Pre-separation system for positive-displacement air compressor

An air compressor and pre-separation technology, which is applied in the field of pre-separation systems, can solve the problems of frequent replacement and cleaning, the air filter cannot meet the requirements of filtering air, and is easily damaged, and achieves the effect of improving the screening efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

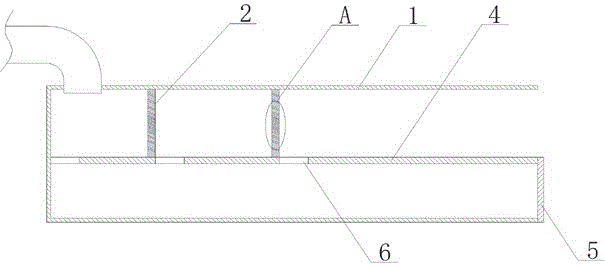

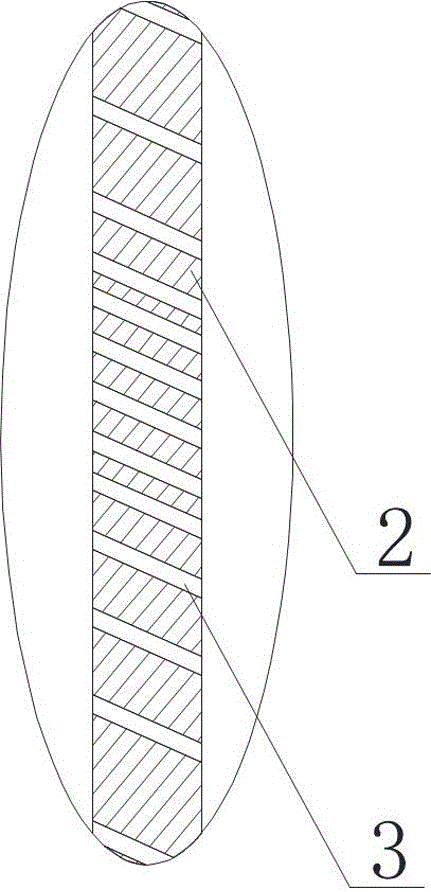

[0022] Such as figure 1 with figure 2As shown, the present invention is a pre-separation system for a volumetric air compressor, including a housing 1, one end of the housing 1 is a closed end, and the other end is an open end, and the top of the housing 1 is equipped with an exhaust pipe close to the closed end. The closed end of the shell 1 is provided with a partition 4 parallel to the horizontal plane, the partition 4 extends from the closed end of the shell 1 to the open end, and divides the inner space of the shell 1 into the air filter located above the partition 4 chamber, and the sand collection chamber below the partition 4, the sand collection chamber is located at one end of the open end of the shell 1 and is provided with a matching sand collection chamber cover 5, and above the partition 4 is provided with a channel plate 2 perpendicular to the partition 4, Several channels 3 are arranged on the channel plate 2 , and sand discharge holes 6 are arranged on the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com