Semi-automatic pencil sharpener

A pencil machine, semi-automatic technology, applied in sharpening devices, printing, office supplies, etc., to achieve the effects of alleviating eye fatigue, saving time, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

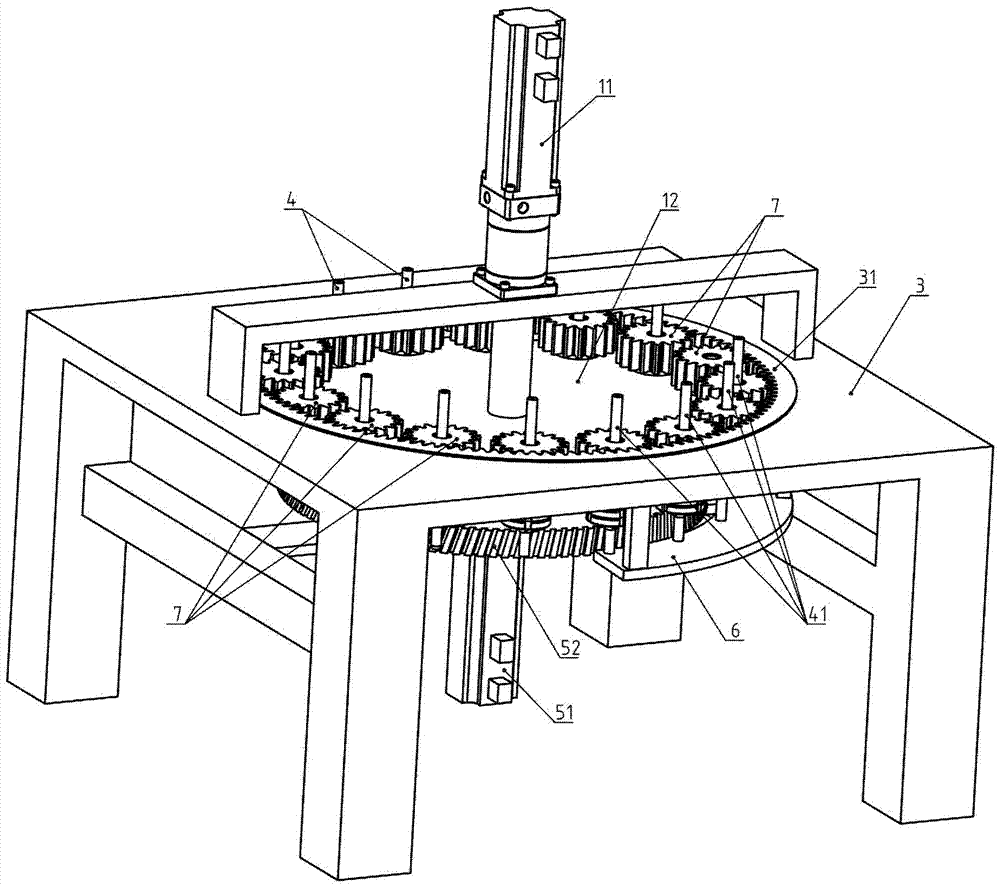

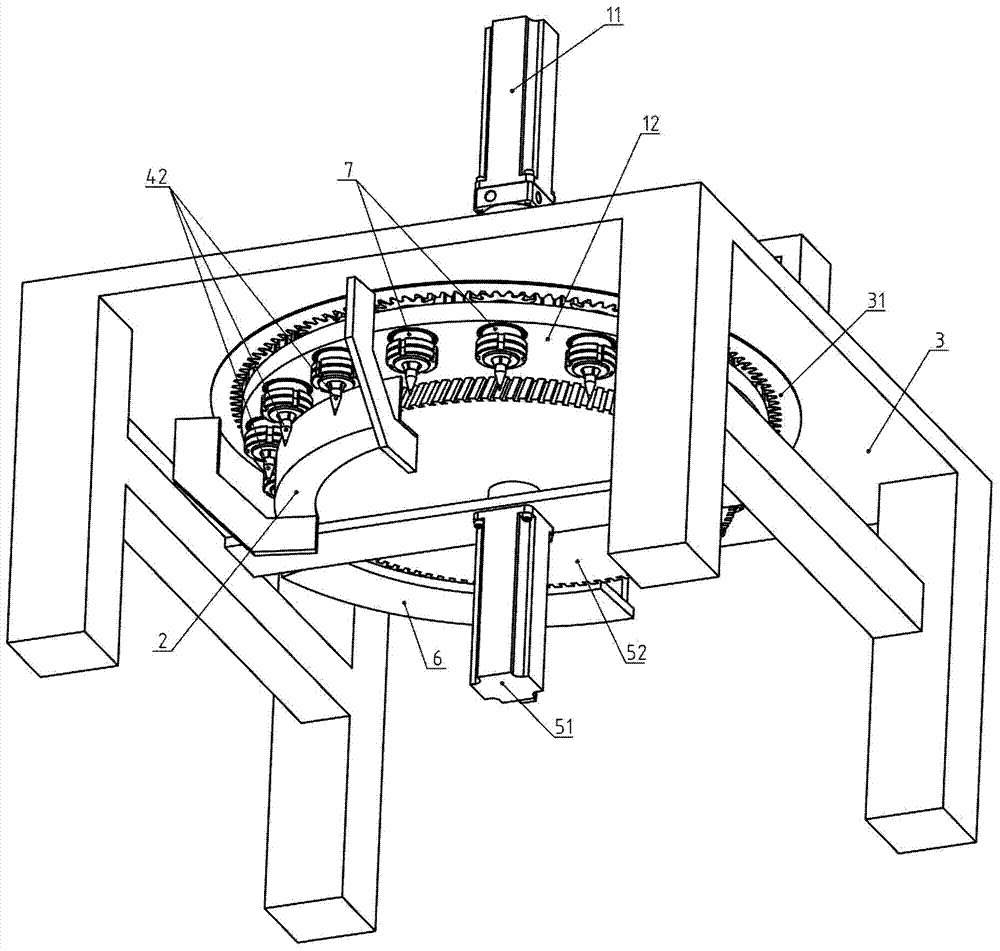

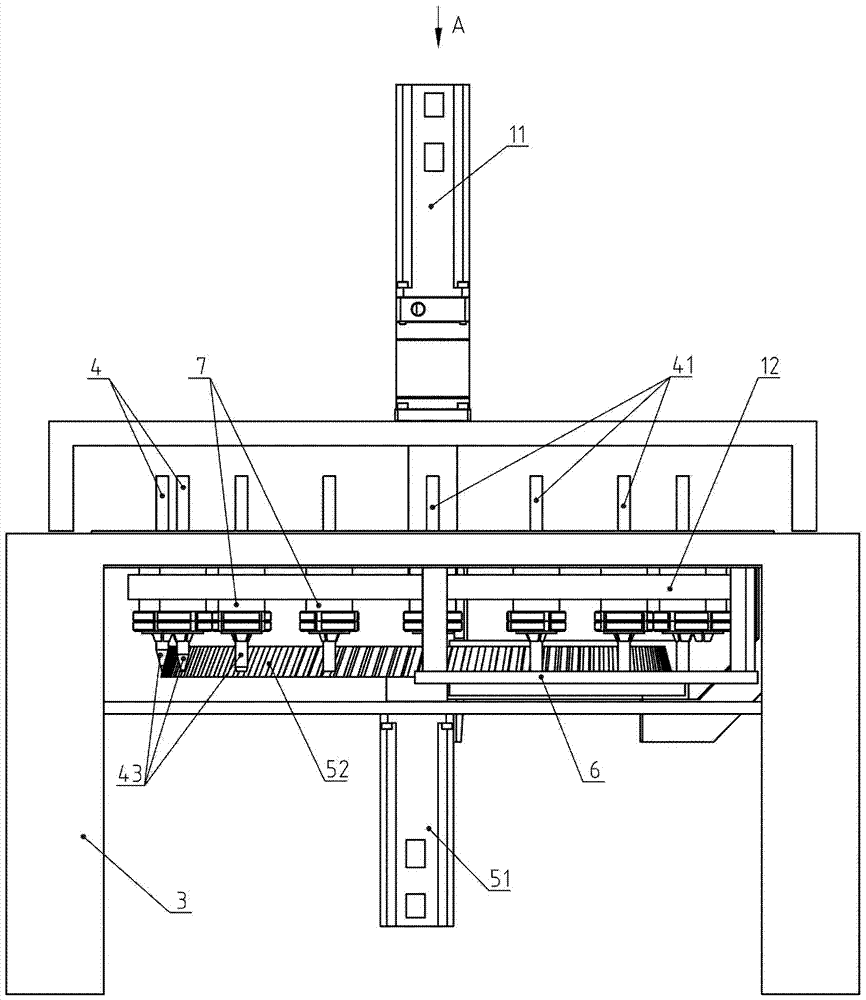

[0054] Example: see Figure 1 to Figure 14 .

[0055] A semi-automatic pencil sharpener, comprising a frame 3, a rotating motor-reducer combination 11, a rotating disc 12, a cutting motor 51, a cutting disc 52, and a plurality of pencil fixing assemblies 7;

[0056] The inner gear ring 31 is arranged horizontally on the frame 3;

[0057] The rotating disk 12 is disc-shaped, with a hub 122 in the middle, and a plurality of mounting holes 121 arranged on the edge;

[0058] The fixed flange of the combination 11 of the rotating motor-reducer is fixedly connected with the frame 3, and the output shaft of the combination 11 of the rotating motor-reducer is fixedly connected with the hub 122. When the combination 11 of the rotating motor-reducer is energized and rotates, it drives Rotating disk 12 rotates;

[0059] Pencil fixing assembly 7 comprises pinion 71, jump ring 72 and bearing 73, and pencil fixing assembly 7 is installed in the installation hole 121 by bearing 73, and pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com