Safety socket

A technology of safety sockets and sockets, which is applied in the direction of the base/housing, electrical components, coupling devices, etc., can solve the problems of potential safety hazards in the use of sockets, unreasonable socket insertion settings, etc., to achieve increased quantity, tight combination, and increased quantity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

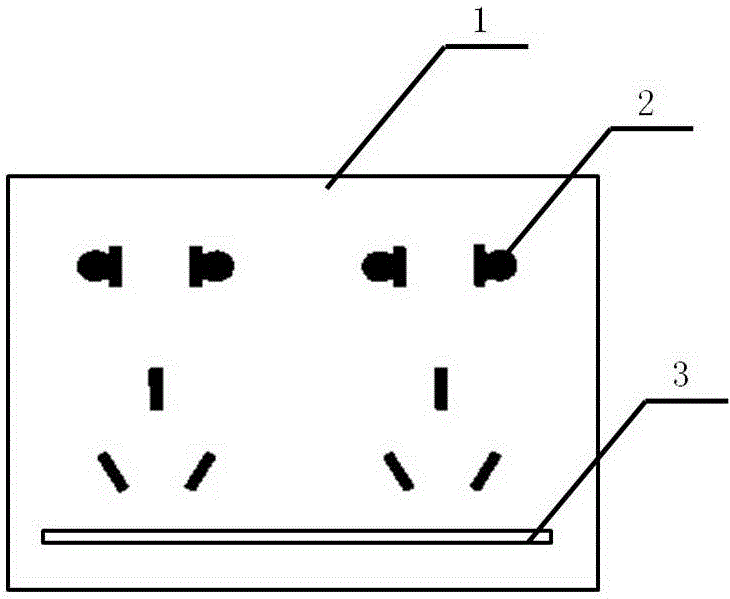

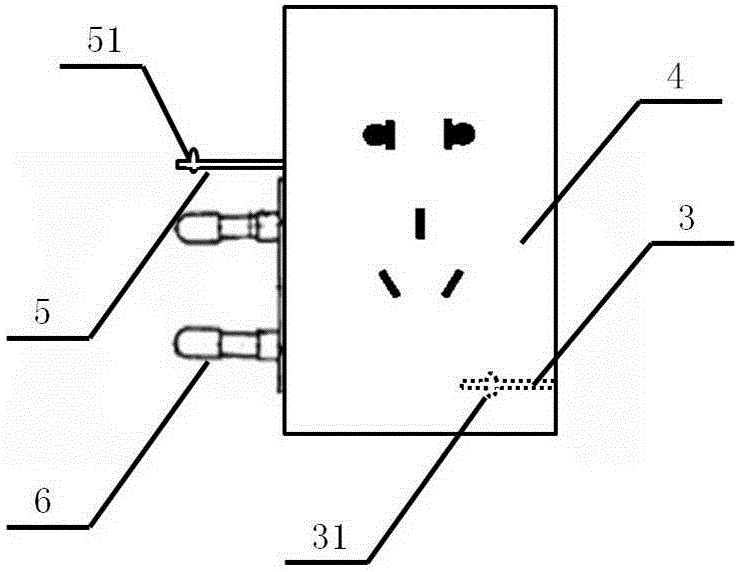

[0031] This embodiment provides a safety socket, including a wall socket 1 and a socket, such as Figure 1 to Figure 3 As shown, among them,

[0032] The wall socket 1 includes a socket 2 and a groove 3;

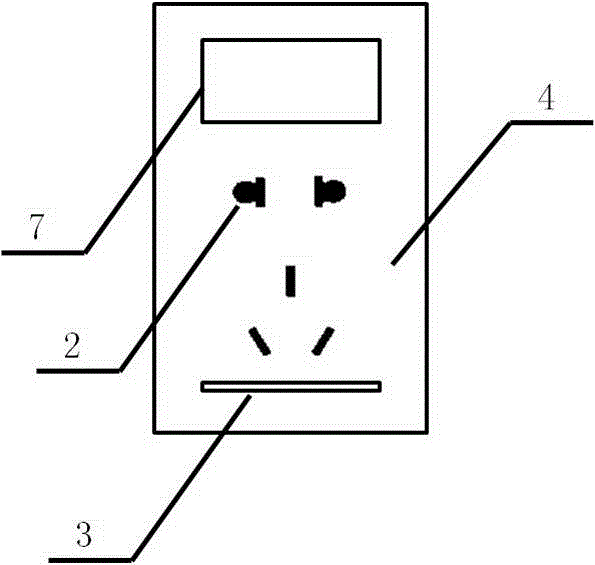

[0033] The plug strip is composed of more than two sockets 4, and the socket 4 includes a housing, a power plug 6, a socket 2, an LED display 7 and a warning light 8;

[0034] The shell of the socket 4 is a hexahedron, one side is provided with a power plug 6 and a fixed plate 5 connected to an external power supply, and the other five faces are provided with sockets 2 connected to electrical equipment, and the socket 2 on the opposite side of the power plug 6 One side of the socket 2 is provided with an LED display 7, and the other side is provided with a groove 3;

[0035] The distance between the groove 3 and the socket 2 is adapted to the distance between the fixed plate 5 and the socket 2;

[0036] The side of the fixing plate 5 is provided with a protrusion 51, and ...

Embodiment 2

[0041] This embodiment provides a safety socket, including a wall socket 1 and a socket, such as Figure 1 to Figure 3 As shown, among them,

[0042] The wall socket 1 includes a socket 2 and a groove 3;

[0043] The plug strip is composed of more than two sockets 4, and the socket 4 includes a housing, a power plug 6, a socket 2, an LED display 7 and a warning light 8;

[0044] The shell of the socket 4 is a hexahedron, one side is provided with a power plug 6 and a fixed plate 5 connected to an external power supply, and the other five faces are provided with sockets 2 connected to electrical equipment, and the socket 2 on the opposite side of the power plug 6 One side of the socket 2 is provided with an LED display 7, and the other side is provided with a groove 3;

[0045] The distance between the groove 3 and the socket 2 is adapted to the distance between the fixed plate 5 and the socket 2;

[0046] The side of the fixing plate 5 is provided with a protrusion 51, and ...

Embodiment 3

[0051] This embodiment provides a safety socket, including a wall socket 1 and a socket, such as Figure 1 to Figure 3 As shown, among them,

[0052] The wall socket 1 includes a socket 2 and a groove 3;

[0053] The plug strip is composed of more than two sockets 4, and the socket 4 includes a housing, a power plug 6, a socket 2, an LED display 7 and a warning light 8;

[0054] The shell of the socket 4 is a hexahedron, one side is provided with a power plug 6 and a fixed plate 5 connected to an external power supply, and the other five faces are provided with sockets 2 connected to electrical equipment, and the socket 2 on the opposite side of the power plug 6 One side of the socket 2 is provided with an LED display 7, and the other side is provided with a groove 3;

[0055] The distance between the groove 3 and the socket 2 is adapted to the distance between the fixed plate 5 and the socket 2;

[0056] The side of the fixing plate 5 is provided with a protrusion 51, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com