A bistable electro-hydraulic directional valve

An electro-hydraulic reversing valve, bistable technology, applied in fluid pressure actuating devices, servo motor components, mechanical equipment, etc. The steady state is highly reliable, the response speed is improved, and the weight of the spool is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

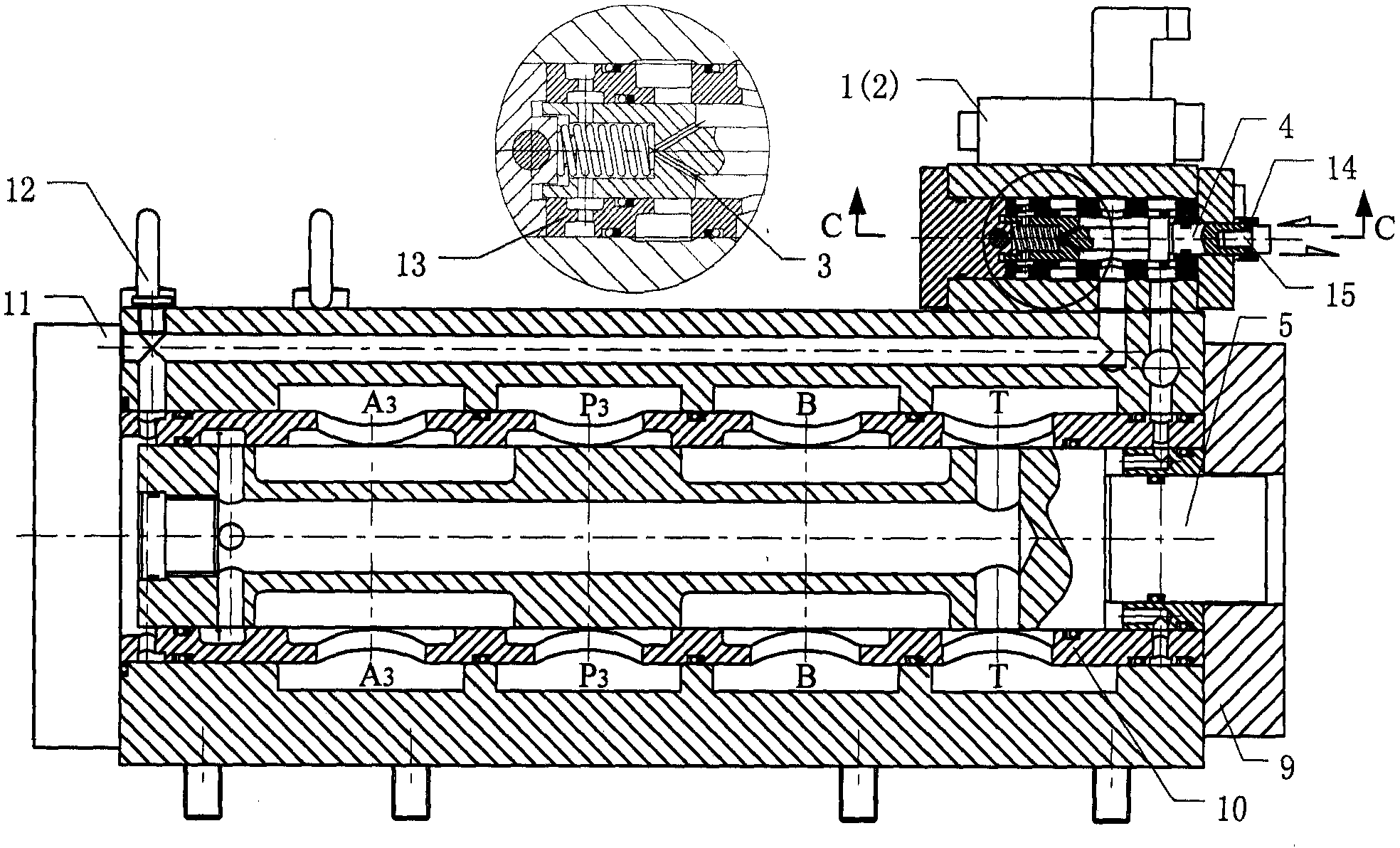

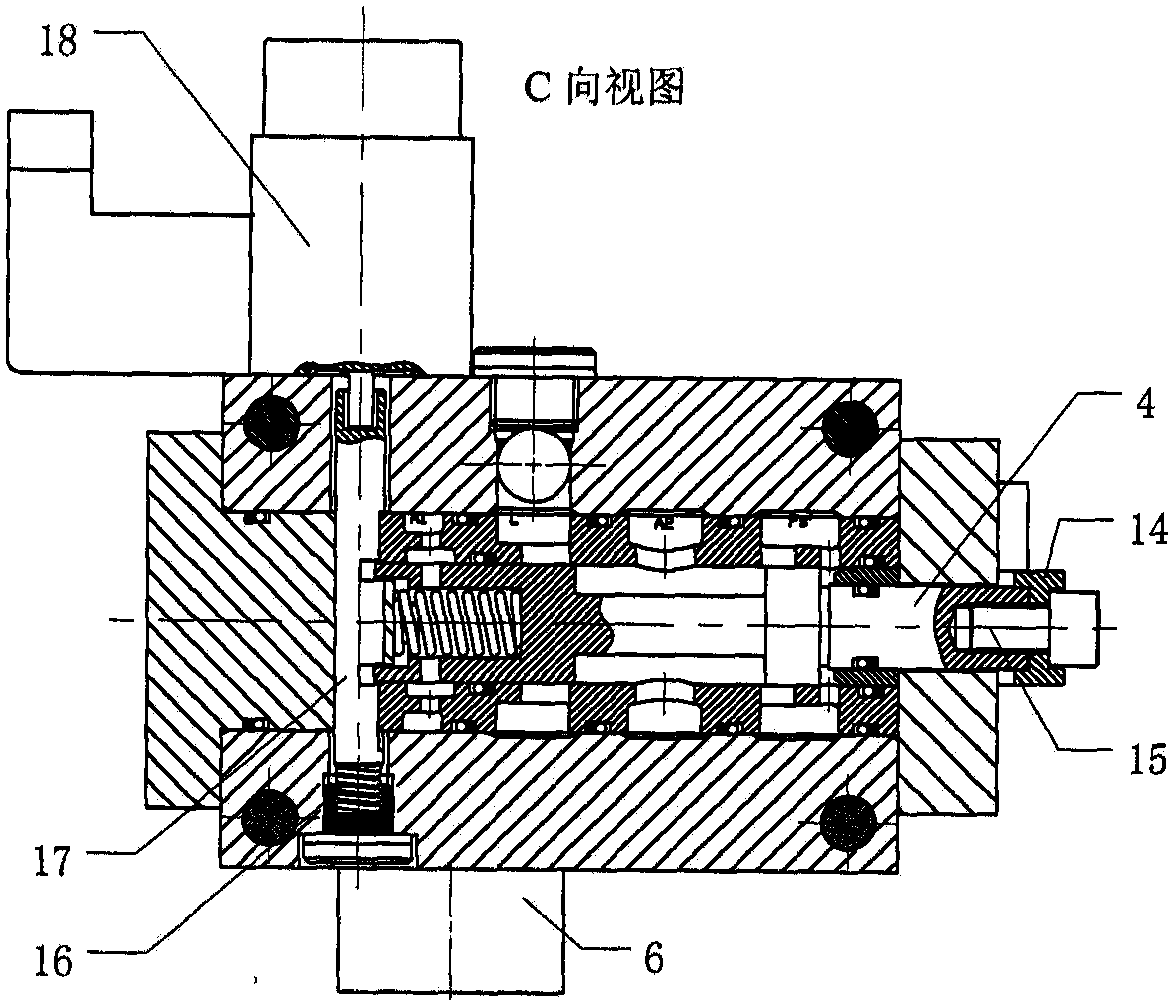

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

