Universal industrial production information acquisition system and method

A technology of information collection and barcode information, applied in the field of electronic information, to achieve the effect of easy upgrade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

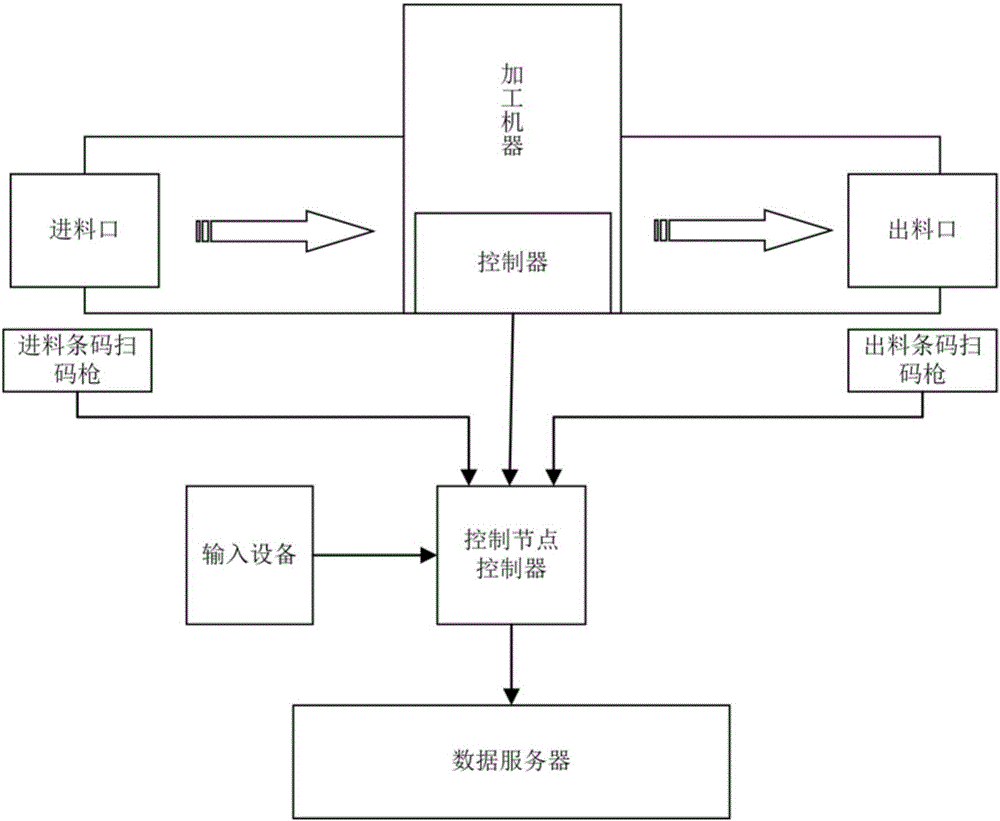

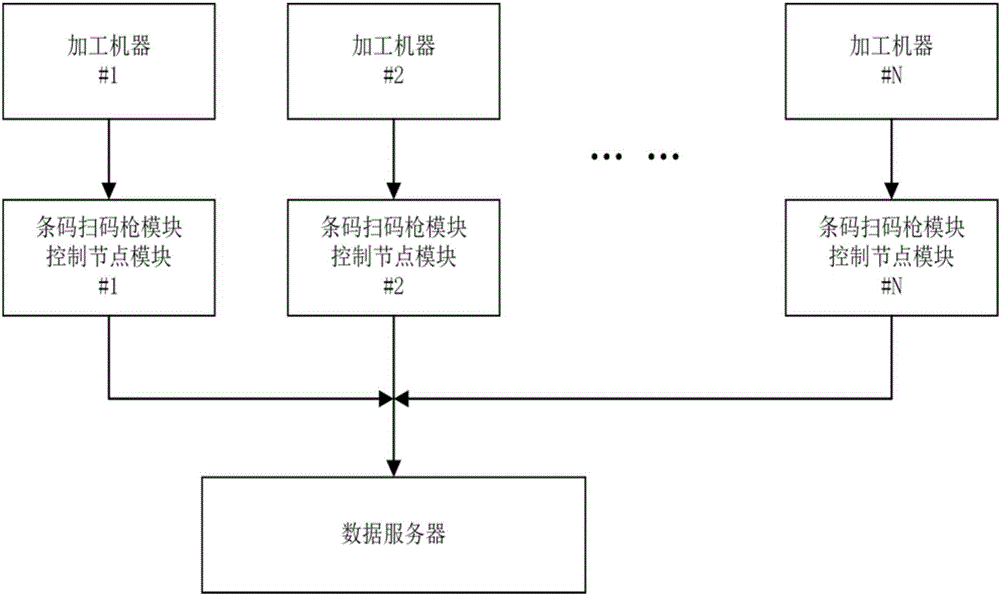

Embodiment 1

[0040] This embodiment provides a general industrial production information collection system, including multiple incoming and outgoing barcode scanning gun modules, multiple control node modules and a data server module, each incoming and outgoing barcode scanning gun module corresponds to a control node module , the multiple control node modules are all connected to the data server module; the incoming and outgoing barcode scanning gun module is used to scan the barcodes on the raw materials in the feed inlet and outlet of the processing machine in real time and upload the barcode information obtained by scanning To the control node module, the control node module is used to receive the barcode information uploaded by the incoming and outgoing barcode scanning gun module, and collect the processing parameters of the processing machine connected to it in real time, generate a time stamp, upload the collected barcode information, and process the machine The processing parameter...

