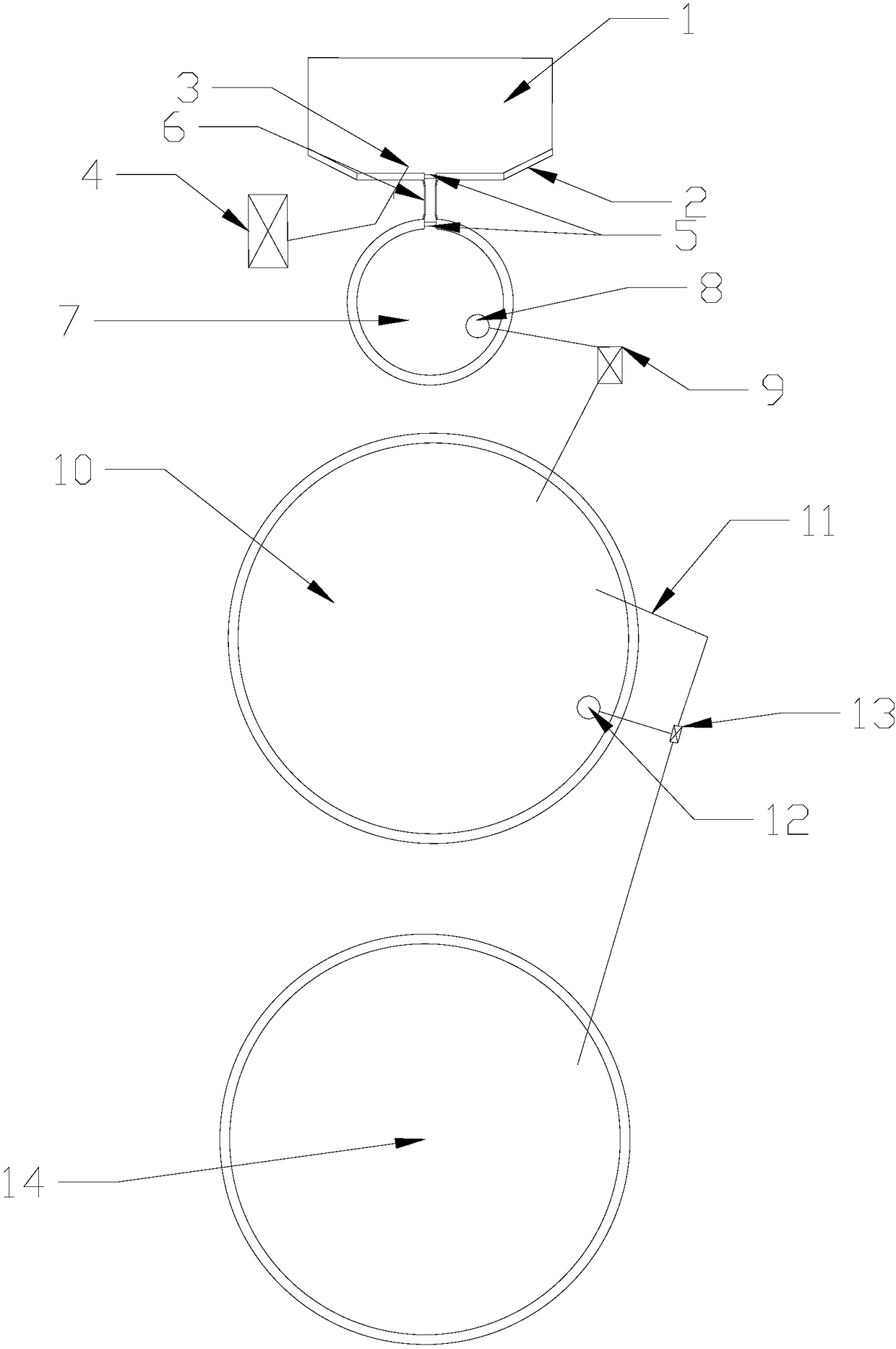

[0033] The pulping process in the present invention is a pulping process for preparing clay puree by using a device for quickly and efficiently preparing clay puree. In this embodiment, the device for quickly and efficiently preparing clay slurry includes a clay slurry preparation mechanism, a clay slurry sedimentation and impurity removal mechanism, a clay slurry mixing mechanism, and a clay slurry storage mechanism.

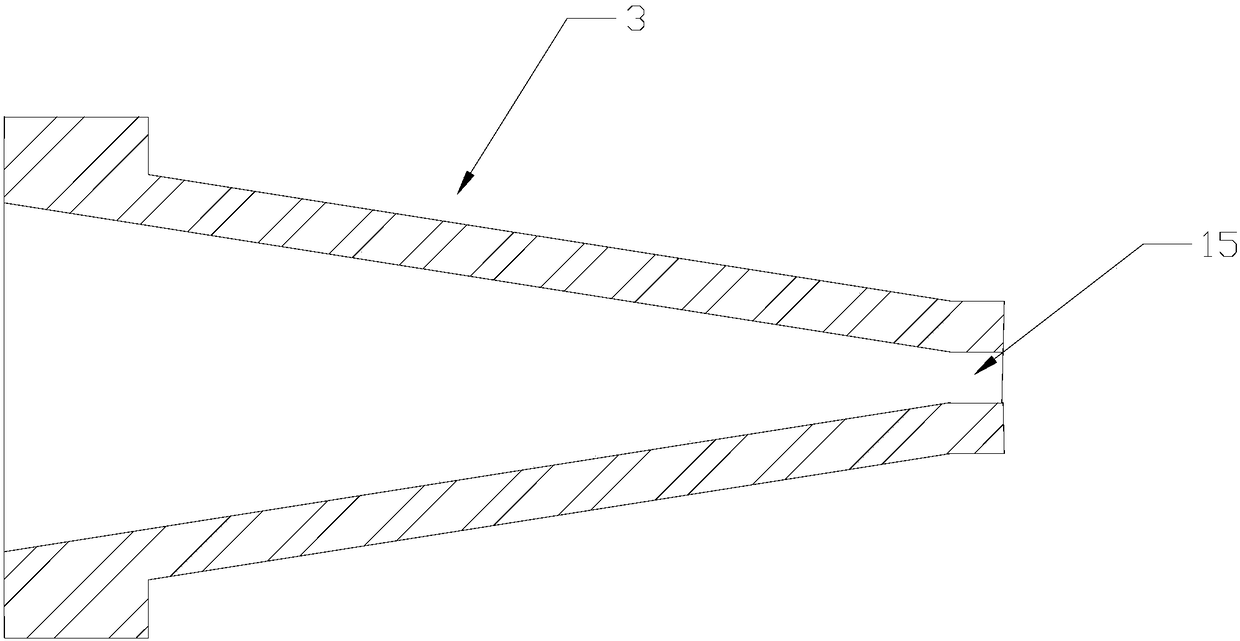

[0034] Among them, such as figure 1As shown, the clay slurry preparation mechanism includes a clay stacking mechanism, a mud pump 4, and a high-pressure nozzle 3 for pulping. The clay stacking mechanism includes a soil field and a mud retaining wall 2, and the mud retaining wall 2 is an anti-seepage mud retaining wall. wall 2, and the mud retaining wall 2 is prov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com