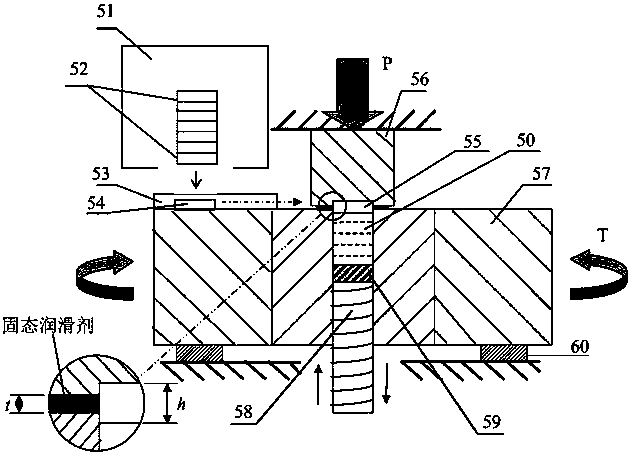

A high-pressure torsional stacking manufacturing method and device

A high-pressure torsion and manufacturing device technology, which is applied in the direction of manufacturing tools, metal processing equipment, forming tools, etc., can solve the problems of small thickness of metal sheets, no significant improvement in mechanical and physical properties of materials, and limited range of material selection, etc., to achieve workpiece The effect of large size, significant industrial application prospects, excellent mechanical properties and physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The solution chosen in this example is to first subject the high-purity aluminum discs with annealed coarse grains (average grain size ~200 μm) to high-pressure torsional deformation for more than 25 turns one by one to obtain a uniform fine structure with an average grain size of ~8 μm. Then these disc workpieces are used as raw materials for high-pressure torsion additive manufacturing, and high-pressure torsion composite and additive manufacturing are carried out. For each disc workpiece stacked, only about 5 rounds of high-pressure torsion are required, and finally a whole in the metallurgical sense is obtained. High-purity aluminum rod-shaped workpieces.

[0058] The initial state of ultra-high-purity aluminum is annealed (200°C, 1 hour), such as Figure 9 As shown, the average grain size is ~200μm, and the grain boundaries are straight, which is a typical annealed structure. Process it into a disc with a diameter of 30mm and a height of 1.2mm. After passing throu...

Embodiment 2

[0060] In this embodiment, the scheme of simplifying the process is adopted, and the annealed coarse-grained (average grain size ~200μm) high-purity aluminum disc is directly used as the raw material for high-pressure torsional additive manufacturing, and high-pressure torsional composite and additive manufacturing are performed. , about 25 turns of high-pressure torsion are required to ensure that the metallurgical bonding between the discs is achieved, and the microstructure is uniform and stable, and does not change with further deformation, and finally obtains a metallurgical sense with an average grain size of less than 10 μm. It is a whole high-purity aluminum rod-shaped workpiece.

[0061] The initial state of ultra-high-purity aluminum is annealed (200°C for 1 hour), such as Figure 9 As shown, the average grain size is ~200μm, and the grain boundaries are straight, which is a typical annealed structure. It is processed into disks with a diameter of 30mm and a height ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com