Polyurethane foaming process for thermal insulation pipe connector

A polyurethane and thermal insulation pipe technology is applied to containers, containers, packaging and other directions with multiple items, which can solve the problems of insufficient mixing in the foaming process, and achieve the effects of simple structure, low production cost and simple use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The polyurethane foaming process for the insulation pipe interface described in the present embodiment comprises the following steps:

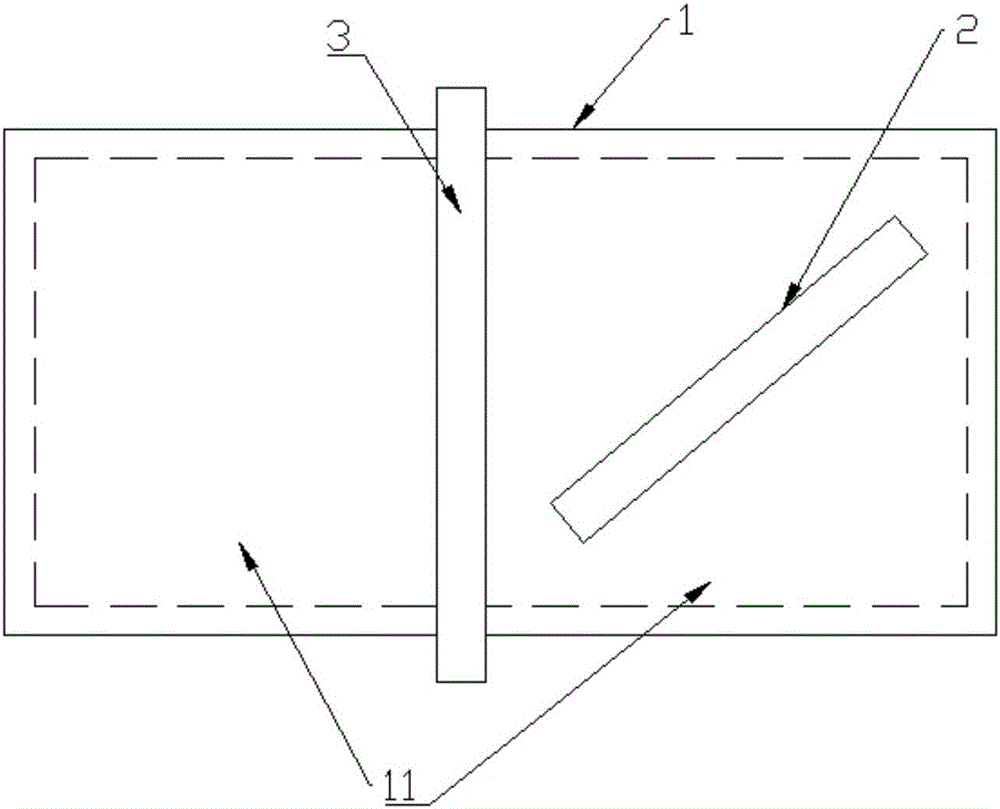

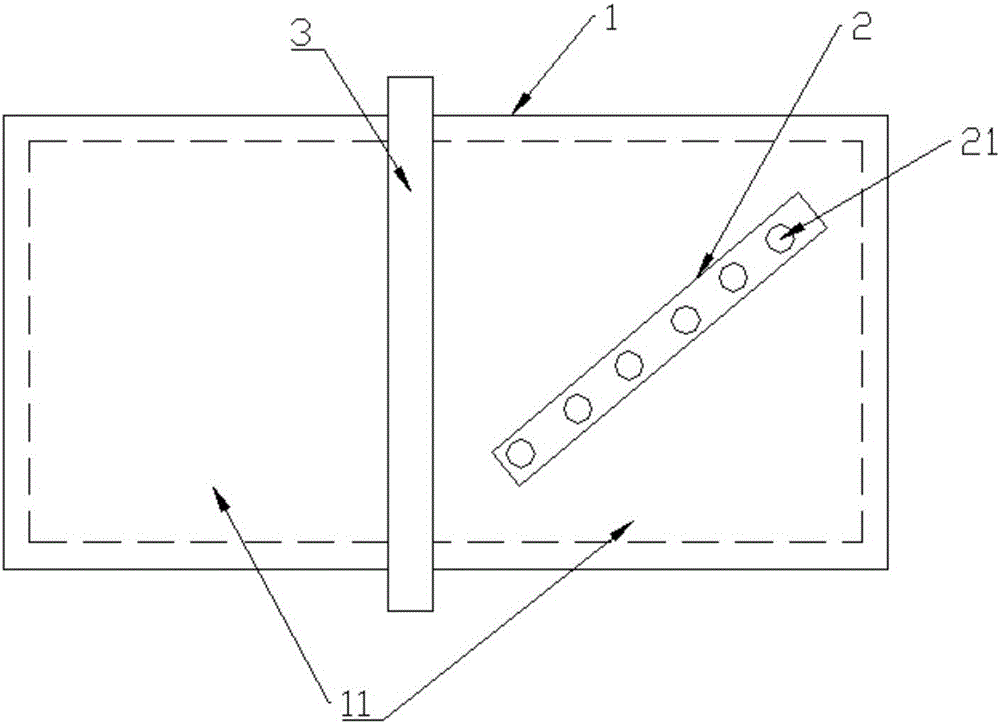

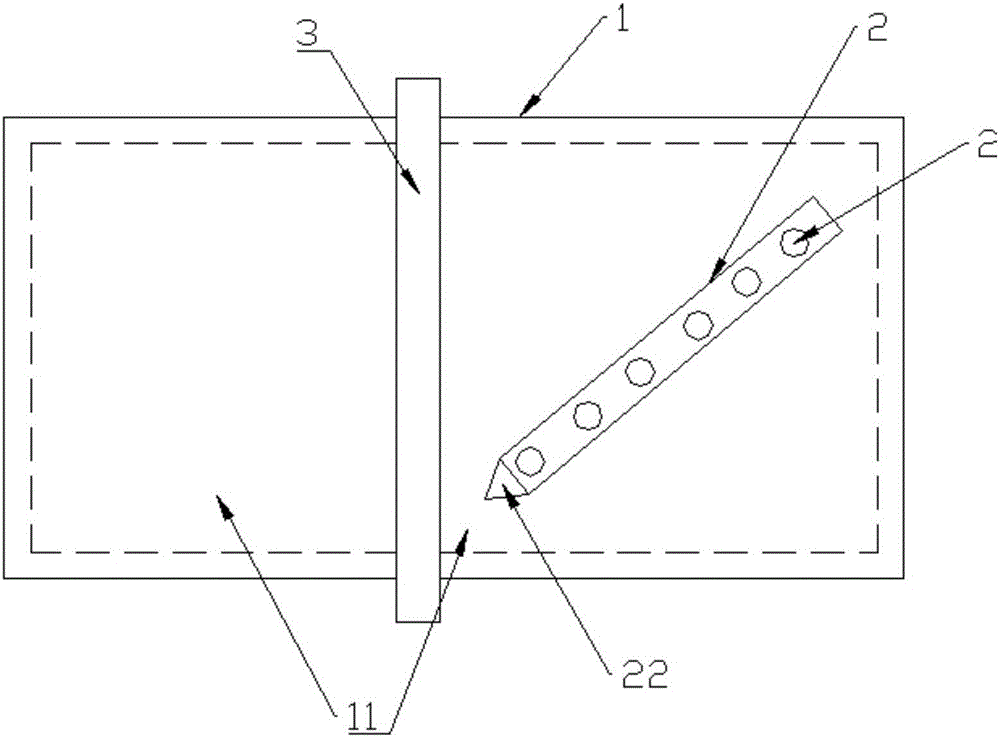

[0042] (a) Selection: Select a suitable packaging bag equipped with polyurethane foam material according to the size of the insulation pipe interface. The packaging bag includes a double-layer structure body 1 with edge sealing, and the body 1 is divided into two parts that can be connected. A sub-bag 11, A material and B material for polyurethane foaming are housed respectively in two sub-bags 11, as figure 1 Shown; After selecting the packaging bag of the corresponding specification, adjust the temperature of the foaming liquid to meet the temperature requirements before foaming. Then, determine the stirring time according to the relationship between the temperature outside the incubator and the operating time.

[0043] (b) stirring: get through the division between the two sub-bags 11, make the two sub-bags 11 communicate, and utili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com