Automatic waveform piece sorting equipment

An automatic sorting and corrugated sheet technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve problems such as difficulty in gearing, incomplete separation, and errors in multiple corrugated sheets, so as to avoid incomplete separation, simple structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

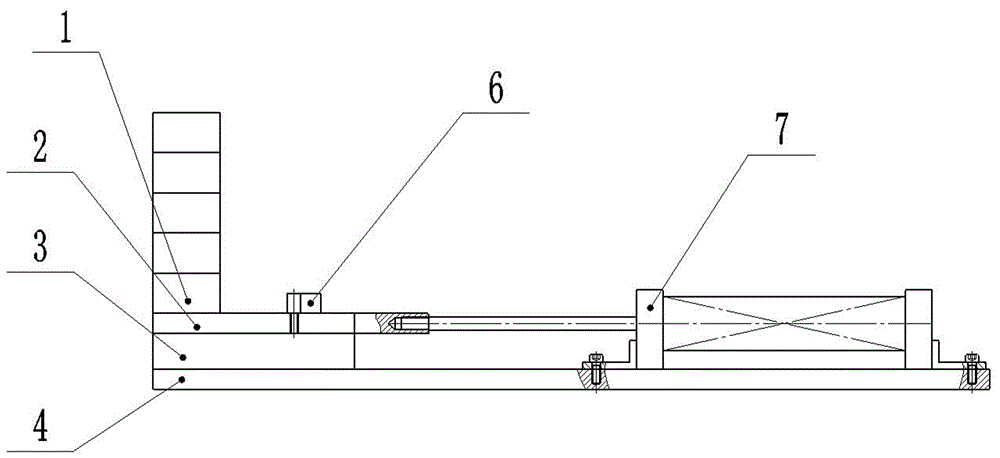

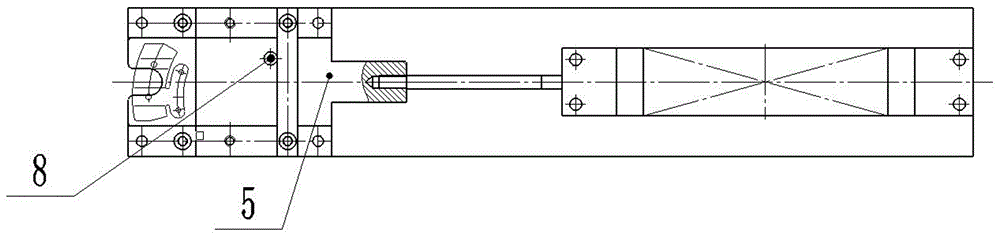

[0016] refer to Figure 1-2 , an automatic sorting device for corrugated sheets, including a mechanical part and an electrical part connected with the mechanical part, wherein:

[0017] The mechanical part includes a bottom plate 4, a material guide plate 1, a baffle plate 6, a slide plate 5, a guide plate 2, a limit pin 8 and a corrugated sheet charging groove. The baffle plate 2 is arranged on the guide rail bottom plate 3 and connected with the slide plate 5. On the guide rail, it is connected with the limit device so that the slide plate 5 can only slide in one direction. The guide plate 2 is connected with the material guide plate 1. The limit pins 8 are respectively arranged on both sides of the slide plate 5 and connected with the baffle plate 2. The corrugated sheet The charging trough is set on the material guide plate 1, and the material guide plate 1 feeds in and out through the guide rail on the corrugated sheet charging trough;

[0018] The electrical part includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com