Fan coil capable of being cleaned and disinfected without disassembling and cleaning and disinfecting method

A technology for cleaning and sterilizing fan coil units, which can be used in heating methods, space heating and ventilation, space heating and ventilation details, etc., and can solve the problems of easy falling off of insulation layer, condensation on the outer surface of the fan, and inconvenient disassembly and restoration. , to solve the volute water and water leakage, improve sewage capacity, clean and disinfect thoroughly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

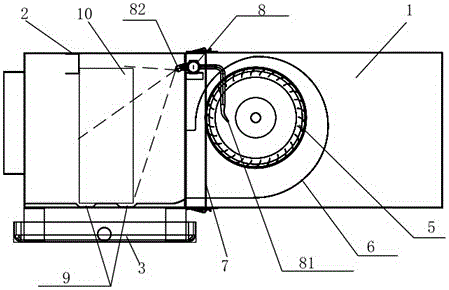

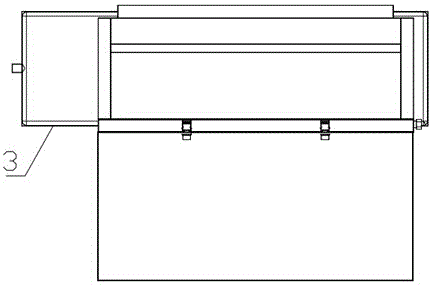

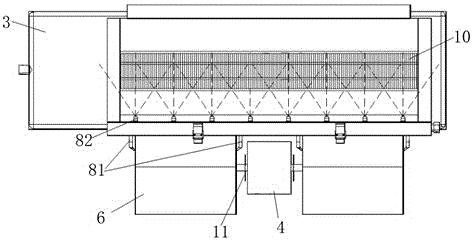

[0040] Such as Figure 1 to Figure 8 As shown, the present invention includes a return air box 1, a coil casing 2, a fan, and a condensate pan 3; a coil 10 is arranged in the coil casing 2, and the fan includes a motor 4, an impeller 5, a volute 6 and a fan bracket 7 It is characterized in that: the volute 6 is fixed on the fan bracket 7, the air outlet 61 of the volute 6 faces the coil 10, and is located at the lower part of the volute 6; the fan bracket 7 and the return air box 1 are connected by a connecting piece. In this embodiment, the hasp is preferably used as the connector, and the connecting edges of the fan bracket 7 and the return air box 1 are all folded inward to form a butt-jointed hem, and rubber and plastic sealing strips are installed in the middle of the hem to enhance the sealing effect. Under the pulling force of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com