A snow pushing device for a high-speed snow removal vehicle

A snow removal and high-speed technology, applied in snow surface cleaning, construction, cleaning methods, etc., can solve the problems of inability to cope with impact force, uneven force on equipment, equipment deformation, etc., to improve work efficiency, ensure stability, uniform force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

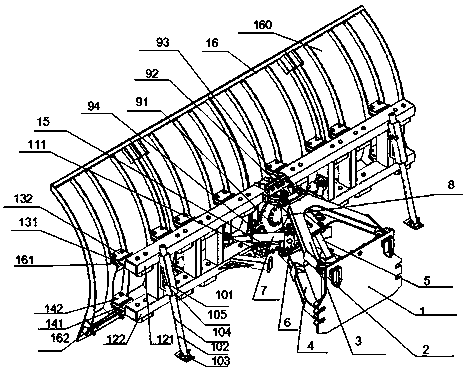

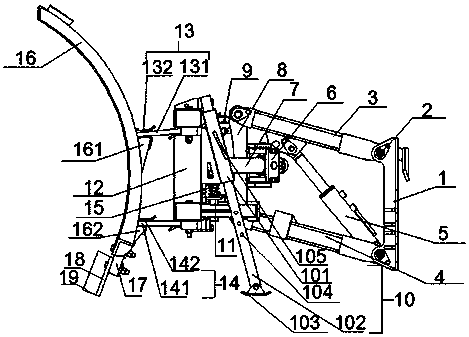

[0017] figure 1 and figure 2 A specific embodiment of the present invention is shown: a snow pushing device for a high-speed snow removal vehicle, including a vehicle-connected hanger 1, a steering seat 8, a main support frame 12, and a main board 16 of a snow pusher, and the connected vehicle hanger 1 and the steering seat 8 are provided with a suspension upper bracket 3 and a suspension lower bracket 4 arranged in parallel, one end of the suspension upper bracket 3 and the suspension lower bracket 4 are respectively hinged with the vehicle hanger 1, and the other ends are respectively hinged with the steering seat 8, so The inner wall of the linked vehicle hanger 1 is provided with a handle oil cylinder 5, the oil cylinder rod of the handle oil cylinder 5 is connected with the suspension upper bracket 3, and the first flexible buffer device 13 and the second flexible buffer device 13 are arranged on the main support frame 12. Flexible buffer device 14, the snow pusher main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com