A self-compensating in-situ drilling coring and testing device

A testing device and self-compensating technology, applied in the direction of extraction of undisturbed cores, earthwork drilling, wellbore/well components, etc., can solve problems such as staying in conceptualization, achieve fidelity, save energy, save production and maintenance costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

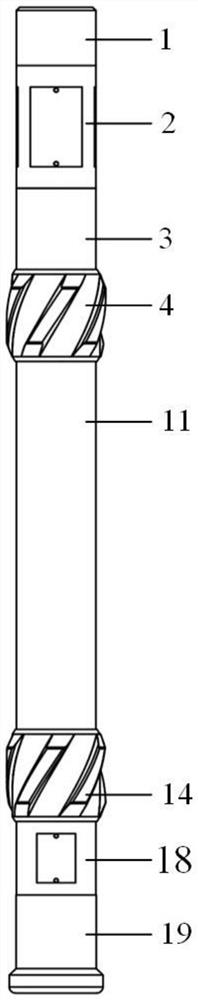

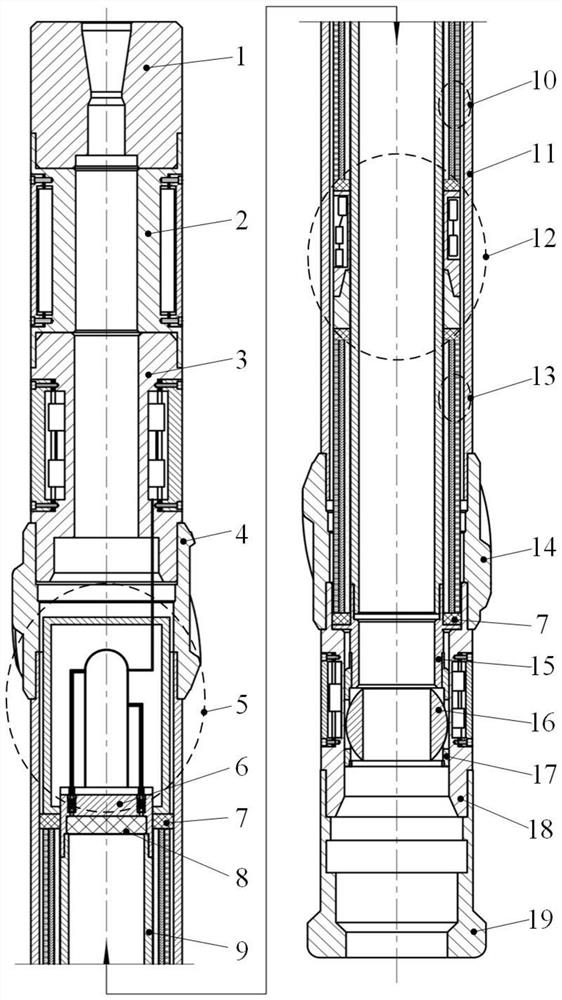

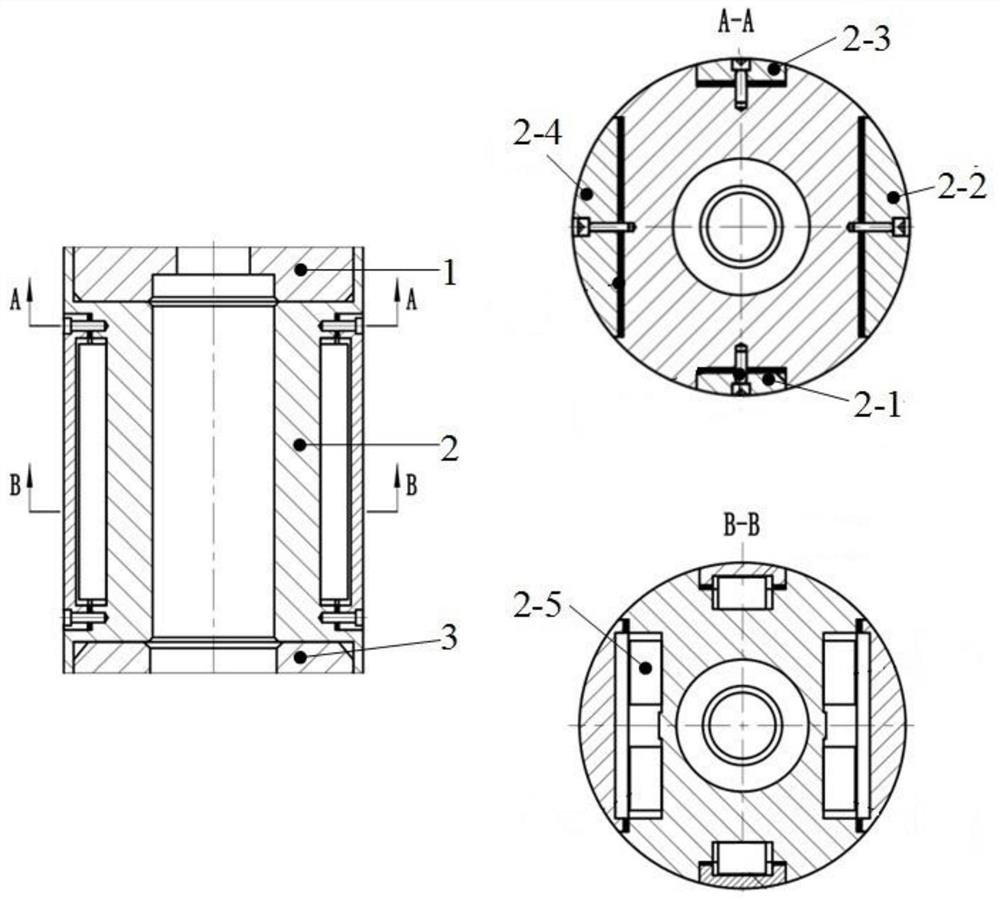

[0044] refer to figure 1 As shown, a self-compensating in-situ drilling coring and testing device includes a safety upper joint 1, a power supply base 2, a core control base 3, a first centering joint 4, and a fixed connection from top to bottom. Coring inner cylinder 9, coring outer cylinder 11, second centering joint 14, core measurement and control base 18, downhole coring bit 19; said core control base 3 is provided with a pressure temperature control device; correspondingly, the core measurement and control The inside of the base 18 is provided with a pressure and temperature measuring device and a ball valve opening and closing control device; the coring inner cylinder 9 is sleeved inside the coring outer cylinder 11, and the The upper section 10 of the heat preservation device and the lower section 13 of the heat preservation device are installed between the outer cylinders 11; a rock core deformation testing device 12 is arranged between the upper section 10 of the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com