Wave soldering fixture for automatically soldering intelligent water meter

A wave soldering fixture and automatic soldering technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inconvenient operation, waste of resources, poor versatility, etc., to achieve novel structure and improve production efficiency , Design unique effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

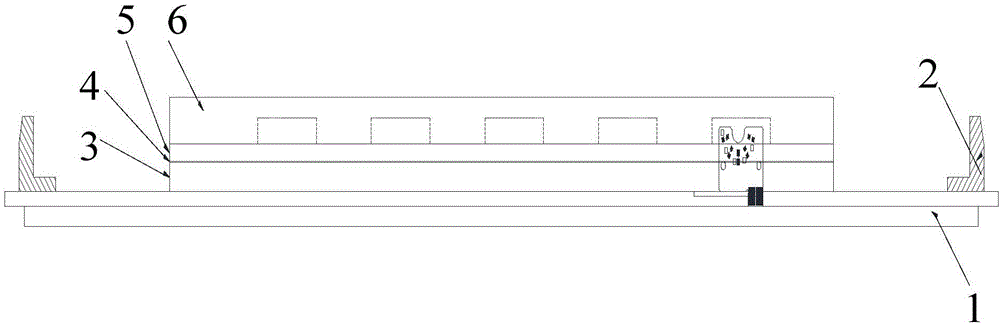

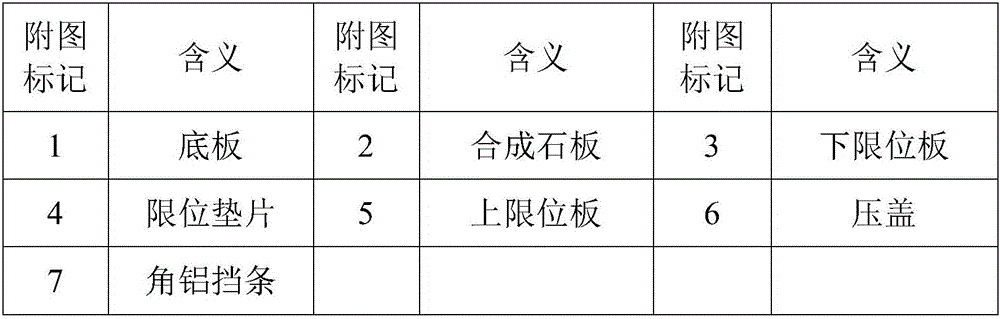

[0020] like figure 1 As shown, the wave soldering fixture for automatic welding of intelligent water meters includes a bottom plate 1 and a synthetic stone plate 2, a lower limit plate 3, an upper limit plate 5, and a gland 6 placed on it in sequence. The synthetic stone plate 2 is provided with multiple It is used to place the welding accommodation slot for the CPU board. The lower limit plate 3 is placed on the synthetic stone plate 2, and the lower limit plate 3 is provided with a hollow hole for the CPU board accommodation limit and a GDB for the position opposite to the welding accommodation slot. The hollow hole for the plate accommodation limit, the upper limit plate 5 is arranged on the lower limit plate 3, and the upper limit plate 5 is provided with a hollow hole for the accommodation limit of the GDB plate on the part opposite to the welding accommodation groove, and the upper limit plate 5 A gland 6 is installed. In addition, as required, a spacer 4 of different t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com