In-situ preserving coring system and method

A fidelity and in-situ technology, applied in the field of in-situ mechanics of rock mass, can solve problems such as inability to reflect the mechanical properties of rock mass, and achieve the effect of easy device and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

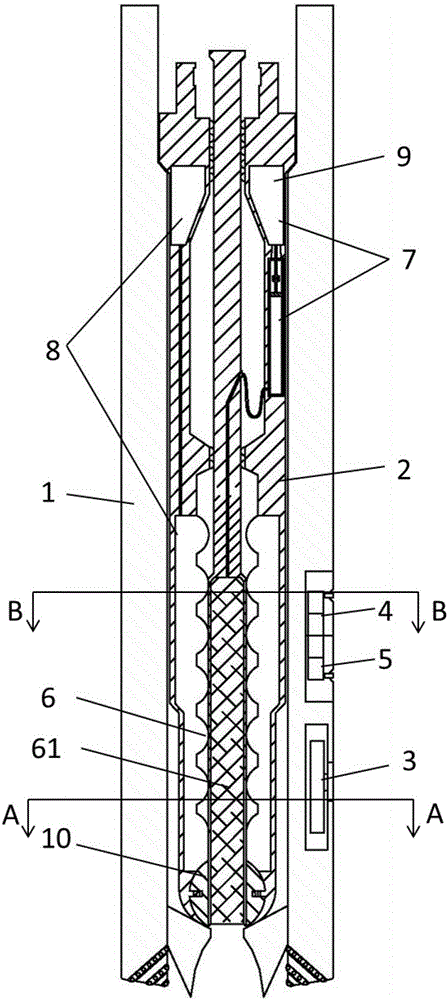

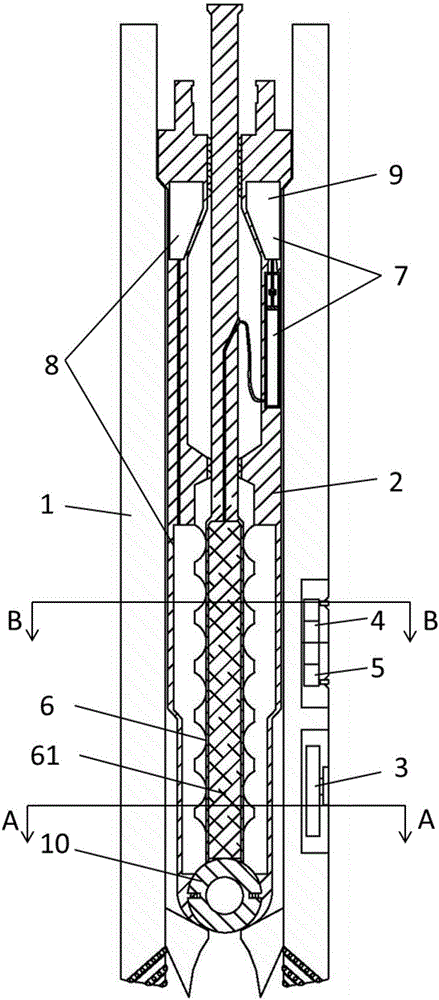

[0033] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

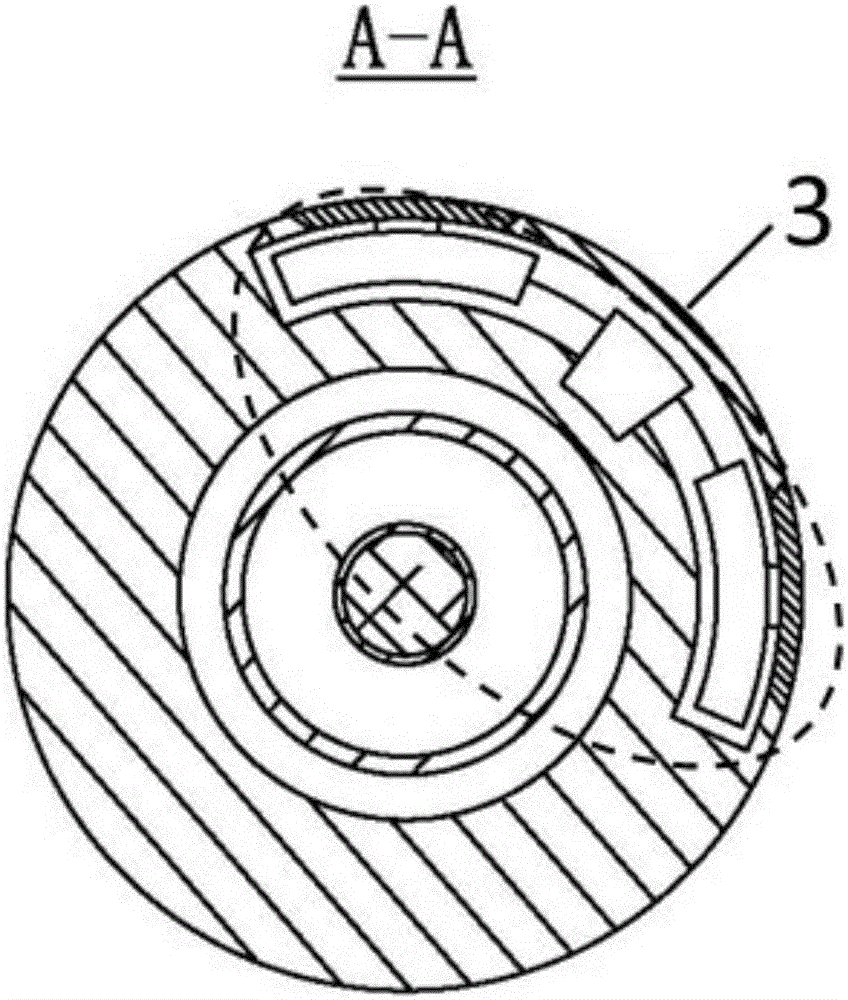

[0034] Such as Figure 1-4 As shown, the in-situ fidelity coring system of the present invention includes a core drilling tool 1 and a core fidelity equipment, and coring is to drill a rock core. The coring drilling tool 1 includes a drill bit and a drill connected to the upper end of the drill bit. The tool body, the drill bit and the drill body can be selected from existing rock-oriented drilling tools. A pressure test device 3 is arranged on the side wall of the drill tool body close to the drill bit, and a temperature test device 3 is arranged above the pressure test device 3. The device 4 and the humidity testing device 5 , in other words, the pressure testing device 3 is integrated near the drill bit of the core drilling tool 1 , and the temperature testing device 4 and the humidity testing device 5 are integrated on the core drilling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com