Barrel plating method and electroplating cage for implementing barrel plating method

A barrel plating and cage technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of low efficiency and poor quality of electroplating processing, and achieve the effect of ensuring the quality of coating processing, increasing the probability of electrical contact, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

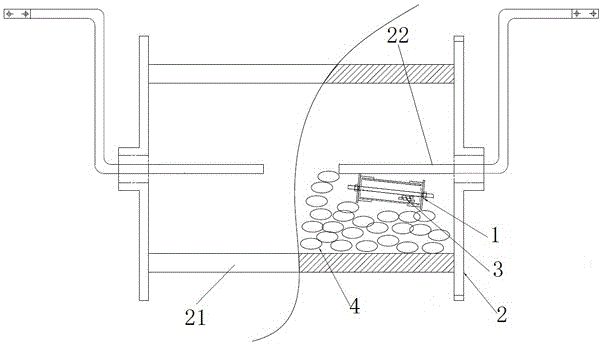

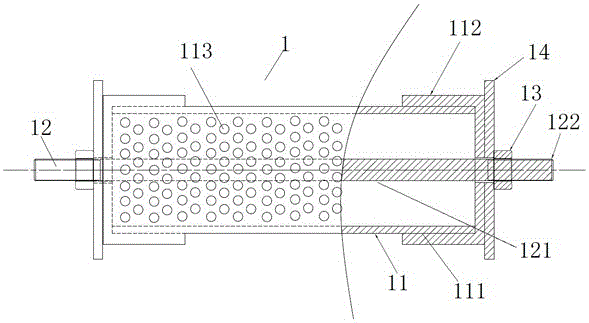

[0016] A specific embodiment of the electroplating cage of the present invention, such as Figure 1 to Figure 2 As shown, the electroplating cage 1 includes a cage body 11 and an electroplating cage cathode conductor arranged on the cage body. The electroplating cage cathode conductor has a power transmission part arranged in the cage body for conductive connection with components in the cage body and arranged outside the cage body for The power-receiving part electrically connected to the cathode conductor of the drum is provided with an electroplating cage guide hole 113 which is connected to the cavity of the cage body and allows convection of the plating solution in the drum. The cage 11 includes a cage body 111 extending along the front-to-rear direction and cage covers 112 arranged at the front and rear ends of the cage body. In this embodiment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com