A lake core sampling device for lake sediments with different water depths

A sampling device and sediment technology, applied in the direction of sampling devices, etc., can solve the problems of limited sampling range, low sampling success rate, disturbance, etc., and achieve the effect of improving sample integrity, improving sampling success rate, and increasing the depth of depression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

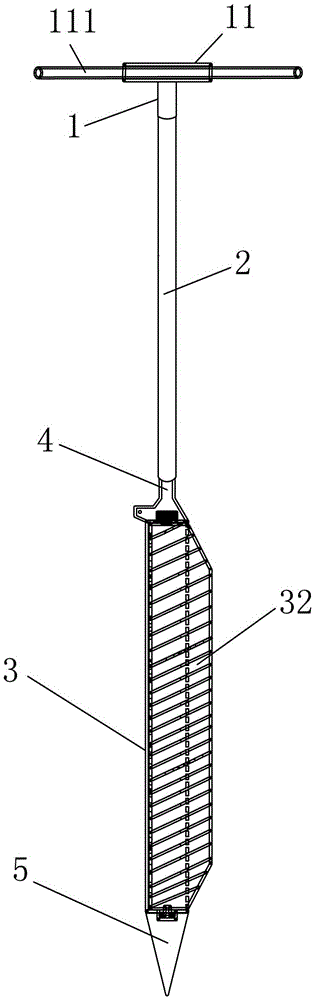

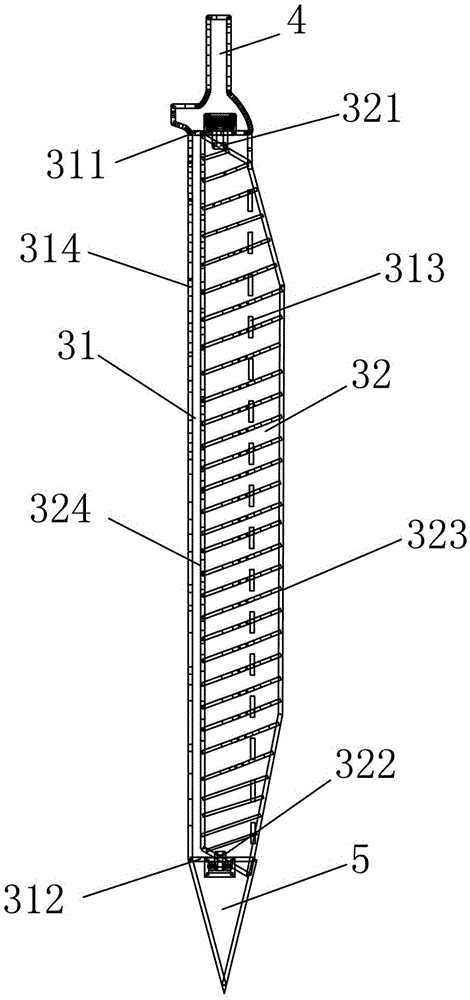

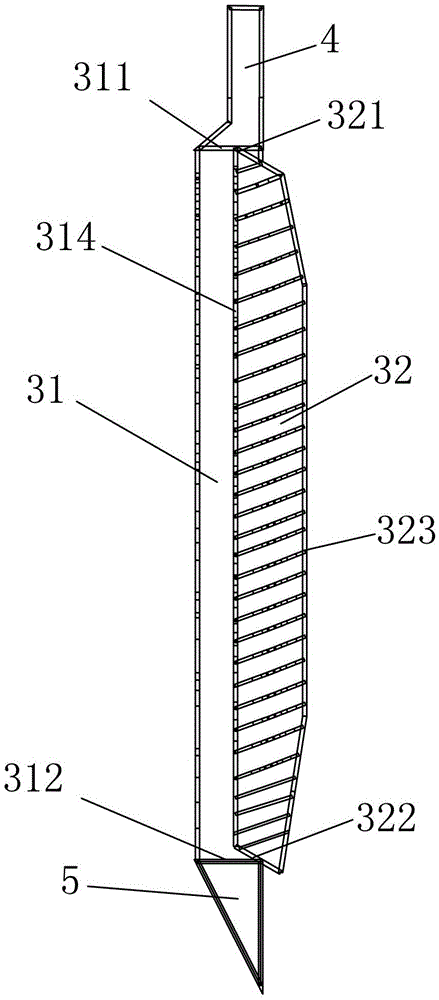

[0058] Such as Figures 1 to 4 As shown, a lake core sampling device for lake sediments with different water depths, the lake core sampling device includes a handle rod 1, a drill rod 2 and a rotary core catcher 3 fixedly connected by welding in sequence from top to bottom;

[0059] The rotary core catcher 3 includes a sample tube 31 and a rotary blade 32, the sample tube 31 body is a semicircular tank; the top 311 of the semicircular tank is provided with a Connecting rod 4, the outer surface of the bottom end 312 of the semicircular tank is fixed with a drill bit 5;

[0060] The two ends 321, 322 of the rotary blade 32 are respectively rotatably connected to the top end 311 and the bottom end 312 of the semicircular tank; one side 323 of the rotary blade 32 protrudes from the semicircular Outside the one side 313 of the arc-shaped wall of the tank body, the other side 324 of the rotary blade 32 is adjacent to the inner side wall 315 of the other side 314 of the arc-shaped w...

Embodiment 2

[0066] Such as Figures 5 to 8 As shown, the difference between this embodiment and Embodiment 1 is that: the handle rod 1 and the drill rod 2 are a sliding fit connection structure, that is, the drill rod 2 can slide in a matching manner in the handle rod 1; There is a first through hole 12, the drill rod 2 is provided with a first connecting hole 21, and the first through hole 12 and the first connecting hole 21 are fixed by bolts;

[0067] The purpose of this design is that the length of the lake core sampling device can be increased as required, which is beneficial to continuous depth lake core sampling.

[0068] The connecting rod 4 set on the top 311 of the semicircular tank body is sleeved in the drill rod 2, and the connecting rod 4 is provided with a second through hole 41, and the drill rod 2 is provided with a second through hole 41. The connection hole 22, the second through hole 41 and the second connection hole 22 are fixed by bolts.

[0069] Both connections a...

Embodiment 3

[0071] Such as Figure 9 , 10 As shown, the difference between this embodiment and Embodiment 1 is that: the drill pipe 2 is provided with a weight device, and the weight device includes a weight 6 sleeved on the drill pipe 2 and a weight fixed on the drill pipe 2. The bearing limit plate 61 on the rod 2 is used to bear the impact force of the weight 6 .

[0072] The lake core sampling device also includes a support frame 7, the top of the support frame 7 is provided with a pulley 71; the pulley 71 is provided with a steel wire rope 8, and one end 81 of the steel wire rope 8 is connected to the weight 6, The other end 82 of the wire rope 8 is a free end.

[0073] In this embodiment, for the structure of the lake core sampling device described in Embodiment 1, a heavy hammer device is added when sampling deep-water lakes. The heavy hammer 6 is a hollow concentric circle structure, which is sleeved on the drill pipe 2 and connected with one end 81 of a steel wire rope 8. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com