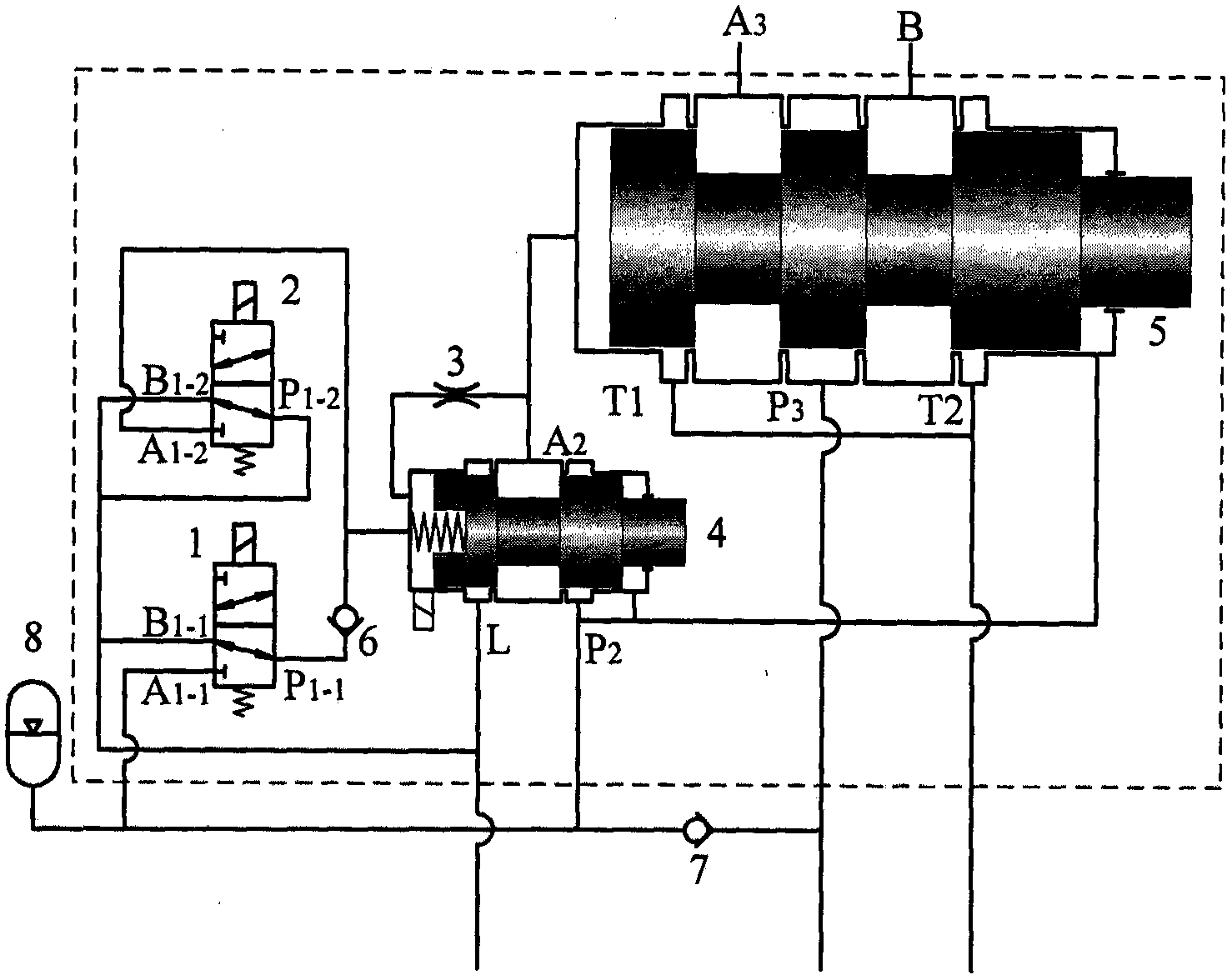

[0019] like figure 1 As shown, a bistable electro-hydraulic reversing valve of the present invention includes pilot valve one 1, pilot valve two 2, orifice 3, two-stage valve, three-stage valve, one-way valve one-6, one-way valve Two 7 and accumulator 8.

[0020] The two-stage valve includes a two-stage valve cavity and a two-stage valve spool 4, and the two-stage valve cavity is divided into a left-end valve cavity from left to right by the valve cavity wall and the boss on the valve cavity wall. , middle left valve cavity, middle valve cavity, middle right valve cavity and right end valve cavity, the secondary valve spool 4 has two shoulders, the left end surface area of the secondary valve spool 4 is greater than its right end surface area , between the left end of the secondary valve spool 4 and the left end wall of the secondary valve cavity, a return spring t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com