Embodiment 2

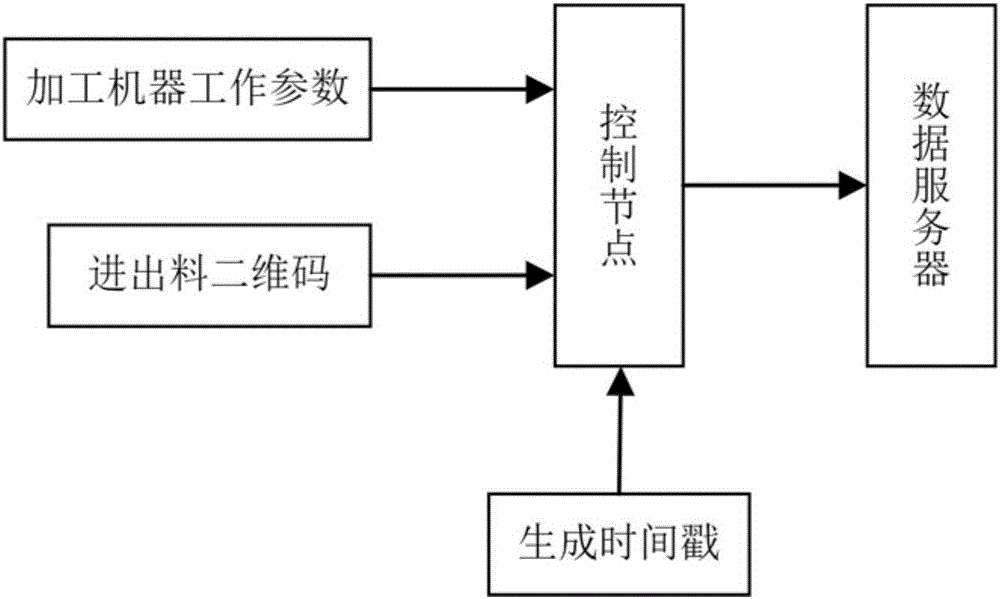

[0048] This embodiment provides a general industrial production information collection method, the method comprising the following steps:

[0049] Step 1. Before the production raw material enters the first processing node, paste the sticky barcode directly on the raw material box. The barcode uniquely corresponds to the processing raw material, which is called the ID of the raw material;

[0050] Step 2. When the production raw materials or semi-finished products enter or leave each processing node, the incoming and outgoing barcode scanning gun module automatically scans to obtain the ID of the raw material, and uploads it to the control node module in real time, and the control node module receives and stores the ID information of the raw material;

[0051] Step 3. Whenever raw materials or semi-finished products enter a processing node, the control node module corresponding to the processing node obtains the current processing parameters of the processing machine and genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com