Shed supporting roadway adjustable shield type hydraulic forepole supporting device

It is an adjustable technology of forward exploration support, which is applied in the direction of supporting the top beam of the mine roof, temporary shield, mining equipment, etc., and can solve the inconvenience of disassembly, head-on working surface side roof fall, and unstable fixation of the front exploration beam, etc. problems, to achieve the effect of convenient production, good support effect, and improved safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

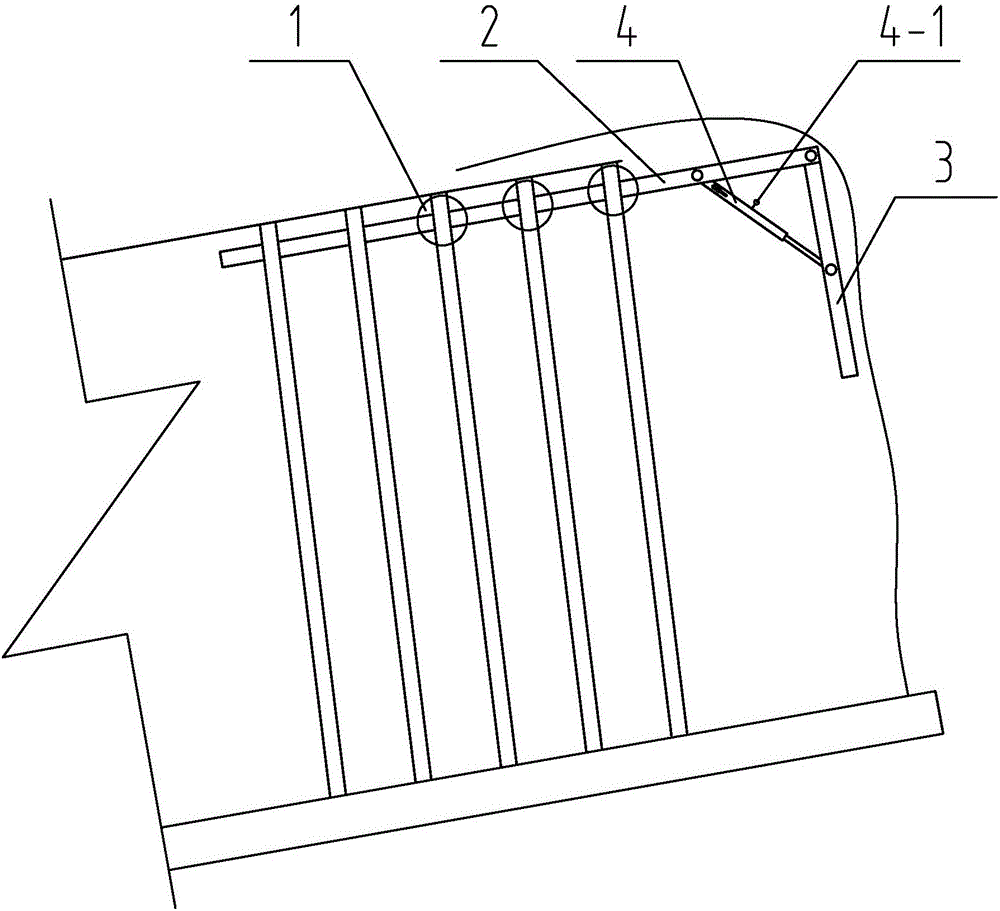

[0023] Specific implementation mode one: combine Figure 1 to Figure 4 To describe this embodiment,

[0024] The scaffolding support roadway can be adjusted to cover the hydraulic forward detection support device, including: the front detection beam fixer 1, the front detection beam 2, the support side beam 3 and the hydraulic prop 4;

