Test device for membrane adhesion fastness of membrane-coated air filter felt and test method

A testing device and fastness technology, which are applied in the field of testing devices for lamination fastness of film-coated air filter felts, to achieve the effects of ensuring air tightness, a simple structure and a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

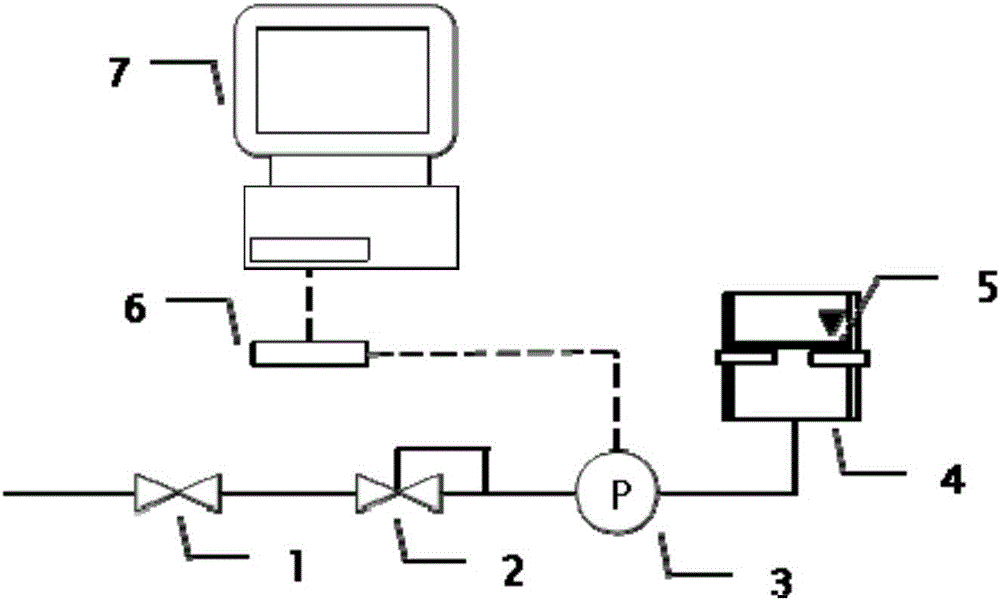

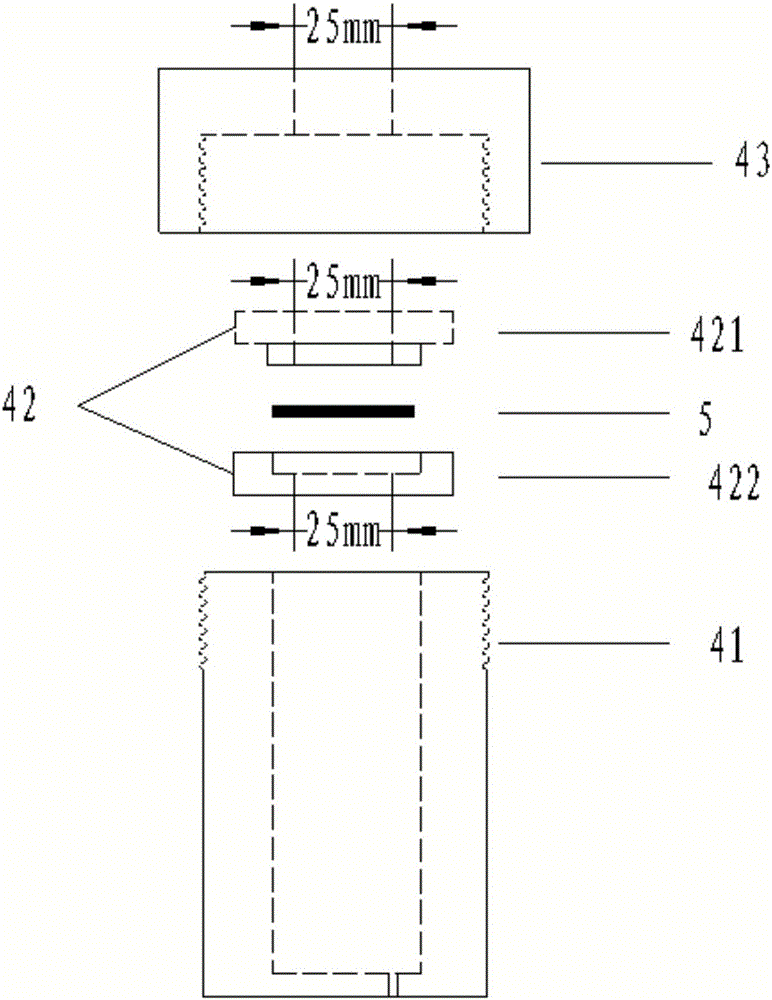

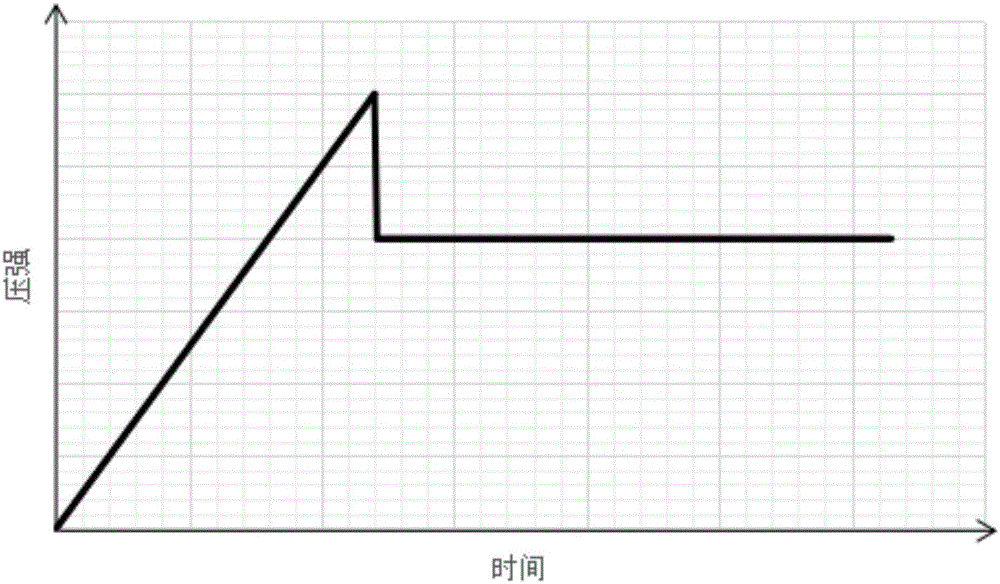

[0035] figure 1 It is a schematic diagram of the film lamination fastness test device. figure 2 It is a schematic diagram of the test chamber structure. Such as figure 1 As shown, the film bonding fastness testing device includes an air source switch 1, an air pressure regulating valve 2, a pressure sensor 3, a test chamber 4, a microprocessor 6 and a computer 7, the air source switch 1, the air pressure regulating valve 2, the pressure The sensor 3 and the test chamber 4 are connected in sequence through the air flow pipeline. The air source switch is used to control the delivery of air flow to the test chamber. The air pressure regulating valve is used to adjust the pressure of the air in the test cup. The pressure sensor 3 is used to detect the test chamber. The pressure sensor 3 is connected to the computer 7 through the microprocessor 6, and signals can be transmitted between the connections, and the computer 7 draws the signal received from the microprocessor 5 into a...

Embodiment 2

[0047] The test sample is 550g / m 2 The polyester fiber face layer is covered with a film air filter felt, and all the other procedures are the same as in Example 1. The test results obtained are as follows:

[0048] Sample 2: 550g / m 2 Polyester fiber surface layer coated air filter felt

[0049]

Embodiment 3

[0051] The test sample is 450g / m 2 The polyphenylene sulfide fiber surface layer is covered with a film air filter felt, and the rest of the procedures are the same as in Example 1. The test results obtained are as follows:

[0052] Sample 3: 450g / m 2 Polyphenylene sulfide fiber surface layer coated air filter felt

[0053]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap