based on mgb 4 Magnesium diffusion preparation method of precursor powder magnesium diboride superconducting wire

A magnesium diboride and superconducting wire technology, which is applied in the usage of superconductor elements, cable/conductor manufacturing, superconducting devices, etc., can solve the problems of immaturity and the decrease of engineering critical current density, and achieve high density, The effect of increasing the engineering critical current density and increasing the superconducting phase filling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

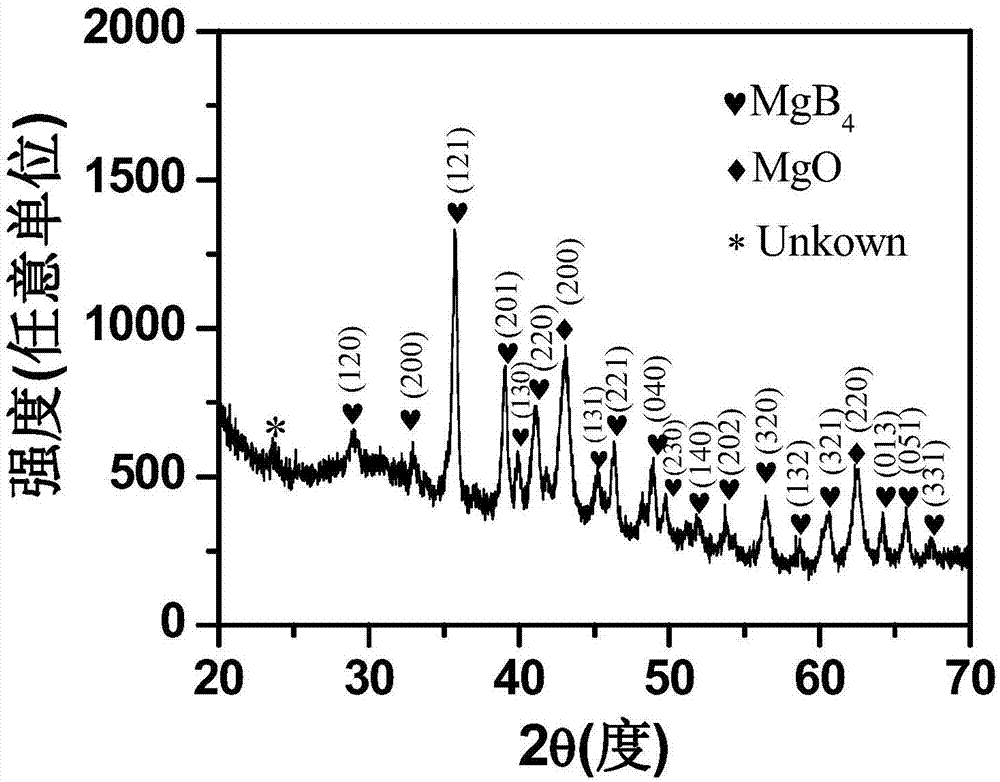

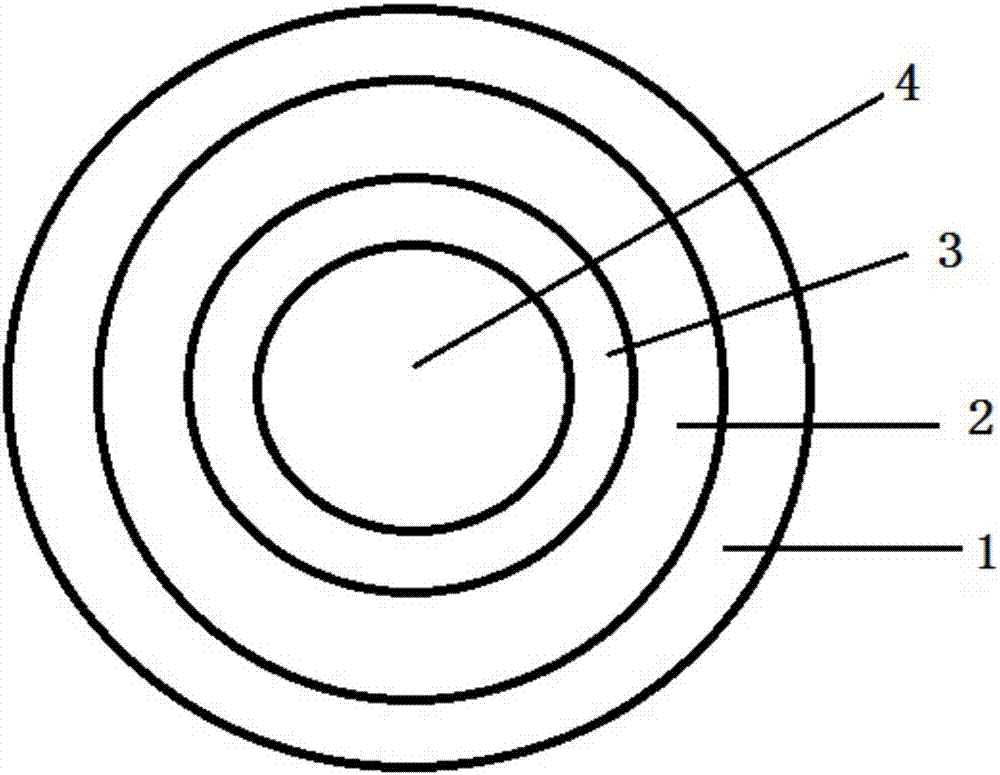

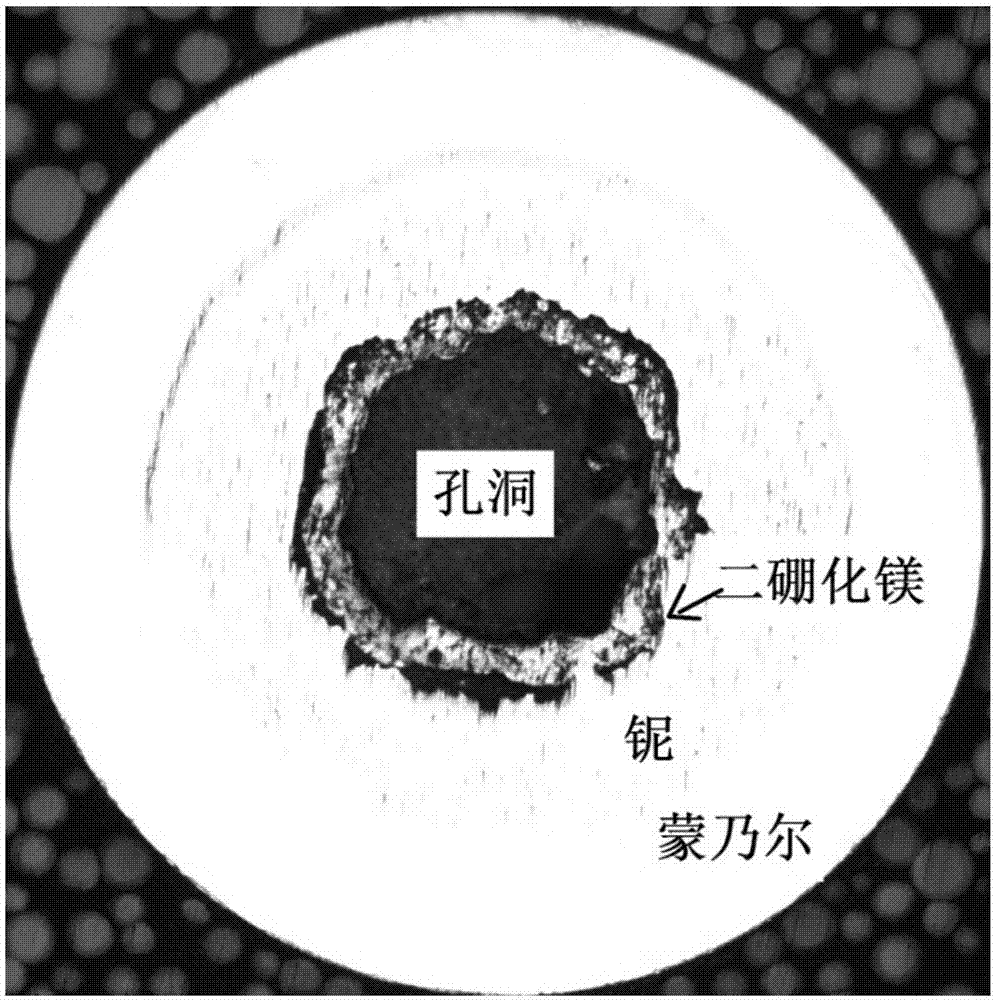

[0030] Step 1. According to MgB 2 MgB in wire preparation process 4 Magnesium, boron and carbon molar ratios required for powder generation Weigh magnesium powder, amorphous boron powder and nano-carbon powder into a ball mill and mix them, and then mix them according to MgB 2 MgB in wire preparation process 4 The mass ratio of raw materials and grinding balls required for powder generation is put into the grinding balls, and finally the ball mill tank containing the raw materials and grinding balls is sealed and fixed to the planetary ball mill, according to MgB 2 MgB in wire preparation process 4 The ball milling rate and ball milling time required for powder generation are used for ball milling the raw material mixed powder, and after the ball milling, the grinding balls are screened out to obtain the raw material mixed powder after ball milling;

[0031] The purity of magnesium powder is 95%, the particle size is 5μm, the purity of amorphous boron powder is 95%, the par...

Embodiment 2

