Automatic dropping device

A dripping and automatic technology, applied in baking, dough cutting machinery, food science, etc., can solve the problems of inconsistent biscuit size, inconsistent dripping amount, etc., and achieve the effect of easy packaging and better appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

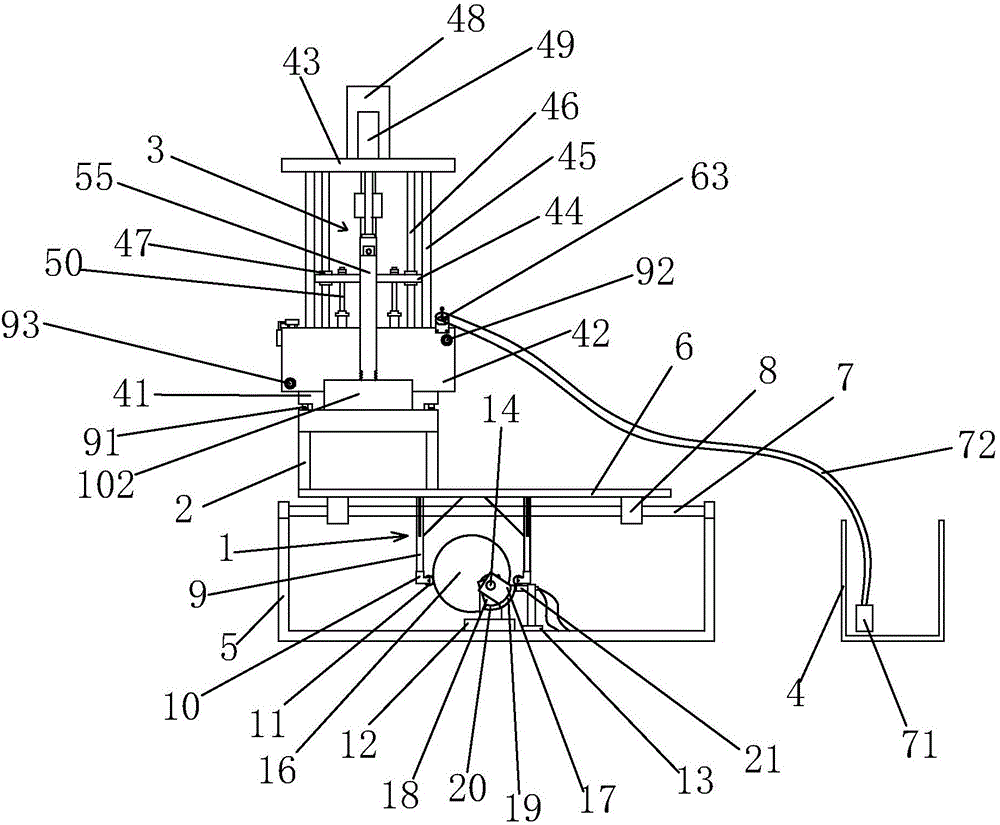

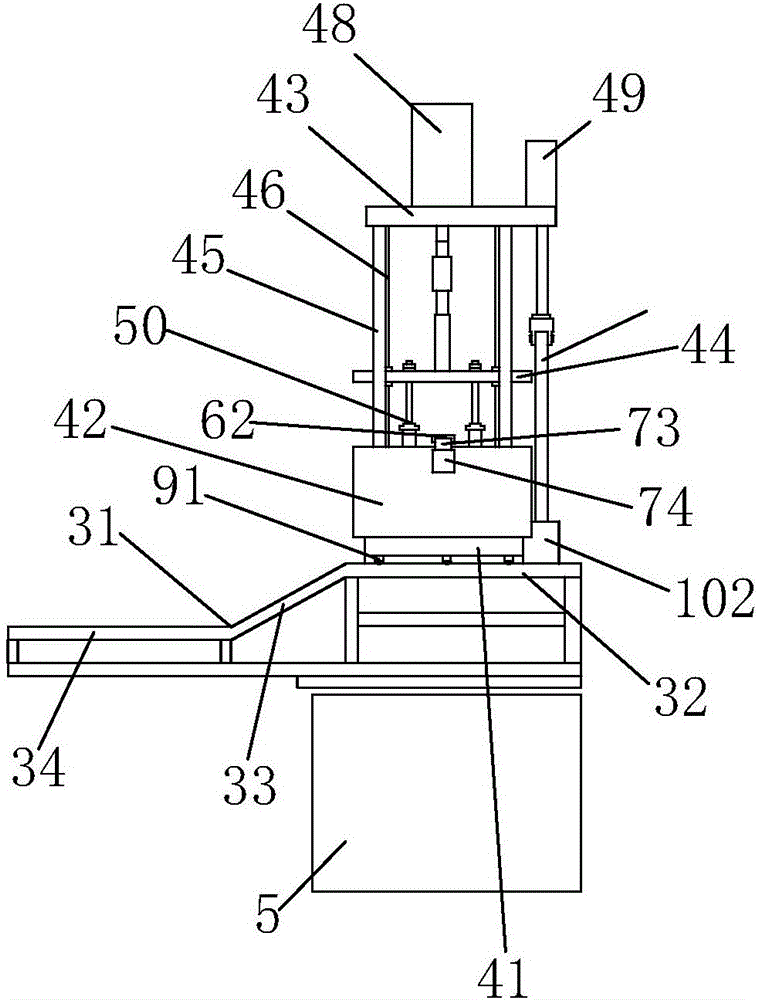

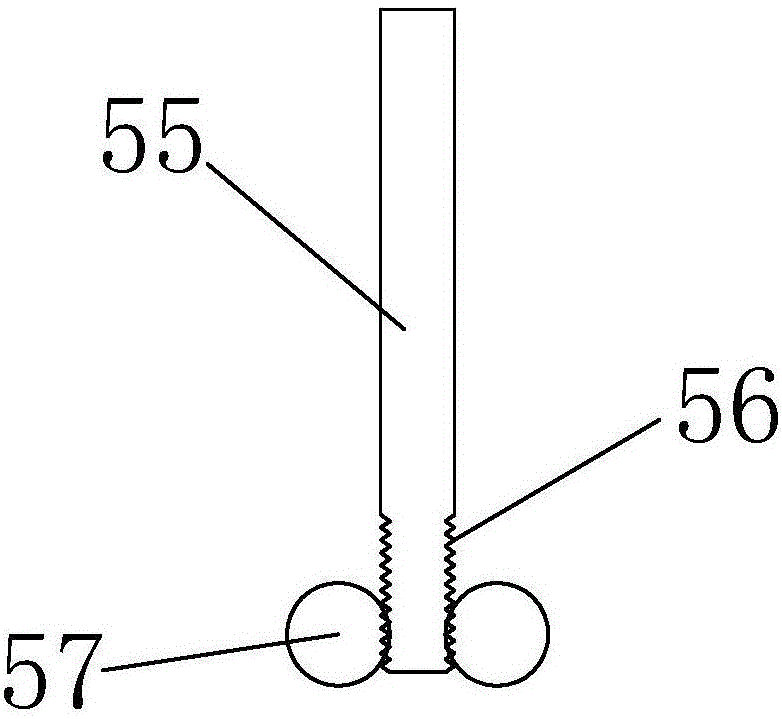

[0031] Such as Figure 1-7 As shown, an automatic dripping device includes a reciprocating device 1, a base 2, a uniform dripping device 3, and a bucket 4. The reciprocating device includes a concave-shaped base 5, a horizontal plate 6, and a concave-shaped base 5 Guide rails 7 are arranged between the two sides of the horizontal plate 6. Sliders 8 are arranged on both sides of the lower surface of the horizontal plate 6. The slider 8 is arranged on the guide rail 7. Two brackets 9 are also provided on the lower surface of the horizontal plate 6. The connecting seat 10 is provided with a guide wheel 11; the concave base 5 is provided with a fixed seat A12 and a fixed seat B13, the fixed seat A12 is provided with a rotating shaft A14, and the end of the rotating shaft A14 is connected with a motor that drives the rotating shaft A14 to rotate 15. An eccentric wheel 16, a turning block A17, and a turning block B18 are arranged on the rotating shaft A14. The eccentric wheel 16 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com