Gas chromatograph for measuring solution gas in transformer oil

A technology of gas chromatograph and transformer oil, which is applied in the field of gas chromatograph, can solve the problems of long instrument stability time, increased analysis time, and failure to meet the detection limit requirements, and achieve the effect of convenient operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

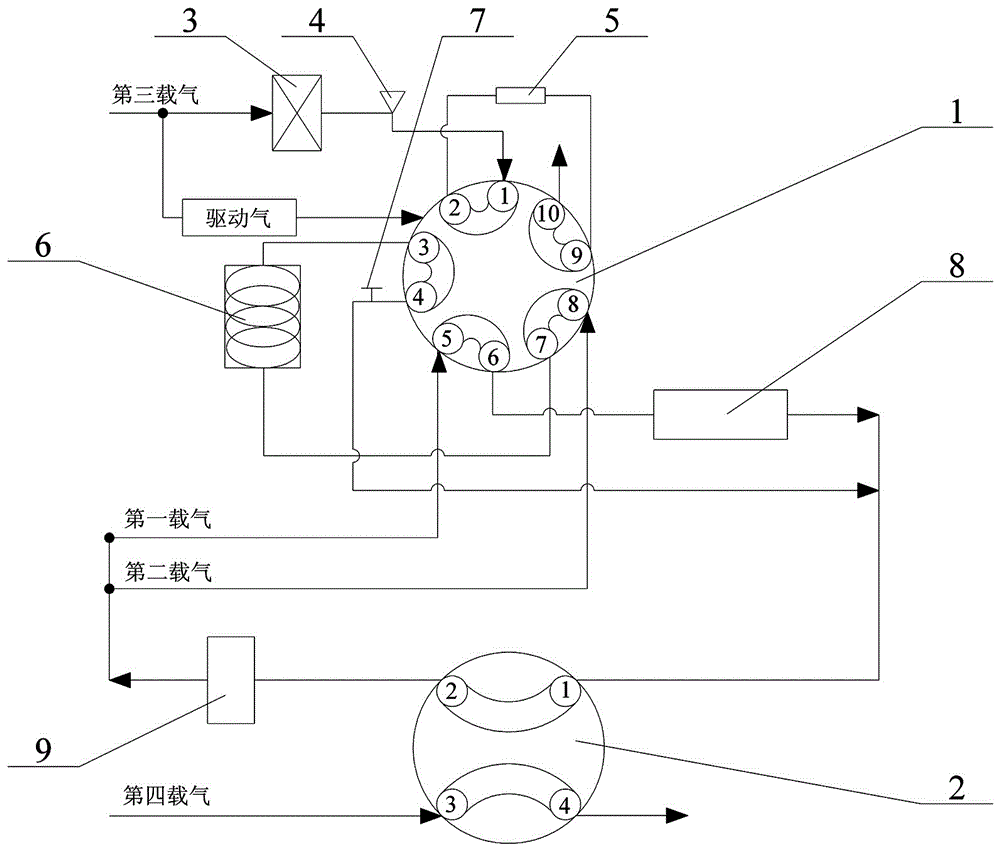

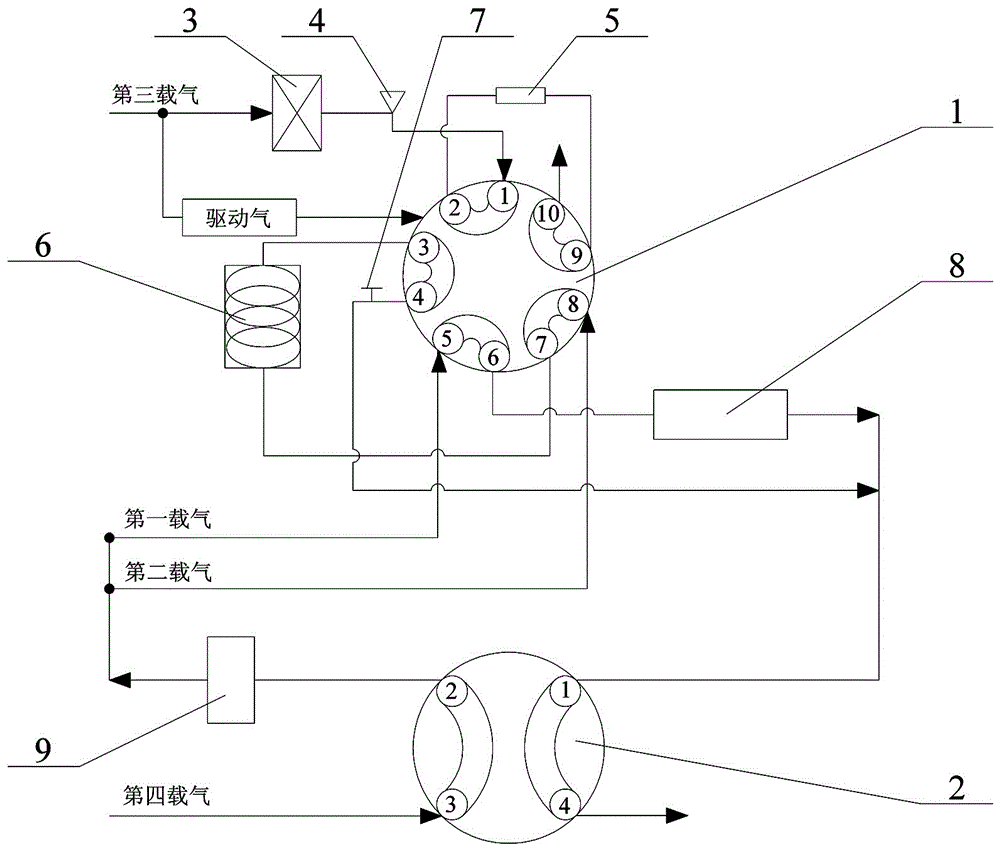

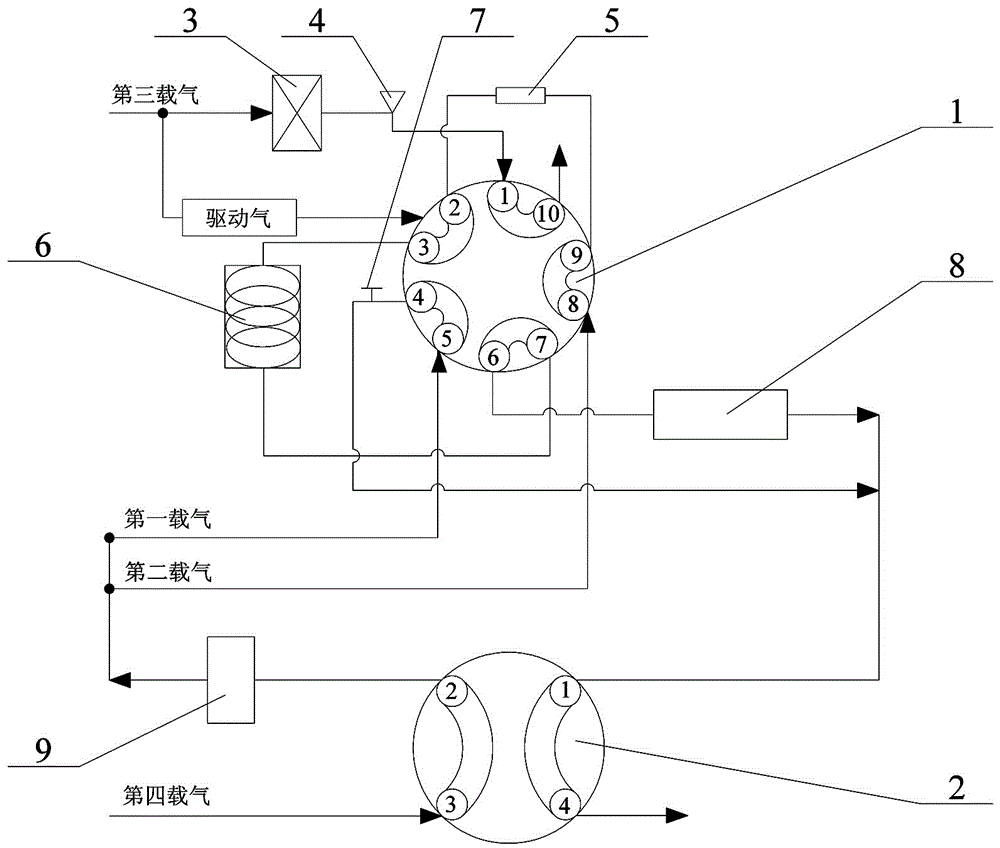

[0014] According to attached figure 1 , the present invention is a gas chromatograph for measuring dissolved gas in transformer oil, including residual sample gas self-cleaning system, C in transformer oil 3 + Component backflush system, instrument rapid stabilization system and a helium ionization detector (PDD detector)8. The residual sample gas self-cleaning system is provided with an electromagnetic switching valve 3 for controlling the flow rate of the carrier gas. C in the transformer oil mentioned 3 + The component backflushing system includes a ten-way valve 1 on which a quantitative tube 5 and a needle valve 7 are arranged, and the instrument rapid stabilization system includes a four-way valve 2 . The electromagnetic switching valve 3 is connected to the sample injector 4 and then connected to the ten-way valve 1, the helium ionization detector 8, and the four-way valve 2 in sequence. The electromagnetic switch valve 3 is provided with a time controller, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com