[0045] Step 1. According to MgB 2 MgB in wire preparation process 4 Magnesium, boron and carbon molar ratios required for powder generation Weigh magnesium powder, amorphous boron powder and nano-carbon powder into a ball mill and mix them, and then mix them according to MgB 2 MgB in wire preparation process 4 The mass ratio of raw materials and grinding balls required for powder generation is put into the grinding balls, and finally the ball mill tank containing the raw materials and grinding balls is sealed and fixed to the planetary ball mill, according to MgB 2 MgB in wire preparation process 4 The ball milling rate and ball milling time required for powder generation are used for ball milling the raw material mixed powder, and after the ball milling, the grinding balls are screened out to obtain the raw material mixed powder after ball milling;

[0046] The purity of magnesium powder is 99%, the particle size is 10μm, the purity of amorphous boron powder is 98.5%, the ...

Embodiment 3

[0060] Step 1. According to MgB 2 MgB in wire preparation process 4 Magnesium, boron and carbon molar ratios required for powder generation Weigh magnesium powder, amorphous boron powder and nano-carbon powder into a ball mill and mix them, and then mix them according to MgB 2 MgB in wire preparation process 4 The mass ratio of raw materials and grinding balls required for powder generation is put into the grinding balls, and finally the ball mill tank containing the raw materials and grinding balls is sealed and fixed to the planetary ball mill, according to MgB 2 MgB in wire preparation process 4 The ball milling rate and ball milling time required for powder generation are used for ball milling the raw material mixed powder, and after the ball milling, the grinding balls are screened out to obtain the raw material mixed powder after ball milling;

[0061] The purity of magnesium powder is 99.8%, the particle size is 20μm, the purity of amorphous boron powder is 98.5%, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com