Automatic Roll Grinding System

A roll grinder, automatic technology, applied in the direction of grinding machine parts, grinding/polishing equipment, grinding automatic control device, etc., can solve the problems of low degree of automation and no automatic solution, so as to increase operating efficiency, The effect of saving grinding auxiliary time and avoiding misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

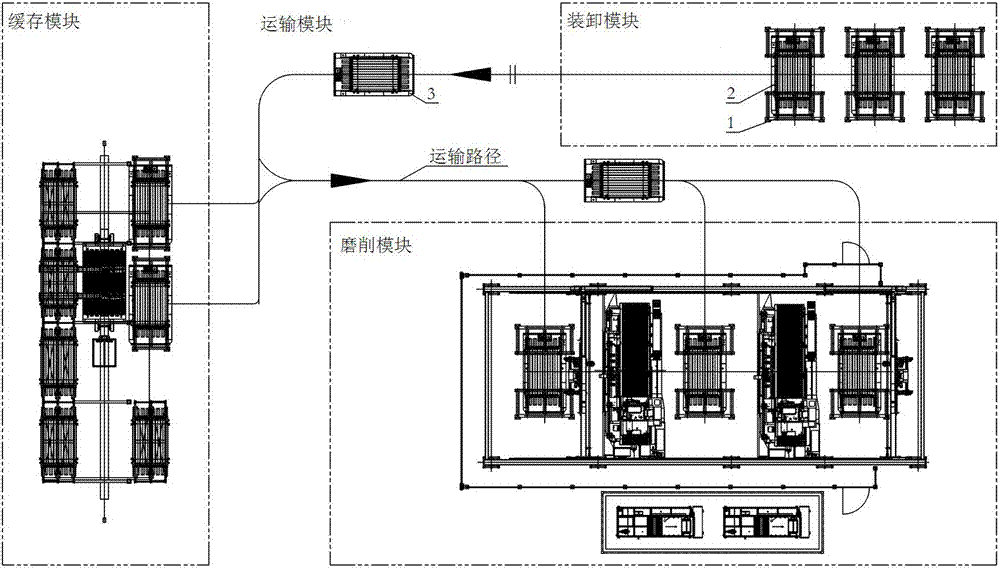

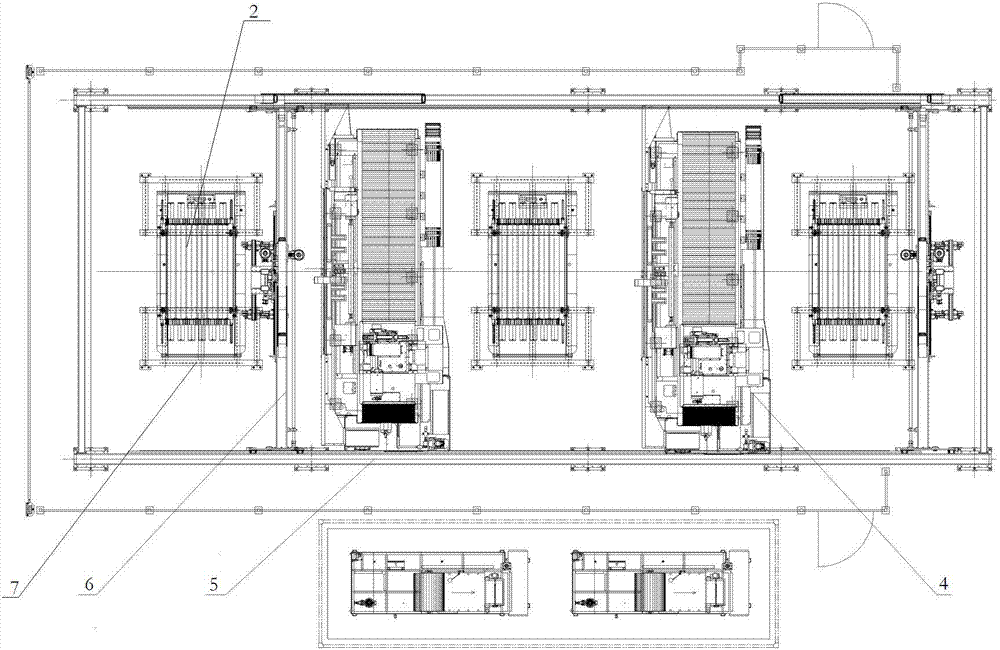

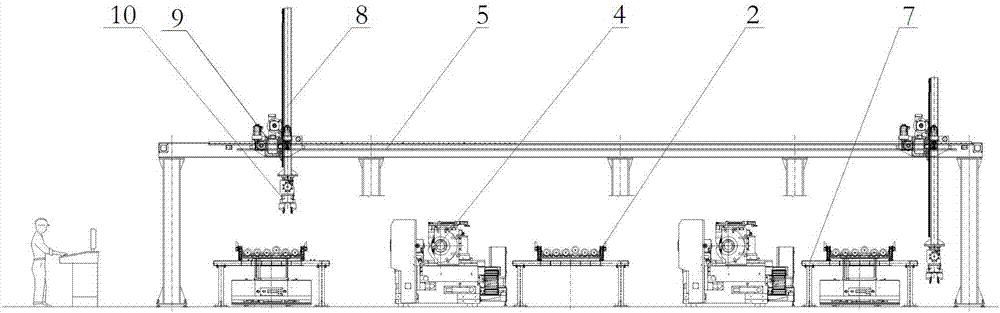

[0034] Such as figure 1 As shown, an automatic roll grinding system includes a loading and unloading module, a grinding module, a buffer module, a transport module, and a control module for two-way communication with the above modules (the automatic equipment in it), respectively; the loading and unloading module is located near the rolling mill, including The roll box 2 for placing the roll, the loading and unloading roll box frame 1 for placing the roll box 2, and the lifting device for lifting the roll and the roll box 2; the grinding module includes an automatic roll grinder 4, which is located near the automatic roll grinder 4 The grinding roll box frame 7 and the automatic feeding device for placing the roll box 2, the automatic feeding device includes a manipulator 10 that can move to any position above the automatic roll grinder 4 and the grindi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com