Screening and winnowing machine for sand and stone

A technology of air separator and screening machine, which is used in the separation of solids from solids by air flow, solid separation, chemical instruments and methods, etc., can solve the problems of quality requirements, large floor space, small output, etc. Efficiency of grading and powder selection, reduced vibration mass, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Further illustrate the present invention below in conjunction with accompanying drawing.

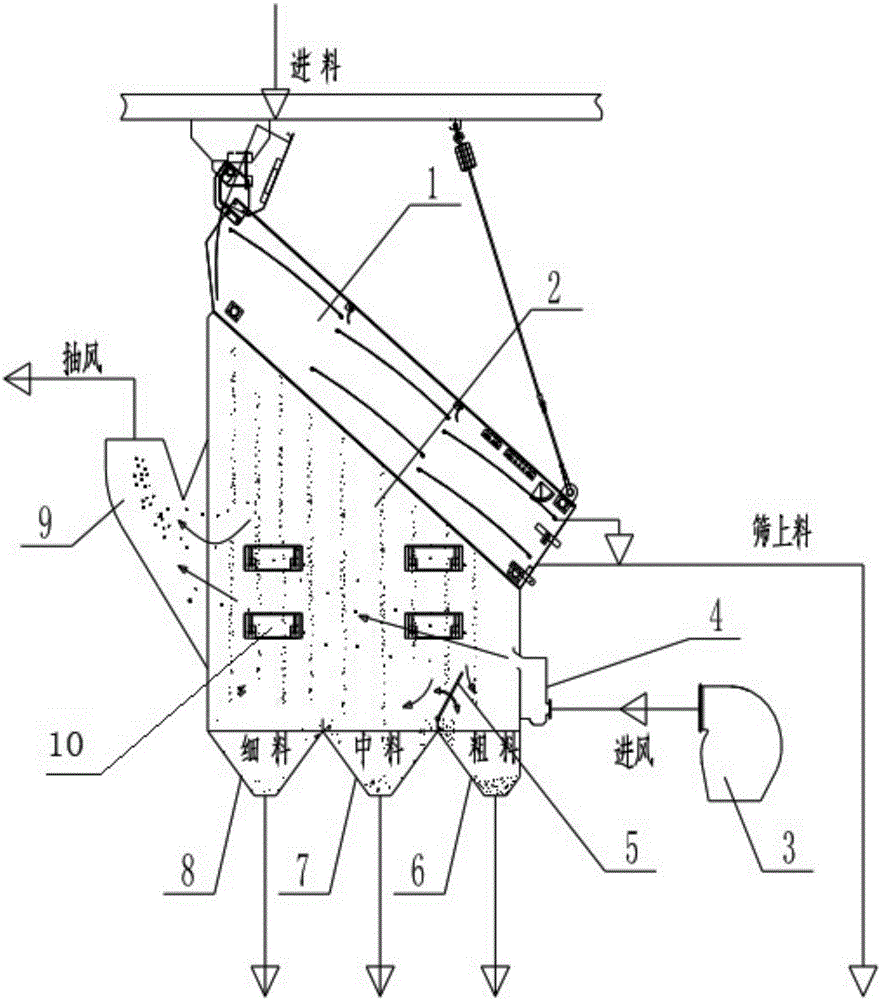

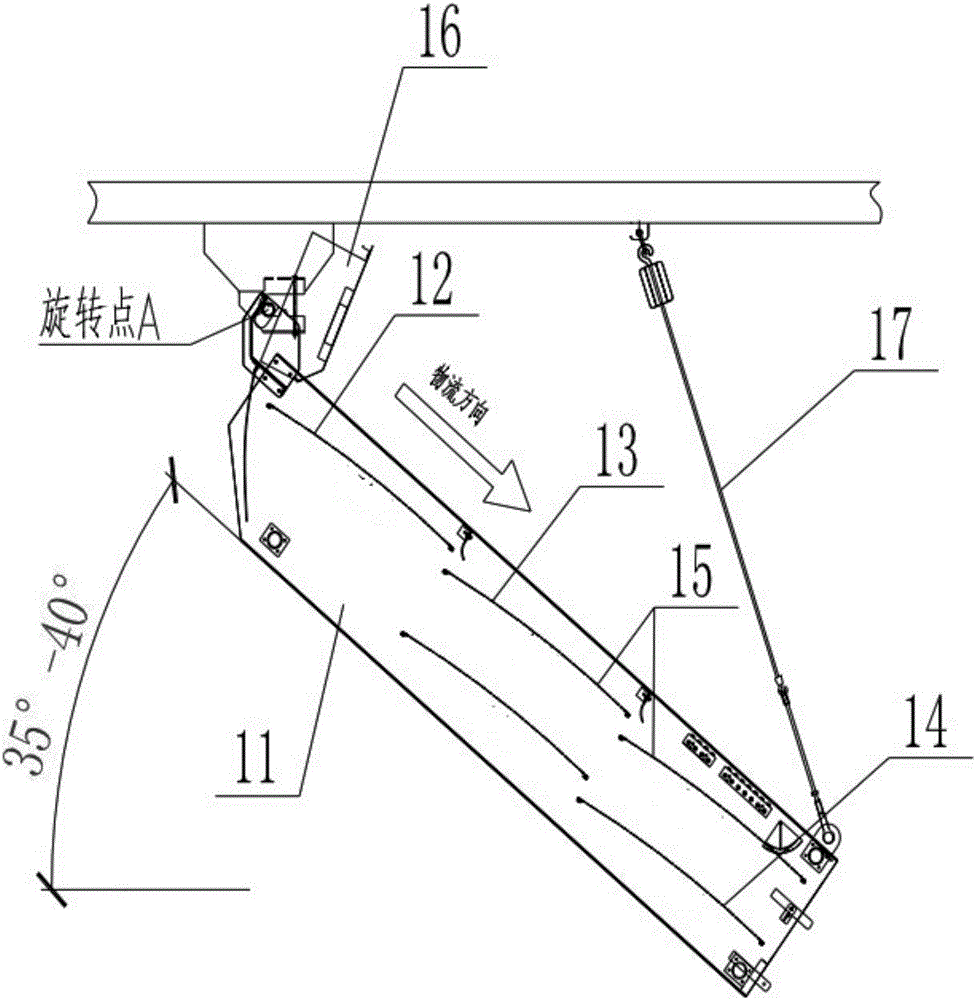

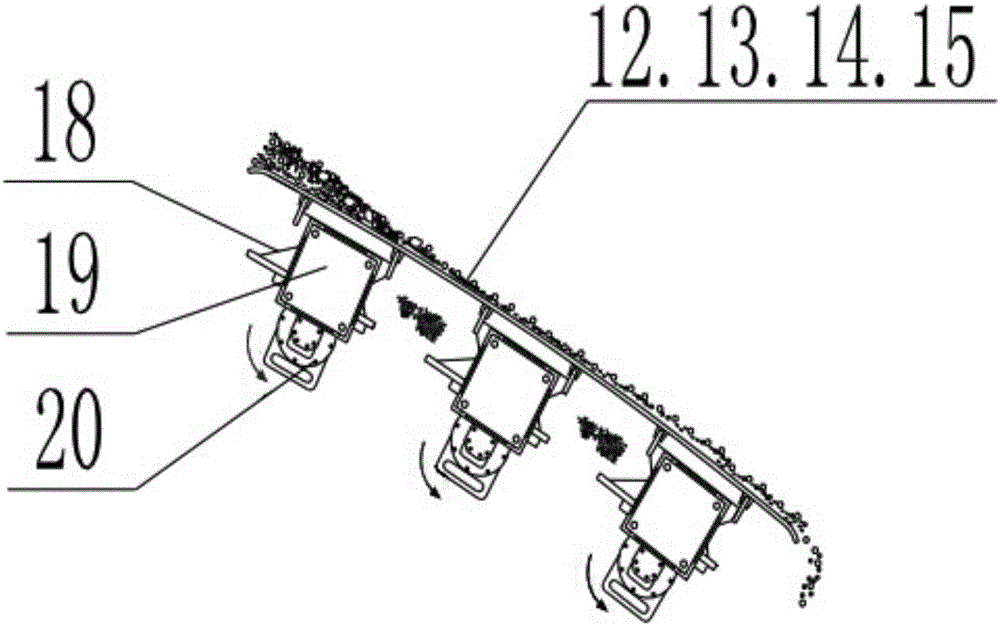

[0025] Such as figure 1 As shown, a screening winnowing machine for sand and gravel includes a screening machine 1, a winnowing bin 2, a blower 3, an air inlet channel 4, and an air extraction channel 9, and the screening machine 1 is installed on the upper part of the winnowing bin 2 , the material falls into the winnowing bin 2 after being screened and dispersed by the screening machine 1. One end of the winnowing bin 2 is provided with a main air inlet. The other end of the selection bin 2 is provided with a draft outlet, which is connected to the draft passage 9, and the lower part of the wind selection bin 2 is provided with a plurality of collecting hoppers; Under the action of wind force, the stone powder in the material under the sieve is taken away by the wind, and the material that has been screened and air-selected falls into the corresponding collection hopper. Three ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com