Composite material element for nylon hook-and-loop fastener and method for forming composite material element of hook-and-loop fastener

A composite material and Velcro technology, which is applied to the composite material elements constituting the Velcro and the composite material elements of the diaper buckle, can solve the problems of large unit area weight, high manufacturing cost and the like, and achieve the effect of simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

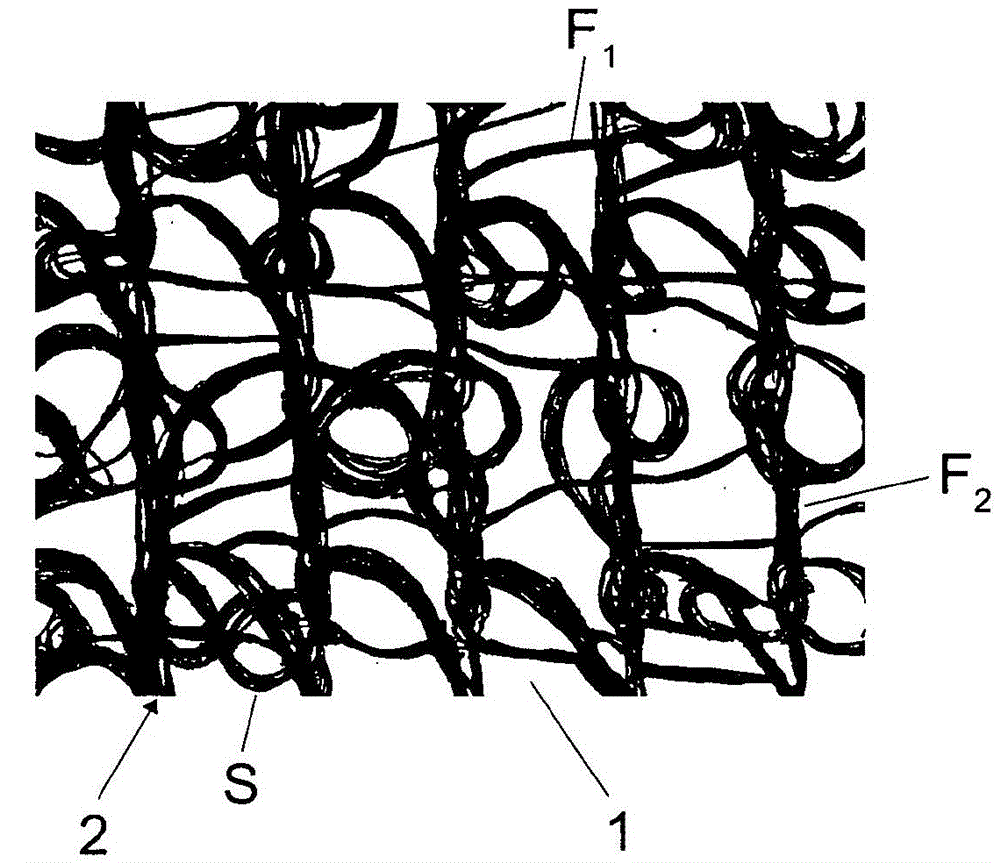

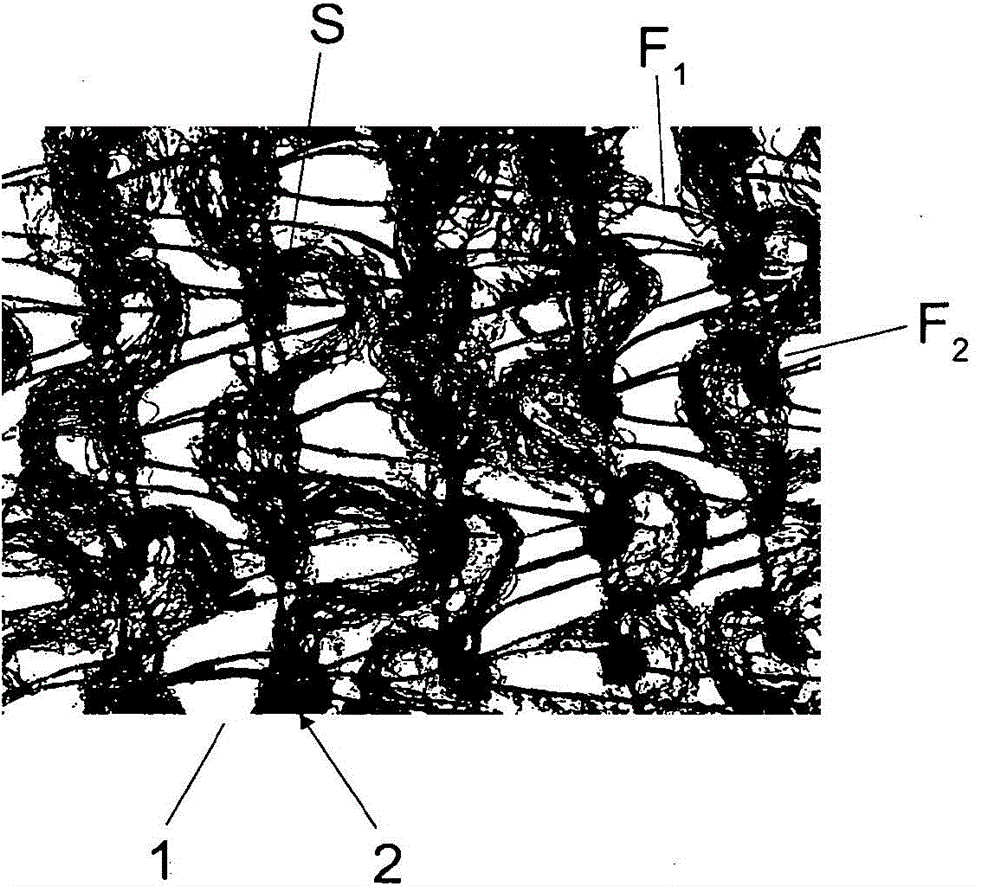

[0040] figure 1 A known composite material element for a Velcro fastener, in particular for a diaper fastener, is shown which has a carrier 1 in the form of a film and a textile material 2 bonded to the carrier 1 . The textile material 2 is a knitted fabric having a thread F made of a first base yarn 1 and the thread F of the second base yarn 2 Woven base structure.

[0041] In addition, loop threads S are incorporated into the base structure by weaving, said loop threads forming loops for connection with Velcro hooks.

[0042] The carrier 1 and the textile material 2 are joined by an adhesive, not shown, which is arranged in a pattern with adhesive surfaces and adhesive-free regions. For example by EP 2 439 323 A1 figure 2 a The known "dog-bone" structure with intersecting, wavy bonding lines is suitable, wherein the surface coverage of the bonding surface is preferably about 20% and the average coating weight over the entire surface is 2g / m 2 . For example, one-compo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap