Dispenser for packaging bag production line

A technology of production line and dispensing machine, which is applied to the device and coating of surface coating liquid, which can solve the problems of low efficiency, high cost, manual dispensing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

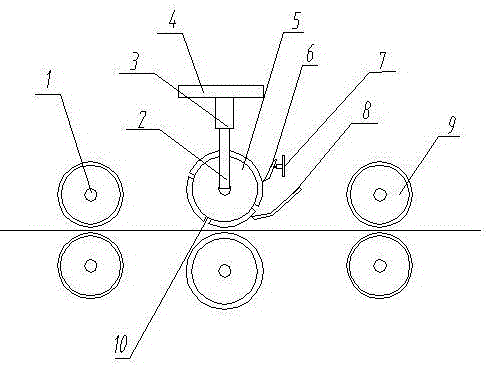

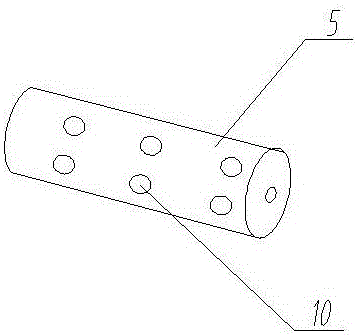

[0015] like figure 1 A dispensing machine for a packaging bag production line shown includes a frame 4 and a paper bag transmission mechanism, the frame 4 is arranged above the paper bag transmission mechanism, and the air cylinder 3 and the support 2 Connect the glue roller 5, the glue roller 5 is provided with a plurality of rubber grooves 10, a side of the glue roller 5 is provided with a rubber blocking plate 8, and the end of the glue blocking plate 8 is close to the The roller surface of the above-mentioned dispensing roller 5, and leave a gap of 3-5mm, the glue baffle 8 is used to place the glue, pour the glue on the glue baffle 8, and stick the glue on it when the dispensing roller 5 rotates , thereby realizing the gluing treatment of the dispensing roller 5 .

[0016] A scraper 6 is also arranged on one side of the glue dispensing roller 5 , and the scraper 6 is attached to the glue dispensing roller 5 . The scraper 6 is installed on the scraper mounting frame 7, an...

Embodiment 2

[0018] As a supplement of Embodiment 1 of the present invention, a cover body can be set on the glue tank 10 of the dispensing roller 5, and after the cover body is covered, the outer surface of the cover body is compatible with the roller surface of the dispensing roller 5, so that According to the needs of dispensing, select the glue tank 10 in some areas to use. For the unnecessary parts, you only need to cover the cover, which can adapt to the dispensing treatment of packaging bags of different specifications, without changing the dispensing roller, suitable for wide range.

[0019] A glue dispensing machine for a packaging bag production line provided by the present invention has a simple structure and is easy to operate. By setting a dispensing roller and a glue groove on the dispensing roller, the dispensing roller is glued through a glue blocking plate, and Use the scraper to scrape off the glue on the dispensing roller, and only keep the glue in the glue groove, so as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com