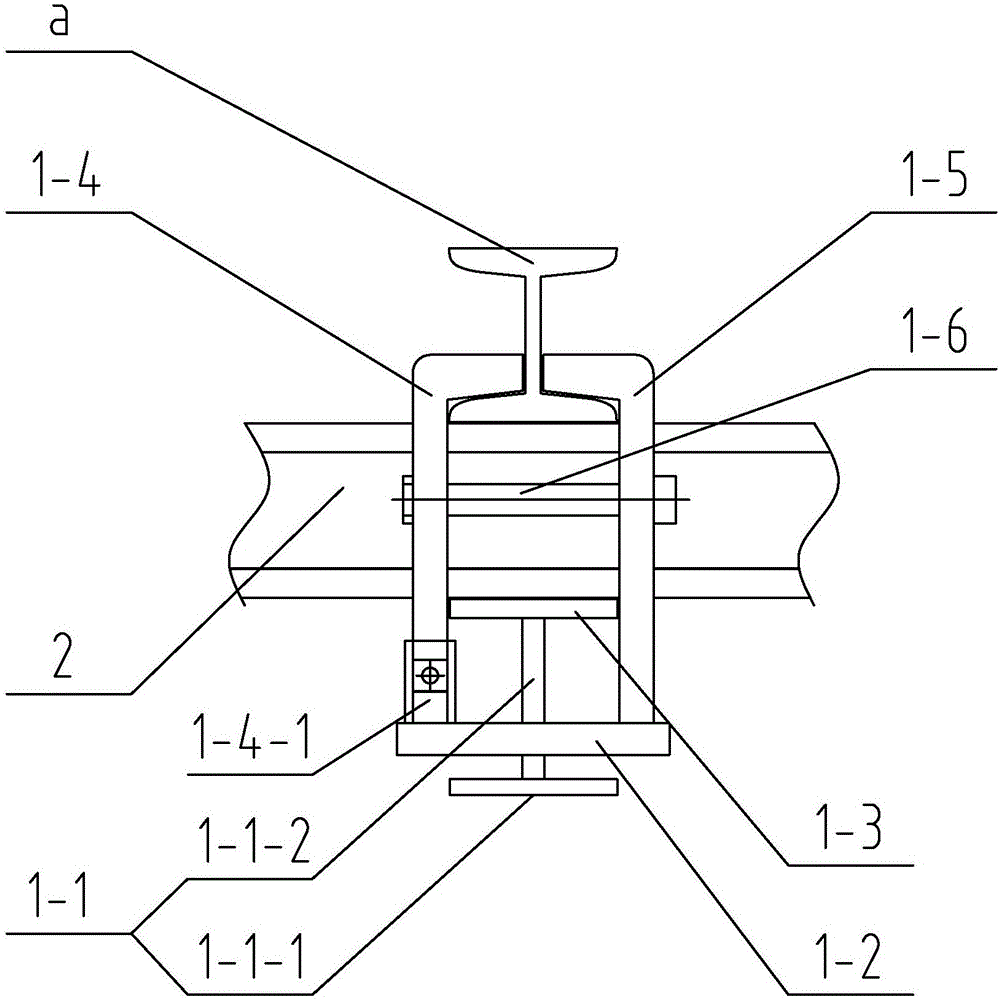

[0025] The front beam fixer 1 includes a rotary pressing device 1-1, a base 1-2, a screw pressing plate 1-3, two movable splints 1-4, two fixed splints 1-5, and two fixed splints. rods 1-6;

[0026] Two fixed splints 1-5 are fixed on the base 1-2; two movable splint connectors 1-4-1 are also provided on the base 1-2, and the two movable splint connectors 1-4-1 are respectively connected with two The lower ends of the movable splint 1-4 are connected by bolt rods, and the two movable splints 1-4 are respectively set corresponding to the two fixed splints 1-5; both the fixed splint 1-5 and the movable splint 1-4 are provided with fixing rod pas...

specific Embodiment approach 2

[0029] Specific implementation mode two: combination Figure 1 to Figure 2 To describe this embodiment,

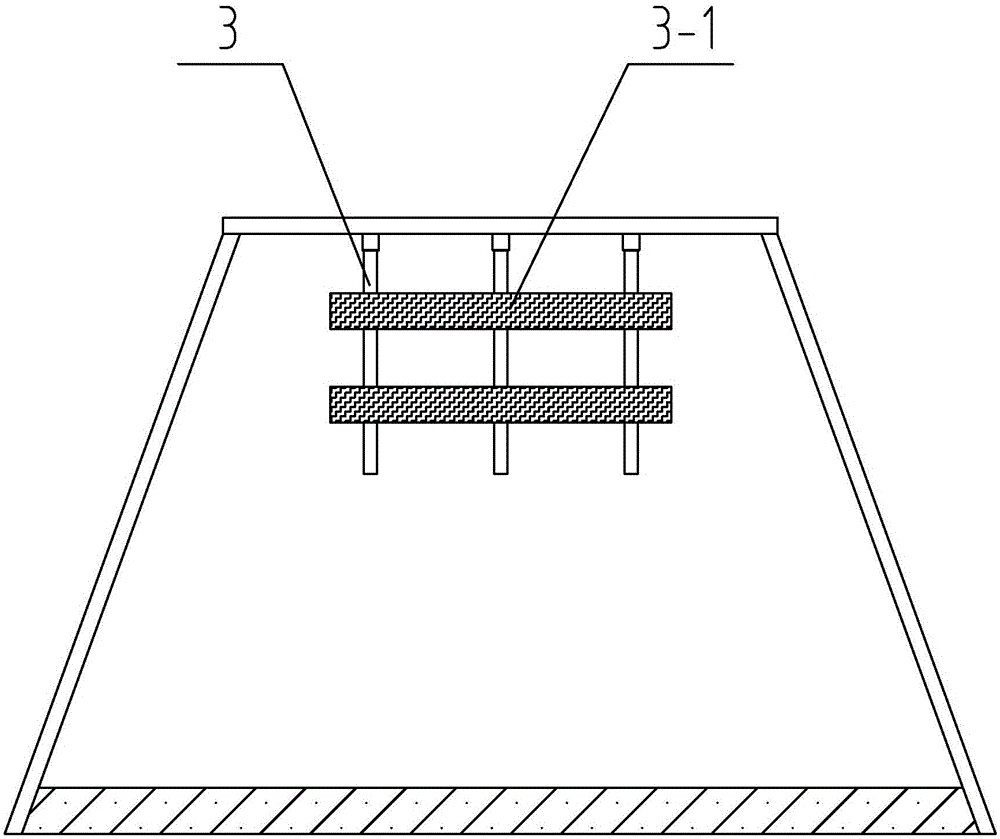

[0030] The support side beam 3 described in this embodiment is provided with a support side plate 3-1 on one side of the excavation work face, which plays the role of temporarily covering the head-on work face, and prevents the front and upper front of the excavation work face from being damaged as much as possible. The occurrence of film gang situation.

[0031] Other structures and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0032] The hydraulic prop 4 described in this embodiment is provided with a multifunctional explosion-proof pressure sensor 4-1, such as figure 1 shown.

[0033] Other structures and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com