Milling machine with atomizing dust removing and cooling functions

A grinding machine and functional technology, which is applied in the field of grinding machines and grinding machines, can solve the problems of complex structure of grinding machines, lack of dust removal and cooling functions, etc., and achieve the effect of good spray cooling and dust removal, novel structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

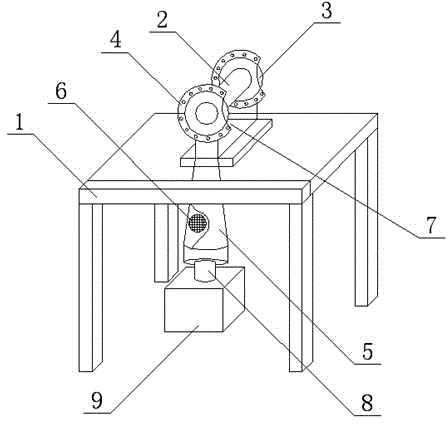

[0014] see figure 1 , a kind of grinder that the present invention relates to has the function of spray dust removal and cooling, comprising a frame 1, a motor 2 is installed on the workbench above the frame 1, and a grinding wheel 3 is respectively installed at both ends of the output shaft of the motor 2. The outside of emery wheel 3 is provided with water spray cover 4, and the periphery of water spray cover 4 is provided with a plurality of water spray holes towards emery wheel 3, and water spray cover 4 is provided with grinding port 7 at the grinding position of emery wheel 3, and water spray cover The bottom of 4 is connected with one end of collecting pipe 5, and micro-water pump 6 is installed on the collecting pipe 5, and the bottom of collecting pipe 5 is provided with circulating water tank 9, and the water inlet of micro-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com